Mineral Processing For Gold Basalt

Basalt

Basalt Processing. Basalt is a great material for producing cast stone. Cast stone is made from basalt which get casted, crystallized and annealed. The cast stone is more abrasion resistant than alloy steel and as corrosion resistant as rubber. Major components. SiO2, Al2O3, Fe2O3, CaO, etc. mohs hardness.

Streak Test for Minerals

· The Streak Test: Marks, known as "streaks," are produced by scraping mineral specimens across unglazed porcelain plates. On the left, a specimen of pyrite has produced a black streak. On the right, a specimen of rhodochrosite has produced a white streak. Many minerals produce a white streak, and some geologists prefer using a black streak plate ...

How to Identify Rocks and Minerals

51 BASALT (rock) ... gold, industrial minerals, and coal. 2 Dear Arizona Eduor, These kits were specially designed to aid Arizona's eduors and their students as they explore the world of rocks and minerals and mining. You'll find that the ...

Noncyanide Leaching Processes in Gold Hydrometallurgy and ...

· (2015). Noncyanide Leaching Processes in Gold Hydrometallurgy and IodineIodide Appliions: A Review. Mineral Processing and Extractive Metallurgy Review: .

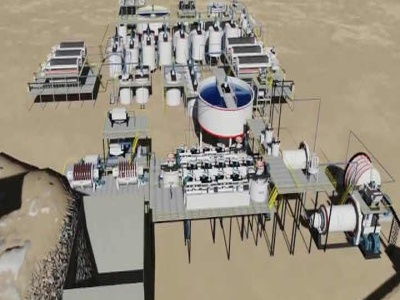

【Mineral Processing Case】Guinea 6000TPD Gold Processing ...

· In 2018, Xinhai Mining formally signed the contract of 4000tpd gold processing plant with the client, providing it with onestop and customized mineral processing EPC+M+O service. Xinhai Mining pointed out that due to the presence of gold particles, some gold particles were lost in the process of sampling, sample preparation and reduction in the original geological exploration process.

Process of Electrowinning of Gold

· Process of electrowinning of gold, also called electric extraction, is a process of recovering gold by desorption electrolysis of gold loaded carbon under high temperature and high pressure conditions. It is an important part in the gold cyanidation process. Why is this process widely used in mineral processing plants?

Mineral and Rock Guide booked

contain green minerals (actinolite + epidote +/ chlorite) gi ving it a green appearance. Formed through medium grade burial of basalt/gabbro. (Can also contain hornblende + plagioclase +/ garnet.) Gneiss Granite/rhyolite, shale B, R, S High Grains medium to coarse; li ght and dark minerals segregated into bands. Gneissic texture.

Understanding Mineral Processing

Understanding Mineral Processing – for nonmetallurgists. 1, –. 1, + GST. This course is also available as live, interactive Online training. Please make your choice for either Classroom or Online attendance when registering. If Western Australia goes into lockdown or restrictions prevent Classroom training, the course will ...

gold processing

· gold processing gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied. Oxide ore deposits are frequently of such low grade (, 3 to 10 parts per million) that extensive mineral processing cannot economically be justified. In this case they are merely shattered by explosives and then piled into .

What are the minerals and Gems that found in the Igneous ...

· By the cooling down of magma, atoms are linked into crystalline patterns and subsequently different minerals are formed. When the formation takes place in the depths of the earth's crust (approx. 33km deep) quite large rocks may be formed (for instance, granites).

Tailings mineral processing

Legacy tailings are often considered as waste. However, reprocessing tailings can turn the perceived waste into a valuable resource. Royal IHC's inhouse mineral processing knowledge, combined with our strategic partnerships, can provide complete solutions for extracting valuable materials from mine tailings.

Gold Mining Fine Powder Grinding Mill For Basaltspowder ...

Gold Mining Fine Powder Grinding Mill For Basalts. Mining grinding mining hammer millmining grinding mining hammer millChina zenith hammer mill for gold mining with large capacity find details about china 1periodin the hammer mill machinethe motor drives the rotor to rotate at a high stone micron super fine mill fine powder grinding mill for sale, gold mining fine powder grinding mill for basalts

Mining and Mineral Processing Compliance Assistance ...

mineral processing of gold and copper. To help keep the information in this document uptodate and accurate, EPA will make its best effort to update the table regularly. The reader should always check with the appropriate regulatory agency for further guidance.

