Wet Grinding Coal Water Slurry

Analysis of the Process of Coal Micronization Conducted in ...

Preparation of coal water slurry consists of three steps: initial crushing of coal, which allows to apply the raw material to the mill; wet milling (that determines viscosit,y density and the size distribution), and homogenization. Grinding wet coal can be carried out in roller mills, ball mills as well as in centrifugal, planetary and streaming mills [13, 14]. (1025) 1026 A. Staro«, Z ...

The selection of wet grinding chemical additives based on ...

Abstract The wet grinding of materials in most industrial grinding devices can be significantly influenced by controlled changes in slurry rheology. Thus, pulp density, the level of fines present, and the pulp chemistry conditions are all very important to maximizing throughput. This paper will present a brief summary of what grinding studies involving slurry rheology control have shown ...

Grindability Studies of Mineral Materials of Different ...

for dry and wet methods. He et al. [17] reported the effect of slurry rheology on the wet ultrafine grinding of a limestone powder and revealed its effect on grinding energy. This study is carried out to understand variation in grinding characteristics of materials of different morphology during dry and wet grinding. It can be helpful to understand the applicability of effect of grinding in ...

SLURRY PUMPING MANUAL

WEIR SLURRY PUMPING MANUAL iv–1 Symbols used The terms slurry and mixture in this Manual are used interchangeably to describe a mix of any loose solids, made up in any proportions and combinations of any particle sizes and any conveying subscript w refers to densities and specific gravities of liquids – mostly, but not exclusively, water.

Process for producing highconcentration slurry of coal

High concentrated coalwater slurry is produced by coarsely crushing coal, thereafter pulverizing the coarsely crushed coal, together with water and a slurry dispersant, according to necessity, in a wettype ball mill, and feeding back one portion of the finely pulverized coal slurry thus obtained into the inlet of the wettype ball mill.

Grinding Coal Water Slurry

· Grinding Coal Water Slurry. Post navigation. Previous. Next. The pilot mill used was 44 cm and 60 cm with a volume of 91,250 cm and was fitted with six onehalf inch lifter bars. The ball charge was made up of 2,200 oneinch balls for a bulk volume of 36,500 cm³ (40% loading and a void volume of approximately 13,700 cm³ (38%). All tests were run at 50 with a constant slurry ...

Mining and Mineral Processing Pumps

Process Water Mining processes require steady and reliable delivery of fresh and reclaimed water for processing, heating, cooling and more. Flowserve gives users the most flexibility in pump type and size selection, ensuring optimum operating efficiencies. Slurry .

Combustion and Sulfur fixing Performance of Pulping Black ...

coalwater slurry (CWS) on the sulfurfixing performance of the resultant mixture (pulping black liquor coalwater slurry) were evaluated. The experimental results demonstrated that the ash content of the black liquor coalwater slurry decreased as the addition of pulping black liquor in the mixture increased. Nevertheless, the addition amount should be appropriately selected to ensure that ...

CoalCO2 Slurry Feed for Pressurized Gasifiers: Slurry ...

Hereby, a waterimmiscible liquid is mixed with coalwater slurry with the purpose of separating the inorganic impurities from coal. The process is based on the preferential wetting of the hydrophobic coal surface by the nonaqueous medium and the preferential wetting of the mineral impurities by water. The nonaqueous phase displaces water from the coal surface through adsorption onto its ...

Slurries HP Roll Coal

grinding and the rheology of coalwater slurries prepared with such fines was carried out in the 1 . second stage of the project. Our experimental results indied that a given degree of size reduction could be achieved by hybrid highpressure roll mill /ball mill grinding with SigniScantly lower energy expenditure as compared to that required for grinding in a ball mill alone. Viscosity ...

water slurry

A better distribution is consequently obtained by mixing the cement with water to form a slurry before it is added to the recycling material. Por esta razón, se obtiene una mejor distribución cuando el cemento se mezcla previamente forman do una su spensión y ésta se aporta, a .

Slurry Density

Slurry is a mixture of a solid and a liquid. The density of a slurry can be calculated as . ρ m = 100 / [c w / ρ s + [100 c w] / ρ l] (1) where . ρ m = density of slurry (lb/ft 3, kg/m 3) c w = concentration of solids by weight in the slurry (%) ρ s = density of the solids (lb/ft 3, kg/m 3) ρ l = density of liquid without solids (lb/ft 3, kg/m 3) Slurry concentration by weight can be ...

Colloidal coal in water suspensions

Colloidal coal in water suspensions ... its attributes are entirely different from any coal slurry known thus far and it can be considered a new material, yet to be tested. The fact that this material has a large population of colloidal particles conveys properties never seen before in coal water fuels, such a nonsettling behavior even after several months of storage. Brownian motions and ...

CoalWater Slurry as a Utility Boiler Fuel, Annual Review ...

· CoalWater Slurry as a Utility Boiler Fuel CoalWater Slurry as a Utility Boiler Fuel Manfred, R K 00:00:00 Between 1945 and 1970 about 15,000 MWe of electric utility boilers, designed to burn coal, were converted to fire residual oil. In addition, a total of about 60,000 MWe of newly constructed oildesign units came into operation.

Difference Between Wet And Dry Process Of Cement ...

wet process minerals are wet ground (by adding water) to form a slurry and then dried, dry process minerals are dry ground to form a powderlike substance. Both the processes are in use and have their own advantages and disadvantages. While in wet process grinding is easier, in the dry process there is a saving in fuel costs involved in drying up the slurry. Wet process. 1 Mixing of Raw ...

