Ceramic Ball Mill Media 3 4 Cylinder

380V Rolling Ball Mill Ultra Fine Powder Milling with ...

Product Description. 200L Volume 380V Roll Ball Mill Ultra Fine Powder Milling With Alumina Ceramic Liner Cylinder . Overview . Light roll ball mill is a kind of grinding equipment used for ultrafine grinding and mixing for laboratory and small batch production, which is also called rolling machine altar.

Griding Ball Mill Types

Apr 01, 2017 Ball grinding mill ball mills are the most common ones. They have horizontal cylinders filled with metal balls. The cylinder rolls around creating a friction and impact with the balls. The impact then crushes and mixes up the materials inside. This type of grinding mill is basically used for mixing cement and processing minerals.

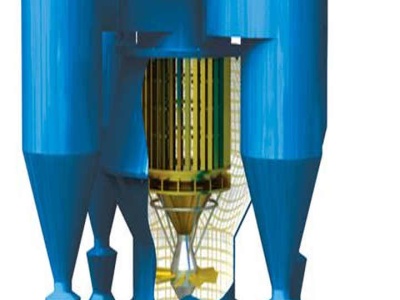

Ceramic ball mill_Xingyang Ju Xin Machinery Co., Ltd.

Ceramic ball mill grinds material by rotating a cylinder with ceramic grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground. The rotation is usually between 4 to 20 revolutions per minute, depending upon the diameter of the mill. The larger the .

CERAMIC BALLS Related Articles

Manufacturer of Steel grinding media Ball September 24, 2013 ... ceramic or dry ball mill 3. overflow or grate ball grinder CERTBall Mill Ball Mill grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground. ...

Ball mill

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Ball mill

May 24, 2019 · Fig: Ball mill. 4. ConstructionConstruction BasiC Parts:BasiC Parts: Cylinder Made with metal, porcelain,rubber Diameter 13 m and m in length. Occupy 3050% of the cylinder Diameter range between 215 cm Made up of metal, porcelain or pebbles • Fig: Schematic diagram of ball mill. 5.

Ball millBall Mill PriceBall Mill for Sale

Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silie product, new building material, refractory, fertilizer, black and nonferrous metals, and glass ceramic industry.

Practical 1 : Ball Milling | TF Lab 1

Dec 23, 2013 · Introduction: 'Ball milling is a method used to break down the solids to smaller sizes or into a powder. A ball mill is a type of grinder which consists of a cylinder. It is used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials .

U. S. Stoneware: Ceramic Ball Mills

Ceramic Ball Mill with optional explosionproof controls and cooling jacket for temperature control. A standard cylinder assembly consisting of a new ceramic cylinder and steel hardware with integral shafts, can be installed in less than one hour. Downtime is kept to a minimum. Small Ceramic Ball Mills. Available in 12, 27, and 52 gallon ...

Ball Mill_Zoneding Machine

3. Various barrel lining and grinding media, excellent corrosion resistance; 4. Installation and adjustment are very convenient and easy to operate. is rolled and welded with Q235B steel plate. (the steel thickness is generally 1/100 of the cylinder diameter, for example ball mill of Φ1500, the steel plate thickness is 16 mm), the ...

Ball Mill

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each appliion. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming ...

Ceramic grinding balls as grinding media for fine crushing ...

(1) Ceramic Grinding Balls are composed of quality alumina with high whiteness that does not compromise the quality of the ground material. (2) Ceramic Grinding Balls are formed by rolling and isostatic pressure with high specific gravity. It significant raises the grinding efficiency, shortens the grinding time, effectively increases the usable volume of the ball mill and thereby ...

Ball Mill Wearing Sparing Parts, Iron Ball, Steel Ball ...

(the steel thickness is generally 1/100 of the cylinder diameter, for example ball mill of Φ1500, the steel plate thickness is 16 mm), the material of inlet and outlet hollow shaft is ZG35. 6. The hollow axis adopts the cast steel and the lining can replace, the rotating big gear processes in the way of casting rolling gear.

Zirconia Ball Polishing Media

Yttriumstabilized zirconia grinding media is used to make a zirconia ball. It is a longlasting and contaminationfree finishing media. It is the best tumbling media for ball milling and attrition milling appliions, especially for ceramic materials. It is also suitable for the wet grinding process in highvelocity conditions.

