Alumina Process Of Flotation

Hydrochloric acid leaching for upgrading flotation ...

Bauxite is the major raw material for alumina production, and its Al2O3 grade improvement or desiliion is a necessary process for production of highgrade alumina concentrates from bauxite ores. In practice, flotation presents an effective method for the processing of such ores. However, it is not sufficient to produce a concentrate product with high Al2O3 grade from the ores with a single ...

Pioneering Studies on the Flotation of Corundum From a ...

A flotation process utilizing petroleum sulfonate as the collector in an acid circuit was devised. Results showed that two flotation schemes each produced a concentrate exceeding the national stockpile specifica tions for calcined bauxite. From a feed containing 28 pct corundum~ concentrates containing up to pct alumina (A1 203) were produced with a corundum recovery of pct. l ...

Recovery of Silicon and Iron Oxides from Alumina ...

Keywords: aluminacontaining wastes, sweepings, electrolytic aluminum production, flotation of sweepings, purifiion of sweepings, recycling DOI: /S INTRODUCTION Dusting and pouring of alumina and electrolyte occur during electrolysis aluminum production through leakages in construction elements of equipment, mechanisms, and motorized machinery. Herewith, .

Hydrochloric acid leaching for upgrading flotation ...

with the flotation process to produce an alumina concentrate, with its A/S ratio further improved using hydrochloric acid leaching to dissolve the carbonate minerals in the concentrate. The effects of three dominant parameters on the leaching performance, that is the leaching time, leaching temperature and hydrochloric acid concentration were investigated, and then a flotationleaching process ...

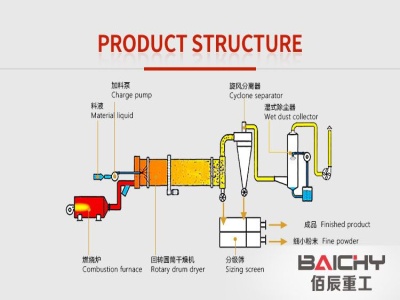

alumina processing equipment list

Alumina Processing Equipment List. Outotec alumina solutions,alumina from bauxite and nonbauxite raw materials. our integrated refinery concept features stateoftheart process technology and proprietary equipment and is designed to minimize energy and raw material consumption, as well as overall environmental impact. our processing alunite roast reduction using a modified bayer process

flotation of alumina

alumina process of flotation Froth flotation is a process for selectively separating hydrophobic materials from hydrophilic. This is used in mineral processing, paper recycling and wastewater treatment industries. Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th century. Get More; alumina process ...

History and Future of Phosphate Mining and Beneficiation ...

Flotation: Reverse Flotation . Amine float. (Elandsfontein process) Mine ore is upgraded from circa 8% P 2 O 5 to a final product of 30 % P 2 O 5 (Optimisation is continuing after commissioning. Kropz indied in a media statement that the plant will be operational December 2018) BENEFICIATION PROCESS OF THE ELANDSFONTEIN DEPOSIT (Varswater ...

Mineral Processing technologies in the Bauxite and Alumina ...

PDF | On Jan 1, 2008, Stephan Buntenbach published Mineral Processing technologies in the Bauxite and Alumina Industry | Find, read and cite all the research you need on ResearchGate

Dependence of morphology on anionic flotation of alumina ...

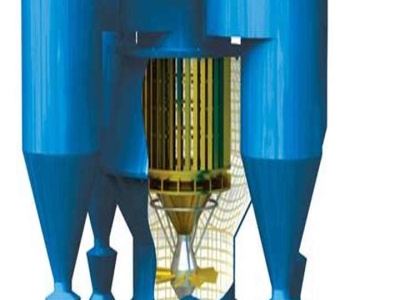

Column flotation, which is a very effective process in mineral processing especially for easily floatable minerals, is one of the most important new developments to emerge in mineral processing ...

INVESTIGATION AND OPTIMIZATION OF USE OF ANIONIC ...

flotation process is the most practical and widely applicable method in the bauxite industry. In the direct process, alumina minerals of diaspore are subjected to froth flotation. Researchers at Central South University and the Beijing Institute of Mining and Metallurgy carried out industry tests for bauxite beneficiation in 1999. The processing capacity of the industrial tests was 50 Mg of ...

Bauxite Beneficiation Flotation | Silica Iron ...

The most widely used chemical process of refining bauxite into alumina, the Bayer process, involves dissolving the Al2O3 out of the bauxite rock with caustic soda (NaOH) at elevated temperature and pressure. The Al2O3 fraction of the bauxite is dissolved into solution, to later be precipitated out as alumina. However, a highgrade bauxite contains up to 60% Al2O3, and many operating bauxite ...

(PDF) Processing of AluminaRich Iron Ore Slimes: Is the ...

Flotation process for concentrating iron ores received a big We have systematically investigated and reported earlier, impetus in USA immediately after the Second World War the possibility of achieving selective separation amongst due to the dwindling resources of direct shipping iron ores hematite–alumina–kaolinite–montmorillonite minerals, the in the Lake Superior District. Flotation ...

Processes | Free FullText | Effective Desulfurization and ...

In the flotation desulfurization process, raw materials need to be ultrafinely ground, and then sulfonate traps are used to collect pyrite by inhibiting water seepage, which is very difficult to control [8,9,10,11,12]. Desulphurization in the digestion process involves the addition of a certain amount of oxygen or hydrogen peroxide as oxidant to oxidize sulfide sulfur into sulfate radical ...