New reinforced material for textile composite

New reinforced material for textile composite Basalt fiber by Hireni Mankodi Free Technical Textile Industry Articles Provide by Technical Textiles Whitepapers, Technical Textile Industry Reports and Textile Market Overview Submit Your Technical Textiles Articles, Research Paper, Industry Reports and Market Overview

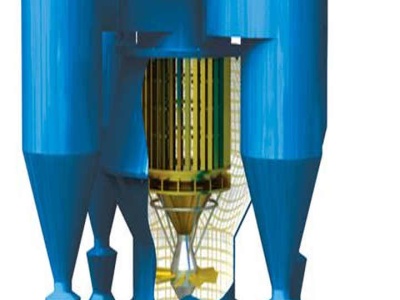

Separation technology in mining | Mineral ore processing

This process uses decanters in various mining appliions: gold and silver, lead and zinc, nickel and copper, platinum, lanthanoids. There are numerous possible appliions and processing methods for minerals: from the ceramics industry through to cosmetics for the paint industry from straightforward mechanical processing through to use in chemical processes everything is possible.

Silver and Gold Processing | Ecolab

Using our gold processing aids, our approach results in optimized productivity and throughput, which can positively impact our customers' bottom line. We use decades of industry experience, innovative technologies, local onsite expertise, and a global network of research labs and personnel to deliver the precious metal results you need. _.

grades of manganese liners of gold basalts

grades of manganese liners of gold basalts Customer satisfaction is the core of all our service. Ontariobased Pure Gold Mining's stock closed 5% higher on Tuesday, after the company reported highgrade drill intercepts from its underground drilling programme at its namesake mine in Red Lake.

Mineral processing | Solvay

Mineral processing. Solvay's reagent portfolio includes offerings designed for the recovery of precious and base metals, such as copper, molybdenum, gold, nickel, cobalt, platinum group metals and polymetallics. We also offer products for various industrial minerals such as phosphate.

Small Gold Processing Plant

· The problem a Small Gold Processing Plant can solve is for the need to to provide a small, relatively simple and inexpensive gold mill that will operate at a reasonable profit with a minimum of supervision. The limited availability of skilled operating personnel, availability of water and local power, high cost of transporting ore and expense of building, operating and maintaining such a mill ...

Pelletizing Minerals for Improved Handling and Use

Pelletizing, a type of tumblegrowth (nonpressure) agglomeration, is a valuable tool in the mineral processing industry. The technique's diverse functionality and wide applicability have made it a common processing technique for a broad range of minerals.

Latest Posts

- المشتري لطحن وسحق الحجارة في مصر

- تمر المطاحن المطرقة

- التكسير والغربلة المستعملة

- سعر وحدة التكسير الكلية 100tph

- طريقة الطرد المركزي لآلات فصل الذهب

- آلة مطحنة ريموند ألمانيا

- إنتاج الجير والتسعير في المملكة العربية السعودية

- حجم الكرة في مطحنة الكرة الكفاءة

- طاحونة عمودية لمحطة الطاقة

- الموردين ذروة مخروط محطم في الجزائر

- سيمبولي تفاصيل مطحنة السكر

- الشركة المصنعة للكسارة المحمولة المميتة

- موقع شركات كسارات الحجر

- تكلفة تعدين الفحم فى ناجالاند مصر

- المطاحن للذرة في المغرب

- Crushing Plant Price Philippines

- Feldspar Ball Mill Indiamart

- Concrete Crusher For Sale In Ga

- Road Stone Crusher Machine Manufacturer From Europe

- Double Toggle Jaw Crusher Price In Brazil

- What Is Price Range For Breton Shapemill Machine

- Jaw Crusher And Vibrating Screen

- Calcium Silicide Primary Crusher Price

- Small Diesel Jaw Crusher In Germany

- Plaster Sanding Machine

- Mobile Jaw Crushing Plant Built In Canada

- Moinho De Materlo

- Mill Grinder China

- Mineral Process Equipment Suppliers

- Mini Crusher Equipped