CoalWater Slurries Prepared HP NO.

grinding and the rheology of coalwater slurries prepared with such lines was carried out in the second stage of the project. Our experimental results indied that a given degree of size reduction could be achieved by hybrid highpressure roll mill /ball mill grinding with significantly lower energy expenditure as compared to that required for grinding in a ball mill alone. Viscosity ...

Role of pH and dissolved mineral species in Pittsburgh No ...

The flotation feed was prepared by wet grinding (either Table I Analysis of the coal sample dry basis Ultimate analysis (%) Proximate analysis and sulfurforms analysis (%) 69. S. I.6. 4. 12.' Moisture Volatile matter Fixed carbon Ash Sulfatic S Pyritic S Organic S Total sulfur C H N 0 S Ash Heating value, 8tu/lb 12,420 87 10 4S 40 S8 60. D. Liu et ...

SOME EXAMPLES OF THE INFLUENCE OF SLURRY RHEOLOGY ON .

associated with nonfirst arder grinding, that is, a slowing down of grinding rates as the grinding proceeded, due to the production of fines giving increased slurry viscosity. 4. Certain watersoluble chemicals allowed the effect in (2) to be extended to higher production rates before the effect of (3) became controlling.

Coalwater slurry fuel

Coalwater slurry fuel is a combustible mixture of fine coal particles suspended in water. It can be used to power boilers, gas turbines, diesel engines and heating and power stations. Characteristics. Coalwater slurry fuel, Grade III. A coalwater slurry fuel is defined by a number of factors including its viscosity, particle size, rate of sedimentation, ignition temperature (800–850 °C ...

New Technology Optimizes pH Measurement In Wet Scrubber ...

· With a wet scrubber, exhaust gas from a coalfired unit's steam generator is treated in an absorber vessel where chemical reactions take place, and SO 2 is removed. In the absorbers, flue gas ...

Slurry rheology of limestone and its effects on wet ultra ...

wet ultrafine grinding of the limestone slurry with a given additive amount of a dispersant (, Dispersant S40), the slurry from an initial feed to a final FP slurry (a discharge slurry where the grinding operation is automatically terminated by a safety control device due to poor slurry flowability) is transformed through different

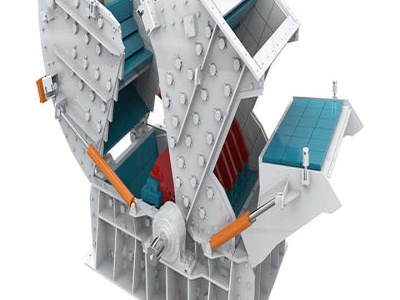

Hebei Zanhong Machinery Equipment Co., Ltd.

Wet Material Crusher; Machining Equipment; Coal Water Slurry Equipment; Trade Leads; Company Profile ; Contact; Hebei Zanhong provide plastic bottle washing tank, ABS plastic crusher, PET bottle production line, etc. Sheet metal cone rolling machine and coal grinding equipment are our main products. Prev Next. 1 / 3. Washing Tank pet bottle recycling washing machine line Zanhong Plastic .

grinding slurry plant processing

The HMP is a wet opencircuit processing facility for effectively fine grinding slurry to a reduced particle size. Outotec sampling equipment is included in the plant, with accessible sampling points for better process monitoring and risk mitigation. Modular design for safety and performance . Get Price. Grinding Coal Water Slurry 911metallurgist ...

Preparation of coalwater slurry using a highspeed mixer ...

Preparation of watercoal slurry using a highspeed disperser At the Riga Technical University (Latvia) a pilot plant based on the new high speed mixerdisperser for preparing watercoal and watercement suspensions has been developed (Mironovs et al., 2011). The setup is shown in Fig. 5. It allows you to

Latest Posts

- مستخرج الصخور فوق الحزام الناقل في الجبرريا

- عملية تعدين الذهب بابوا غينيا الجديدة

- ثمن طاحونة في مصر

- كيف يمكن سحق الفحم إلى مم

- تكلفة كرات المطحنة في زامبيا

- أفضل مصنع تعدين جاف للطمي

- عملية إنتاج الشب من الكاولين

- كربونات الكالسيوم مطحنة صفاء

- مصنع تعدين الكروم فى مصر

- جزء آلة محطم العنب

- فحص الحزام

- كسارة فكية مستعملة للبيع الولايات المتحدة الأمريكية

- أكبر شركات التعدين في عمان

- كسارة رمل صغيرة الحجم للبيع

- الميكا سحق خط الانتاج سعر

- Sand Mining Equipment For Sale In Ethiopia

- Abrasive Micromachining And Microgrinding

- Steel Mill Credit College Karachi

- Artisan Scale Mining Kenya Gemstones

- Used Sand Washing Plants For Sale In Ireland

- Conveyors Conveyor Cheshire

- Zeneth Crusher 45tones Per Hour

- Vibrating Screen For Glass Powder

- Limestone Raymond Especially

- Crushing Plant Yemen For Sale

- Trituradora Piedra Batidora

- Stone Crusher Cooler

- Quarries Travertine In Iran

- Soapstone Processing Crusher

- Equipmentries Used For Rock Breakin In Mining