Segmented Tyre For Vertical Mill

Flexco 56134 TGB8/2034/448/1219 Segmented Transfer ...

Flexco 56134 TGB8/2034/448/1219 Segmented Transfer Plate Kit For Horizontal to Horizontal or Waterfall Appliions View additional description. Typically ships in: 1 day Weight: lb; Unit of measure: each; Each. FREE SHIPPING ON ORDERS OVER 1. Select Quantity — + ADD TO CART. Returnable: See conditions. Payment methods: Return policy. Item must be unused. Item must .

Grinding roller for vertical roller mill

Vertical roller mill is the core equipment of modern grinding system. The grinding roller is the vital grinding component of vertical mill. Because the grinding roller can directly exert force on the material, the grinding roller has high requirements for hardness and wear resistance in actual CHAENG grinding rollers have the ...

Rotary Kiln Maintenance Procedures

because vertical shell deflection due to gravity may not be the same uphill and downhill of a tire. 6. The tire and support roller radiuses do not vary by more than .010". A tapered tire or roller tilts the plane of the tire relative to the kiln axis, causing high tire stop block loads and excessive support pad wear. 7. The shell must be ...

Understanding CircleSegment Milling Tools | Modern ...

· Understanding CircleSegment Milling Tools. The circlesegment cutter represents a class of milling tool in which the CAM software is key for using the tool effectively. Cutting profiles presented at the proper angles realize cycletime reductions in contoured workpieces such as molds. A CAM company engineer discusses the role of this tooling.

Grinding roller for vertical roller mill

Vertical roller mill is the core equipment of modern grinding system. The grinding roller is the vital grinding component of vertical mill. Because the grinding roller can directly exert force on the material, the grinding roller has high requirements for hardness and wear resistance in actual CHAENG grinding rollers have the characteristics of high hardness, good crack ...

Superior Weld Overlay Process Extends Life of Vertical ...

Hard facing, or weld overlay, of pulverizer wear parts (grinding rolls/tires and table/bowl segments) for vertical spindle mill pulverizers has been in use, in various forms, for over 30 years. In the early 1970s, the process of applying a high chromium weld wire to rebuild worn pulverizer grinding rolls started to replace the practice of replacing worn out grinding rolls with new rolls ...

LOESCHEMILLS

roller mills (vertical airswept grinding mills) since the second half of the 20th century. Loesche was and is the pioneer of this technology. Hundreds of Loesche mills have been used in the cement industry across the world to the present day. They operate with two, three, four and six roll ers.

Deformability of Shredded Tires

strains of % and % at vertical stresses of 69 kPa (10 psi) and 276 kPa (40 psi), respectively. Newcomb and Drescher (1994) calculated a value of Young's modulus for shredded tire material based on experimental constrained modulus and coefficient of lateral earth pressure values from tests on laterallyconstrained samples. For pieces 50

Different Types of Milling Cutters Used in Machining ...

We use end mill more in the vertical milling processes. Highspeed steel or the cemented carbide are used to create end mills. High speed steel is also called as HS or HSS. The high speed steel doesn't loose its hardness when the temperature increases. Hence, due to better hardness the high speed steel is used to make end mills. The end mills are mostly used in plunging, tracer milling, face ...

Mill technologies from the leading innovator | Gebr. Pfeiffer

We are the pioneers of vertical roller mill technology. The inventors of mill drives with more than 10,000 kW, modular ready2grind systems and gypsum calcination in vertical roller mills. The worldwide soughtafter specialist for innovative solutions, with its own development department and .

: 14 inch bandsaw wheel

3 Pack Bandsaw Tires for Woodworking Projects Urethane Light Bands for Saw Replacement14 inch x 1 inch x .095 for Easy CheckupBlades Wheel ExtensionDamage Resistanc. out of 5 stars 39. 16. 99. Get it as soon as Wed, Nov 3. FREE Shipping on orders over 25 shipped by Amazon. More Buying Choices (2 used new offers) 2 Pack Urethane Band Saw Tires, Be Applicable 1" .

CEMENT AND UTILITIES LABLAORTYESTIRERN˜˚˛˝˙ˆ˛ˇ˘ ONE WORLD ...

Xwin ® and neoX ceramicbased technology is available for grinding elements in most vertical spindle mill appliions, tires/rolls and tables. They combine the extreme hardness of ceramic with the mechanical properties of high chromium metal providing unsurpassed performance. The result is maximum wear resistance and wear life.

Compressibility of tyres for use in landfill drainage ...

At vertical stresses greater than about 80 kPa, however, the differences on a graph of dry density or porosity plotted against vertical stress are much smaller. The proportion of voids that are not freedraining decreases with compression for whole tyres, as cuplike structures capable of retaining water flatten out. For tyre chips, the proportion of nondrainable voids increases with ...

Tyre Curing Press, Bag O Matic Tyre Curing Presses, Tube ...

Tyre Curing Press. Specific Engineering Corporation manufactures a wide range of twin cavity platten type as well as dome type mechanical presses, capable of generating closing force upto 350 tonns and above per mould. All presses are conventional double ended BagOMatic type with capability for segmented mould for radial tyre.

PartMaker SwissCAM Fundamentals : 4 Steps

Step 2: Screw. Instructional video and files to program a Swiss part with segmented turning, threading, and cross milling on a Swiss lathe with PartMaker. This tutorial includes videos to program from print and solid model. Attachments.

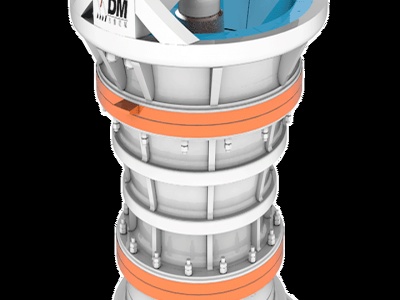

CHAENG vertical mill grinding roller tyre

· The advantages of vertical mill roller tyre produced by CHAENG are as follows: 1. Adopt ZG30Mn, with high hardness and good wear resistance. 2. Professional flaw detection instrument testing and quality assurance. 3. The rocker arm can be turned out of the mill for easy maintenance. 4. Smooth surface, beneficial to increase grinding efficiency. 5. High hardness, good anticracking and fine ...

Latest Posts

- تكلفة المشاريع الصغيرة كسارة الحجر

- تصنيع مكائن صناعة الطاحونة في مصر

- الألومنيوم إعادة تدوير المعدات خبث في مصر

- معدات غسل الفحم في مصر

- مصنع الكرة مطحنة في جودبور

- تجميع البكرة المحبوبة مع الحزام الناقل

- تكلفة بناء واستكمال محطة التعدين

- تستخدم كسارة خام المعادن السعودية تكلفة

- آلات الصابورة للبيع في العراق

- مصنع تكسير رمل الحصى في مصر

- شاحنات مستعملة للتعدين في مصر

- كرة صغيرة السعر مصنع

- خط إنتاج بولي طحن الحجارة

- كسارة مخروطية ما هي الأنواع المختلفة

- نماذج طاحونة الرطب والأسعار

- Stone Crusher New Technology

- Hammer Mills In Nairobi Prices

- Ex200 2 Nakayama Crusher

- Mini Portable Jaw Crusher For Sale Approved Ce

- Ground Rock Phosphate

- Iron Ore Mining Crusher

- Overland Conveyor Russia

- Cyanite Milling Process Price

- Gear Grinding Level

- Cs 75 Ne Crusher

- Ambuja Cement Foundation Sanand

- Vertical Mill Thread Insert

- Katup Mesin Refacing Afrika Selatan

- Stone Crusher Behat Bann By Govt

- Durable Grinding Machine Supplier