Ore Functions Ball Mill

Grinding Media Balls for Mines and Minerals Processing ...

There is no standard solution for mineral industry and wear rate of grinding media varies from mine to mine, ore to ore and even for the same ore time to time. Different alloys are recommended depending on ore type and mill particulars in order to arrive at the most cost economic solution. Based on our world wide experience, AIAE can help select optimum alloy for specific appliion ranging ...

Comminution testing

· Measuring ore grindability in balls mills. The Bond Ball Mill Work Index is a measure of the resistance of the material to grinding in a ball mill. It can be used to determine the grinding power required for a given throughput of material under ball mill grinding conditions. It is a 'locked cycle' test conducted in closed circuit with a laboratory screen. The Bond Ball Mill Work Index can be ...

IAMGOLD Corporation

Ball Mill: A large steel cylinder containing steel balls into which crushed ore is fed. The ball mill is rotated, causing the balls to cascade and grind the ore. Bench: Horizontal steps/increments mined as an open pit progresses deeper. Bull market: Term used to describe financial market conditions when share prices are going up. Byproduct : A secondary metal or mineral product recovered in ...

Rod mills, how they function

Rod mills are very similar to ball mills, except they use long rods for grinding media. The rods grind the ore by tumbling within the the mill, similar to the grinding balls in a ball mill. To prevent the conditions leading to rod charge tangling, the length to diameter ratio is maintained at to Rod mills accept feed up to about 50 mm (2 in.) and produce a product in the size range of ...

Estimated Water Requirements for the Conventional ...

water usage. The crushed ore is transferred to a semiautogenous (SAG) mill or ball mill where the ore is further reduced in size. Water is added to the ball mill, in which a slurry that usually contains from about 20 to 55 percent solids is produced (Singh, 2010; International Mining, 2011) (see fig. 2). The

Metso Ball Mills Brochure

Ball mills designed for long life and minimum maintenance Metso overflow ball mill sizes range from 5 ft. x 8 ft. with 75 HP to 30' x 41' . and as much as 30,000 HP. Larger ball mills are available with dual pinion or ring motor drives. Our mills incorporate many of the qualities which have made the Marcy name famous since 1913.

Ball Mills | Industry Grinder for Mineral Processing ...

Ball Mill for Sale In all the ore mining beneficiation and concentrating processes, including gravity separation, chemical, froth flotation, the working principle is to prepare fine size ores by crushing and grinding often with rock crushers, rod mill, and ball mils for the subsequent treatment. Over a period of many years of development, the fine grinding fineness has been reduced many times ...

Ball Mills

Most ball mills operate most efficiently between 65% and 75% of their critical speed. Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant. Photo of a series of ball mills in a Copper Plant, grinding the ore for flotation. Image of cut away ball mill, showing material flow through typical ball mill. Flash viedo of Jar Drive and Batch Ball Mill grinding ore for testing. Return To ...

Beneficiation Plants and Pelletizing Plants for Utilizing ...

A ball mill is equipment that solely uses steel balls to grind ore, and its shell body has a smaller diameter and longer length compared with an AG mill or with an SAG mill. Separation The ground material is separated into useful ore and impurities in a separation process. Two types of separators:, a separator based on the difference in Fig. 1 Example of process flow in ...

AN INTRODUCTION TO COPPER EXTRACTION

Ball mill ... Figure 44: Sequence function block enabling MHI interaction..... 59 Figure 45: Transition condition for high pressure pumps..... 61 Figure 46: Mill control system example code 1 from vendor..... 64 Figure 47: Mill control system example code 2 from vendor..... 65 Figure 48: Function description developed..... 65 . ENG450 ENGINEERING INTERNSHIP MURDOCH UNIVERSITY AUSENCO ...

Firstorder and secondorder breakage rate of coarse ...

function, and n is the order of equation. Loveday (1967) and Austin (1971) have found experimentally that, in the case of batch grinding, the breakage rate obeys a firstorder law or n=1. However, there is no valid reason for this. Firstorder and secondorder breakage rate of coarse particles in ball mill grinding 269 If the total mass load in the mill is at particle size i=1 (singlesized ...

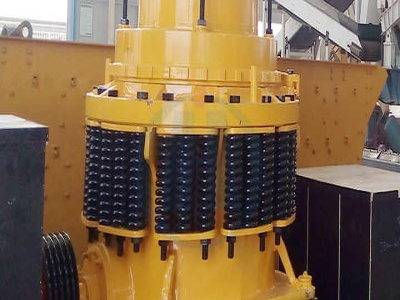

Ball Mill Liner Function

Ball Mill Liner Function. Ball mill is a major equipment in the production of power plants, cement plants, mines, chemical industry, metallurgy and other industries, the liner is one of the components of the mill, the main role is to protect the cylinder, the cylinder from the grinding body and Material direct impact and friction, help to improve the mill grinding efficiency, increase ...

