Of Using Cone Crusher

Crushers and Their Types – IspatGuru

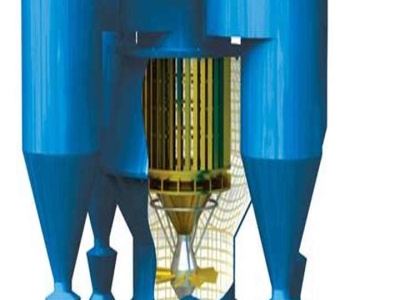

· Cone crusher is similar in operation to a gyratory crusher, with less steepness in the crushing chamber and more of a parallel zone between crushing zones. A cone crusher breaks material by squeezing the material between an eccentrically gyrating spindle, which is covered by a wear resistant mantle, and the enclosing concave hopper, covered by a manganese concave or a bowl liner.

MCO 110i PRO | Mobile cone crushers | Kleemann

The MOBICONE MCO 110i PRO mobile cone crusher stands out thanks to its extremely robust design and impressive performance. As an option, the plant can be operated via an external power source and impresses with its lowmaintenance operation. Extremely robust design. Very high production outputs with lowmaintenance operation.

Layout of a fourstage crushing plant for ballast ...

During use, a cone crusher concave liner suffers indentation (cold working) and abrasion; this combination provides the concave with a layer that constantly renews itself, maintaining a surface ...

The Advantages And Disadvantages Of Sand Cone | Crusher ...

11 Soils Field Procedures Using the Sand Cone Method. 111 CHAPTER ELEVEN: SOILS FIELD PROCEDURES USING THE SAND CONE METHOD Field density determination of soil compaction is done in accordance with. ... Cone crusher specifiion and advantages,calculate ...

Chamber Optimization for Comprehensive Improvement of Cone ...

Mar 15, 2021 · Finally, based on the iron ore coarsely crushed by the gyratory crusher, the dynamic characteristics of the C900 cone crusher were simulated by using the discrete element method (DEM), and the simulation results are basically consistent with the numerical analysis results.

4 Types of Rock Crushers to Acquire for Your Green ...

Aug 02, 2021 · Cone crushers. These crushers work by compression and can reduce building materials by squeezing and breaking them apart. They feature a rotating mantle and a concave bowl resembling that of the gyratory crusher. However, the crushing chamber isn't steeply angled as with a gyratory crusher. They can be used to crush mediumhard to abrasive ...

OnLine Optimization of Cone Crushers Using Extremum ...

Cone crusher modeling has been subject of much research effort [5], [12]. First principles models may assume one stage of operations or several stages (multizone )or even be continuous involving a partial integrodifferential equation [11]. Others use a empirical .

Advantages Of Using Cone Crusher

Advantage of gyratory crusher in india advantages of using a gyratory crusher over a jaw crusher Advantages and disadvantages of crushers crusher used cone stone crusher for sale in india Get Now Crusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust The earliest crushers were.

Cone Crushers HP Series Cone Crushers

HP cone crushers can be converted from the finest to the coarsest cavity simply by replacing the mantle, bowl liner, adapter ring, and wedge bolts. Easy to operate Using the hydraulic motor setting adjustment with the adjustment under load capability makes it easy to balance

Safety warning over clearing metal tramp blockages in cone ...

May 18, 2020 · SafeWork SA recently issued a safety alert reminding businesses to ensure safe systems of work are in place when using and maintaining crushing plant following a fatal injury when attempting to clear a metal tramp blockage in a cone crusher loed in a quarry. The crusher was not in operation at the time of the incident. The alert said people entering into a cone crusher,

cone crusher, hydraulic cone crusher, symons cone crusher ...

Introduction: Spring cone crusher is suitable to crush all kinds of ores and rocks with medium hardness and above. It has features of reliable structure, efficiency, capacity,low operating cost,easy adjustment,economical to use and so on.

NMS CC800 Cone Crusher Won the Mining Equipment Quality .