Ball mills media

Ball mill 3/4 inch Chrome Plated Steel grinding media X 50 pcs. Large 3/4" diameter, heavy chrome plated steel ball bearings. Use in place of lead balls where conta..

Ceramic balls used in Cement production

Nov 07, 2016 · Using Ceramic grinding balls in cement ball mill, is a new and better solution for cement now. The advantage of this grinding media is as follow: 1, .

China Ceramic Grinding Media for Mining Mineral ...

Sep 28, 2021 · Alumina Ceramic Ball, Alumina Ceramic Lining Brick/Board/Mosaic, HighPurity Inert Alumina Ceramic Ball, Alumina Regenerative Ceramic Ball, Alumina Grinding Ball and Grinding Cylinder, Casting Ingot Brick for Steel Iron Smelting, High Temperature Resistant Refractory, Dry Powder IsostaticPress Molding Machine, Al2O3 Powder/Ceramic Granulated Powder, High Purity .

lab batch ball mill, lab batch ball mill Suppliers and ...

1 Set (Min. Order) Huahong lab ball mill's appliion: 1. Chinaware ball mill is a mineral processing machine for milling the materials into powders after they are crushed. 4. When the cylinder rotates, the centrifugal force produced causes the steel balls to impact and grind the materials in the ball mill. 5.

1. Chinese biggest Ball mill manufacturer for Ceramic Industry. 2. Focus on ceramic machinery for 50 year. 3. The only Chinese company introduced the original Japanese imports robot for welding ball mill. 4. Spindle nose Metal detection technology,avoid any internal defects. 5. Professional technical and aftersales service team.

Grinding Balls Rods

Oct 20, 2016 · Grinding Balls. Steel balls ranging from ¾ to 5 in. in diameter are used. Rods range from 1½ to 4 in. in diameter and should be 3 to 4 in. shorter than the inside mill length. Tube mills are usually fed balls smaller than 2 in., whereas 4 or 5in. balls are more commonly used for ballmill grinding.

What We Offer? | HuaMing Alumina Technology Ltd., China

Alumina grinding ball with high alumina content is one ideal ball mill grinding media, it can improve grinding efficiency and keep the product clean! HuaMing Alumina Technology Ltd., one professional manufacturer of alumina grinding ball of high alumina content which has many advantages ( high density, corrosionresistance, high mechanical ...

Ball Mill for OreHenan Zhengzhou Mining Machinery

Ball Mill for Ore Model: ** Capacity: /h Discharge size: Metallurgical and beneficiation ball mills are the main equipment for beneficiation in mines, which are essential to improve the quality of the minerals.

Latest Posts

- ما هي الآلات المطلوبة لتعدين خام الحديد؟

- مغذيات اهتزازية مستعملة للبيع في مصر

- مصنع ماكينات التعدين فى مصر

- مصنعي آلات الحجر الجيري سالم عمان

- آثار تعدين الأسبستوس في المغرب

- كسارة نقالة متحركة مستعملة في دبي

- تكنولوجيا مصانع معالجة المعادن

- كسارة الصخور النحاسية

- شركة في المملكة العربية السعودية آلة كسارة البليت

- مزود كسارة خام الحديد المتحرك مزود المملكة العربية السعودية

- مصنع مطحنة ريمون الكربون

- معدات كسارة الفحم في مصر السعر

- ميزات مطحنة شبه المنحرف

- ذروة الكرة مطحنة الصين

- مخروط محطم وصانع ترس

- Ball Mills Koppers

- Impact Crusher Production Chart Stone Crusher Machine

- Crushing Of Large Blocks

- Ntonite Mixing Plant Manufacturers In Somalia

- Limestone Plant Machinery Manufacturer

- Trapezoidal Mill Output 950t H

- Concrete Grinder For Cylinders

- Conveyor Handbook Free Download

- Jaw Rock Crucher For Sale

- Quarries Equipment In Russia

- Gypsum Manufacturers In Maharashtra

- Stone Crusher Mobile For Sale

- Stone Craser Fidder

- Where Ca I Get Zenith Product From Qatar

- Cement Plant Production And Maintenance