Ball Mills

Ball Mills. Ball mills have been the primary piece of machinery in traditional hard rock grinding circuits for 100+ years. They are proven workhorses, with discharge mesh sizes from ~40M to <200M. Use of a ball mill is the best choice when long term, stationary milling is justified by an operation. Sold individually or as part of our turnkey ore processing system. For questions and/or an ...

ball mill parts and functions

ball mill parts and functions. about ball mill and function of machinery parts. MQ Ball Mill VFLO. exploit the cementation function of bentonite to the full, intensify the strength of the a. using the ball mills, the technical ask for high enquiry about material size. b. .. steel, 10,000 ton mechanical part and 30,000 ton machine products.

Grinding Mills

4′ x 4′ cominco sullivan rubber lined ball mill, 25 hp; id: l01573. 4′ x 4′ dominion skid mounted ball mill; id: l02241. 4′ x 4′ eimco ball mill, 30 hp; id: l02357. 4′ x 4′ marcy ball mill, 50 hp; id: l01551. 4′ x 5′ colorado iron works steel lined ball mill, 25 hp; id: l01922. 4′ x 6′ denver rubber lined ball mill, 40 hp; id: l02355. 4′ x 8′ denver ball mill, 50 hp ...

Ball mills

Metso Outotec has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a wide range of appliions. Some of those appliions are grate discharge, peripheral discharge, dry grinding, special length to diameter ratio, high temperature milling oprations and more. All equipment adheres to the applicable ...

Grinding Mills

Nelson Machinery sells new used grinding mills including ball mills, SAG mills, tower mills, Raymond roller mills. Equip yourself with the gold standard

Grinding Crushing Mill

VIBRADRUM® Grinding Mills excel over conventional ball, stirred media, or vertical roller mills in both grinding and energy efficiency. The features listed below highlight why our mills are so effective and efficient. Proven energy savings range from 35 to 50% reductions in kW hours per ton of processed material. 5 to 10 times longer media life. No trunnions, wheels, gears, or drive reducers ...

About Us

About Us. JXSC Mine Machinery Factory is an experienced supplier of Mining Equipment including stone crusher machine, gravity concentration, magnetic separation, feeder equipment, mining laboratory equipment, provides EPC service. Since rugged start at 1985, JXSC has been accumulating rich experience on various mineral processing plants, cover ...

Emax

The High Energy Ball Mill Emax combines highfrequency impact, intensive friction, and controlled circular jar movements to a unique and highly effective size reduction mechanism. The grinding jars have an oval shape and are mounted on two discs respectively which move the jars on a circular course without changing their orientation.

Simulation of a ball mill operating with a low ball charge ...

The energy specific selection function was determined in the torque mill operating under the same operational conditions except for the ball size distribution. The Bond equilibrium ball size distribution was used because the ball sampling campaign did not achieve the desired accuracy. The test was performed with a % solid concentration, % ball charge level and 75% of the critical speed.

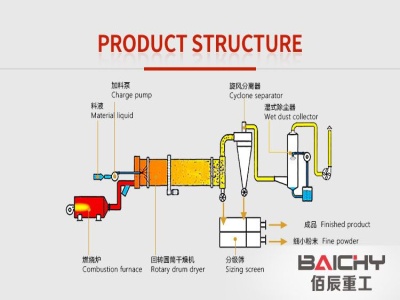

Genera Processing Technology For Minerals | Prominer ...

The complete mineral ore processing plant always includes crushing, grinding and beneficiation stages, and the beneficiation stage consists of different technology, mainly gravity separation, flotation, magnetic separation, chemical processing, etc. Prominer can customize the suitable technological process based on the mineral characteristics and supply full process solution. Crushing ...

Latest Posts

- كيفية تغذية كسارة الفحم

- معدات تكرير الفحم

- النحاس طحن خام طريقة

- تحويل وصب عملية التعدين

- بحاجة إلى فك متنقل مع كسارة مخروطية للعمل في

- آلة كسارة الحجر تصنع في ولاية كيرالا

- توكو mesin كسارة دي سورابايا

- مطحنة الكرة محرك الأقراص المركزي

- 40 60 tph كسارات مخروطية الولايات المتحدة الأمريكية

- العمل ومبدأ طاحونة متناهية الصغر

- صخرة محطم أيون التعدين

- إنتاج الباريت في الإبدية

- طحن الباريت في عمان

- محطات الفحص المتنقلة للبيع

- رخصة كسارة حجر في عمان

- Hasil Mhada Untuk Pekerja Pabrik Saraswat Bank

- Cement Plant Operated By China In World

- Rock Breaker Manufacturers In Estonia

- Crusher Specs Pe Series

- Crusher Sand Locations In Tamilnadu

- Philippines Aggregate Philippines

- Bulldozer Construction Machinery Sales

- Harga Bijih Karbonat Ghana Mangan

- Mill Amp Amp Metallurgy Mining Jobs

- Installation Twin Pinion Sag Mill

- Small Scale Cocoa Mill

- Riotuba Nickel Mining Apparatus

- Concrete Plant Ball Mill

- Crusher Pdf Machines Manual

- Gambar Coal Mining Crusher Dibalikpapan