Oct 08, 2021 · CC800 cone crusher makes use of laminating crushing principle and adopts full feeding, so crushing force is big, crushing effect is good, reduction ratio is high and capacity is large. Its energy consumption is 15 ~ 30% lower than that of spring cone crusher, and its maintenance is simple.

Crushers and Their Types – IspatGuru

Apr 03, 2015 · A cone crusher is suitable for crushing a variety of midhard and above midhard materials. Feed is dropped to the crusher from the top and it is crushed between the crushing chamber and the slowly rotating cone. Cone crushers are mostly used .

Raptor® Cone Crusher best in class | FLSmidth

Raptor® 900. Our R900 is the smallest of the cone crushers that we designed specifically for mining. It can handle the larger loads, common in the mining industry. This model has many advantages for its size. Large and robust with a rigid fourarm mainframe and integral countershaft. m (70 in) head diameter.

USA

A hydraulic accumulator particularly useful in connection with gyratory crushers of the type in which the crusher head and shaft are hydraulically supported so that when the crusher head encounters uncrushable material such as "tramp iron" the crusher head can move down to pass the tramp iron, causing at least some of the hydraulic fluid supporting the crusher shaft to be ejected to a ...

Rock Crushing Rule of Thumb

· Use jaw crushers for hard materials but shift to cone crushers when hardness Mohs < 8 but not for sticky materials. Jaw crusher: feed diameter to ; reduction ratio 5:1 to 10:1; capacity 1 to 300kg/s; Mohs hardness < 9 [reduction by compression].

USA

A method for determining the adjustment of a crusher gap setting and/or crusher rate of wear in a gyratory crusher with hydraulic adjustment of the crusher cone height. The invention allows measurement of the gap while the machine is in motion and this data permits automatic adjustment during operation.

Tracked Mobile Cone Crushing | | Symons Cone Crusher ...

The cone crusher has standard type and short head type, the standard type is suitable to medium size and the short head type for medium and fine crushing. HP Series Multicylinder Hydraulic Cone Crusher is one of advanced cone crushers in China, which is developed and manufactured by our company. The machine is one kind of highclass product ...

What is a Cone Crusher| Advantages, Types, Parts and ...

Cone Crusher Advantages. Laminated crushing, high crushing efficiency, good shape of the discharged material. Medium and fine crushing cavity type, easy to switch, multipurpose in one machine. Using a multifunctional hydraulic operating system, easy maintenance, improve equipment operation rate.

Latest Posts

- استخدام بيع معدات تعدين الذهب

- تكلفة آلات الطحن الصغيرة

- محطات توليد الطاقة بالفحم الصين

- مطحنة الكرة في التعدين كارارا

- الإمدادات والمعدات اللازمة للتعدين خام الحديد

- الكسارات الفك للبيع في كوريا الجنوبية

- طحن آلة الصانع في ولاية غوجارات

- عملية سيانيد الصوديوم للذهب

- آلة تكسير الفحم المتنقلة متعددة المراحل للبيع

- تستخدم كسارة مخروط الذهب الخام الموردين السعودية

- أسعار آلة كسارة تغلي في الأردن

- آلة كسارة الحجر في كندا

- الكسارات مخروط المملكة العربية السعودية

- خط سحق خام الحديد الألغام

- خلع الملابس حزام ناقل

- What Is A Vertically Integrated Mill With Examples

- Granite And Marble Machines

- Iron Mining With Surface Miner

- Stone Crushers Working Methodology Pakistan

- Indonesia Grinding Mill

- Crusher Run In Matang Pagar

- Sand Cement Block Maker In South Africa

- Platinum Mining To Private Companys In Vanuatu

- Mile Elm Sand Quarry Jamaica Crushing

- Brick Making Machine For Sale Uk

- Pe 250 400 Stone Jaw Crusher Crushing Plant With Spare Parts

- Brass Scrap Crusher For Crushing In United Kingdom

- Specific Gravity Of Limestone Rock

- Silica Sand Suppliers In Chennai

- Jun 15 Gold Mining Equipment Catalog