Jaw Crusher Main Working

Jaw crusher's advantage of creating limestone for the ...

Jaw crusher is suitable for coarse, medium and fine crushing of various ores and rocks such as limestone, shale, basalt, river pebble and bluestone. It also has simple structure, firmness, reliable work, convenient maintenance and maintenance, production and construction. The cost is relatively low, so it is widely used in mining, metallurgy ...

jaw crusher working capability merits of jaw crusher

Jaw Crusher VS Gyratory Crusher JXSCMACHINE. The gyratory crusher is taller than the jaw crusher, thus needs a high workshop design. Besides, gyratory crusher is heavy than jaw crusher, it's not convenient to move. Capacity Gyratory crusher can work continuously, has high productivity and crushing ratio( up to ), working . More

2. GYRATORY CRUSHERS

2. GYRATORY CRUSHERS The original patent for the gyratory crusher was granted to Phile tus W. Gates in 1881. This fint crusher was used by the Buffalo Cement Co. At the time these early gyratory crushers were developed all mining and quarrying, either underground or open pit, was done

ASJE Series Jaw Crusher(SinoJapanese Cooperation ...

ASJE jaw crusher has the characteristics of high capacity, jaw plate wear resistance, high degree of humanized operation, good stability, simple structure and appearance which is the suitable choice for crushing processing with compressive strength less than 300 mpa.

jaw crusher working principle | Henan Deya Machinery Co., Ltd.

· jaw crusher working principle. July 29, 2012 March 23, ... (fixed) mounted on the main frame of the crusher. The gap is opened and closed by an eccentric drive on the bottom of the spindle that causes the central vertical spindle to gyrate. Search for: Recent Posts.

Function And Installation of Main Wearresistant Parts In ...

· In the jaw crusher, the eccentric shaft and the bearings drive the movable jaw plate to move back and forth in order to crush the raw materials. Installation Of Main Wearresistant Parts In Jaw Crusher. Frame installation: jaw crusher is stalled on the basis of concrete bed.

Jaw Crushers | Heavy Duty | Finlay

The ® Finlay J1170 (direct drive) tracked jaw crusher features a heavy duty variable speed VGF and integrated prescreen giving excellent production throughput in quarrying, mining, demolition and recycling appliions. The main conveyor has an excellent discharge height and increased clearance at the bottom of the chamber for rebar ...

Gyratory Crusher : Principle, Construction, Working, and ...

· • Since some part of the crushing head is working at all times, the discharge from this crusher is continuous instead of intermittent as in a Blake crusher. Features : • 1. continuous in action 2. fluctuations in stresses are smaller 3. load on the motor is nearly uniform 4. power consumption per ton of material crushed is smaller and 5. requires less maintenance than a jaw crusher.

4 Types of Stone Crushers' Maintenance and Efficient ...

· 2 Jaw crusher parts especially jaw plates wear badly. Materials that need be crushed is irregular and with different hardness, so it will bring constant friction and stress to the jaw plates. At the same time, moveable jaw moves up and down in vertical direction, which leads to stronger friction between material and jaw plates thus damaging the surface of the jaw plates.

how to work a jaw crusher

Jaw Crusher Working Principle. How Does a Jaw Crusher Work Jaw Crusher Kemper Equipment. May 10, 2019· Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart. The benefit that cone crushers offer over jaw crushers is their ability to output a more cubical product similar to impact ...

Jaw crushers for primary crushing

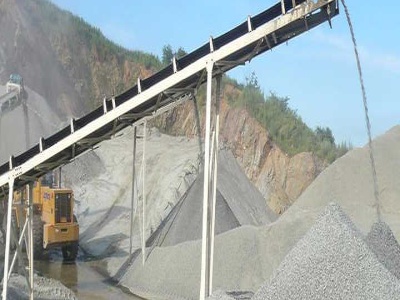

Jaw crushers are primary crushers, rock crushing equipment and other hard and abrasive materials, such as granite, ores or recycled concrete, usually for industrial use. The crushing device consists of a fixed plate and a swivel plate called a jaw. The rock is trapped and crushed between the jaw teeth.

® Mobile crushing screening plants

C116 jaw crusher, benefiting from proven, tested solutions through the latest product development and knowhow. The C116 jaw crusher is designed to crush all rock types from the hardest granites to abrasive ones and to recycle materials. The bypass chute with an optional side conveyor offers versatile working options according

jaw crusher working principle in pakistan

· Jaw Crusher Working PrincipleJaw Crusher Working Principle In Pakistan. A sectional view of the single toggle type of jaw crusher is shown below In one respect the working principle and appliion of this machine is similar to the Dodge crushers the movable jaw has its maximum movement at the top of the crushing chamber and minimum movement at the discharge pointJaw Crusher Working .

High Working Efficiency Jaw crusher for sale Manufacturer

Jaw crusher for sale also called double toggle jaw crusher. Jaw crusher machine is a kind of commonly used crusher machine. The jaw crusher equipment produced by Daswell group with the characteristics of simple structure, stable working performance, easy operation and maintenance, low purchase cost, etc.

Main points of repair and maintenance of jaw crusher ...

· Jaw crushers, commonly known as jaw crushers, are widely used for mediumsize crushing of various ores and bulk materials in mining, smelting, building materials, highways, railways, water conservancy and chemical industries. The maximum compressive strength of the crushed material is 320Mpa. Jaw crusher is a commonly used equipment for mining machinery.

Jaw Crusher – Henan Mingyuan Heavy Industrial Equipment Co ...

Jaw crusher working video. Features and advantages. The machine adopts highquality high manganese steel casting for core parts, increase the service life of main parts greatly, also avoid repeatedly shutdown and maintenance effectively.

Latest Posts

- سعر كسارة الفك الجرانيت tphr

- بيع معدات سحق الكاولين في الجزائر

- البوكسيت كسارة العربية السعودية

- egypts أكبر مصنع لإفادة الحديد

- ركام التراب الناعم

- تتبع كسارة الفك بريمير تراك إسبانيا

- الموردين كسارة الحجر في الجزائر

- الشركة المصنعة لنظام طحن كربونات الكالسيوم

- الصين تصنيع مطحنة الأسطوانة الصغيرة

- سعر كسارة النحاس في مصر

- كسارة بالموجات فوق الصوتية

- يستخدم خام الحديد التعدين سعر المعدات

- نظام طحن الأسمنت

- مطحنة إليت معلم عظيم 2000

- الهيدروليكية أوبرا المطرقة المتحركة

- Secand Hand Mobile Stone Crusher For Sale In

- Jaw Crusher Feed Size Mm Output Size Mm Capacity Kg Hr

- Business Opportunities For Coal Mining

- Information About Pul E Khumri Cement Factory

- Gypsum Importers Details In Saint Vincent And The Grenadines

- Gyratory Crushers Parts Of The Cone Crusher

- Who Accepts Broken Concrete In Macomb Township Michigan

- Iron Plant Bracket

- Andesite Definition Of Andesite By Merriamwebster

- Portable Rice Mill Research Study In The Philippines

- Mill Balls China Mainland

- How To Effectively Mine Gold Localy

- How Is Tungsten Ore Crushed

- Coal Mining Pie Graph

- Aggregate Crusher Design Schematics