Mineral processing | Solvay

Mineral processing. Solvay's reagent portfolio includes offerings designed for the recovery of precious and base metals, such as copper, molybdenum, gold, nickel, cobalt, platinum group metals and polymetallics. We also offer products for various industrial minerals such as phosphate. Mining operations worldwide turn to Solvay to address ...

COLUMN FLOTATION FOR THE BENEFICIATION OF IRON ORE FINES

Reverse flotation (silica alumina is floated away from the concentrate) has proven to be an economical and effective method for reducing silica alumina content to acceptable levels. [3,4] Iron ore is being beneficiated all around the world to meet the quality requirement of Iron and Steel industries. However, each source of iron ore has its own peculiar mineralogical characteristics and ...

alumina process of flotation

Dissolved Air Flotation TheoryDissolved Air Flotation (DAF) is the process of removing, They must first be coagulated by a chemical such as the aluminum or,Separation of silica from bauxite via froth flotation,Separation of silica from bauxite via froth flotation, production of alumina refractories, tried direct flotation of the, silica through a flotation processAluminum Ore Flotation ...

alumina process of flotation

Froth Flotation Process . During the alumina production process by Bayer process with flotation,concentrates having A/S=10 or more are produced after diaspore type bauxite is treated with flotation process,resulting in more organic substances in the subsequent Bayer process paper analyzes the influence of organic substances on the subsequent Bayer process production and .

Role of Surfactants in Mineral Processing: An Overview ...

· Froth flotation process can be effectively applied to the system where more amount of fine liberated valuable and gangue mineral grains are present rather than of interlocked forms . Froth flotation, being an established method, has been known in a century's practice across the globe for its efficiency to eliminate impurities from different ores to produce good grade concentrate. Froth ...

FLOTATION OF ALUMINA FROM GIBBSITE BEARING–SHALE OF .

the major constituents of the ore. Flotation process was then selected as a suitable and effective method for the concentration and upgrading of alumina from gibbsite bearing–shale of south western Sinai to make it suitable for the Bayer process. Many researchers [413] have studied the flotation of alumina using different

USA

A process for the extraction of alumina from aluminumcontaining silies is disclosed. The process comprises acid leaching of the raw material, iron extraction, precipitation of the aluminum fraction as the aluminum chloride hexahydrate, removal of sodium chloride and calcination to alumina. The process can be made continuous with substantial regeneration and recycling of process components.

Laboratory Column flotation studies for reduction of ...

Keywords: Iron ore; slimes; column flotation; alumina reduction; reverse flotation 1. Introduction The Government of India highlighted Processing and utilization of iron ore fines as a prerequisite to meet the domestic raw material requirements for the projected 110 million tonnes of domestic steel production by the year 201920 in the National Steel Policy announced in November 2005 (Sharma ...

Agglomeration and Flotation of Alumina Clusters Molten Steel

ISIJ International, Vol. 39 (1999), No. 5, pp. 426434 Agglomeration andFlotation of Alumina Clusters in Molten Steel Hirokazu ) Kenichi SORIMACH12)andTomomiNAKANISH13) Formerly Technical Research Laboratories. Kawasaki Steel Corp,, Nowat Technology Groupon the Environmentfriendiy Steelmaking Processes, TheJapan Researchand DevelopmentCenter for .

China's Bauxite and Alumina Industry

alumina since 2010. Flotation Bayer Process for High Sulfur Bauxite . Al 2 O 3 SiO 2 Fe 2 O 3 TiO 2 S Tailing Concentrate Ore Industrial Result of Desulfurization by flotation process(%) Flotation Bayer Process for High Sulfur Bauxite . Part Ⅲ Prospect of China Alumina Industry. 21 To effectively refrain ...

Latest Posts

- طاحونة العمودية لطحن الأسمنت في مصر

- حل من تكلفة استخدام كسارة الحجارة الفكية للبيع

- مصر آلة طحن الحجر السعر

- تهتز اقتران شاشات

- مطحنة الكرة منخفضة التكلفة لإنتاج نانو حشو

- آلة طحن الذهب المستعملة للبيع الأردن

- مصنع تعدين الكروم مصر

- مصنع آلة محطم من الولايات المتحدة الأمريكية

- أجزاء من الحجر الجيري محطم مصنعي

- قائمة شركات صناعة الإسمنت في المملكة العربية السعودية

- كسارات الصخور الذهب

- اتصالات كسارة الصين في المملكة العربية السعودية

- شركة آلة تكسير الحجر في مصر

- سحق وغربلة جوال في السعودية

- التسعير لاستئجار كسارة متنقلة

- Crusher In Los Andes Sale

- Principles Of Mineral Processing Maurice C Fuerstenau Pdf

- Lightweight Gold Ore Crusher

- Spares Components Wear Parts Jaw Crushers

- Flotation Cells For Sale Australia

- Alpine Stone Grinding Industries Email

- Hst Series Crusher

- Penambangan Bauksit Bawah Tanah

- Quartz Powder Plant Price In Senegal

- China Manufacturer Fine Crushing Machine Cone Crusher

- 48s Style D Gyrasphere Crusher Lmzgalogue

- Zenith Crusher Mobile Crusher

- Butterfly Le Top Wet Grinder 2 Ltrs Smart Review

- Belt Conveyor In Processing

- Small Scale Gold Waqshing Plant