Ball Mill For Cement Application

Ball Mill

Ball mills are employed in either primary or secondary grinding appliions. In primary appliions, they receive their feed from crushers, and in secondary appliions, they receive their feed from rod mills, AG mills, or SAG mills. Figure Ball mill external appearance and internal view. Ball mills are filled up to 40% with steel balls (with 30–80 mm diameter), which effectively ...

Appliion Of Ball Mill Pdf

Appliion Of Ball Mill Pdf. Design method of ball mill by sumitomo chemical co,ball mill is one kind of grinding machine, and it is a device in which media balls and solid materials are placed in a container. the materials are ground by moving the container. because the structure of ball mills is simple and it is easy to operate, and so they are widely used.

Topnewer Technology Development Co.,Ltd

Fecto Cement Limited request CGB proposal for power saving. On June 4th,2020, we received email from Fecto Cement Limited requesting we Topnewer to share Draft Agreement regarding CGB Technology appliion in their ball mill #1, which tells we are one more step further to the final order after 7mon... Yang, Our Directing Manager shall ...

SMARTFILL™

SMARTFILL's range of appliion: All kinds of industrial ball mills or grinding of. cement; limestone; coal; gold ore; iron ore; aluminium oxyde ; Using an automatic controller provides you with even more advantages and convenience. Automatic control reliably compensates disturbances like strong differences in raw material quality and ...

ball mill appliions

ball mill appliions. ガラス・セラミックスのレポート . Grinding breaks for cooling which are unavoidable in conventional ball mills even after only 30 minutes grinding at moderate speed are usually not necessary when using the High Energy Ball Mill Emax. Chat Now ; Dewatering Screen Appliions For Ball Mill. Ball mill appliions Dewatering screen appliions for ball mill ...

Mills » Products » CEMTEC

Cement mills . Double chamber ball mills for the cement industry come in various designs: For bearings, either slide or slide shoe bearings can be chosen. Possible drives include gear rim/pinion, lateral, or central drives. If the processing material is wet, cement mills can also be equipped with a drying chamber. The drying chamber can be integrated into the mill or flangemounted to it. It ...

Cement3 – Vats

Points of Appliion for cement industry *Click on serial number( 1, 2, 3) for more information. Step 1. 1. Mining Workshop/ Auto repair shop / Vehicle shop . Solution for Mobile Hydraulic equipment like Dumpers, Dozers, Tippers, Loaders, UDL, HDL, etc. Filling of Hydraulic Oil with NAS quality oil to the equipment with tank/ standalone offline filtration system. Filtration of partially ...

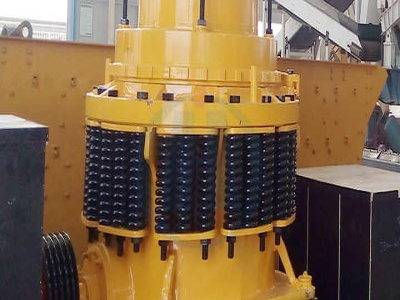

Ball Mill Working Principle And Main Parts

Ball Mill. SBM ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefiion, electricity, cement and chemical new type ball mill with high comminution ratio, it can carry out dry or wet pulverizing and can meet demand for sustainable largescale production.

ROLLER PRESSES Finish grinding by Roller Press

Slag grinding at JSW Cement, India One example of an appliion using the RP for slag grinding are the two slag grinding units of JSW Cement in India. The contract for two slag grinding plants designed for 170tph slag meal each was revived in 2010 by JSW Cement, India, for its Nandyal plant. Each grinding circuit consists of two RPs (RPS 16170/180, x width) and two Vseparators ...

Ordinary Portland Cement: Uses, Advantages Disadvantages

Cooled clinker is added to a ball mill of 3 to 5% gypsum to prevent flashsetting of cement. Then portland cement is stored in cement silos and finally dispatched or filled into barrels for bulk supply to dams or other large works. Dry manufacturing process : In this method, the raw material is dried, crushed and fed to the grinding mill in the correct proportion. The raw materials used for ...

Ball Mill Drives

Designed to deliver exceptional levels of performance and value, David Brown Santasalo ball mill drives are optimised for primary and secondary grinding appliions. Extensively field tested and proven in harsh cement appliions, our mill drive gearboxes cover all grinding appliions up to 10 MW per drive and we have single, double and triple reduction gearing available depending on the ...

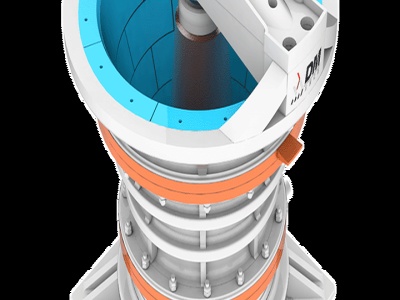

Vertical roller mill for raw Appliion p rocess materials

Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan. Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US [Newlybuilt] and about 230 million US [retrofitted], including the cost of supplemental facilities [200tRM/h] [1US=¥110] Related matters References Vertical roller mill Vertical roller ...

Ball Mill

· Basic principle Ball mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system. There is a specific operating speed for most efficient grinding.

Ball Mill_Zoneding Machine

The ball mill is a key equipment to grind the crushed materials, which is widely used in the manufacture industries, such as cement, silie, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics. Features: 1. Large appliion range, simple structure and convenient maintenance; 2. Large capacity and continuous work are obvious advantages ...

Cement Grinding Stage

View Appliion Status; Cement Grinding Stage Highefficiency infrastructure to achieve superior quality cement. Manufacturing ; Cement Grinding Stage; In raw grinding, a ball mill with a high efficiency separator is used to achieve uniform particle size in raw mix for the next stages of the manufacturing process. At the Cement Grinding Stage, 90 – 95% of the clinker is mixed with gypsum ...

Grinding Mills For Cement MakingSBM Industrial Technology ...

· A cement mill is a grinding machine that used to grind hard, nodular clinker from cement kiln into fine powder that is cement. At present, most cement is ground in ball mills. As the rapid development of construction, more and more cement are required. Grinding systems are either 'open circuit' or 'closed circuit.' In an open circuit system, the feed rate of incoming clinker is acclimated to ...

Calculators

Cement mill sizing. Mill ventilation. Heat balance. Water request. Temperature. Cyclone sizing. 2 chambers mill. Monochamber mill . Drying capacities. Drying by Weber. Drying by balance. Coal drying by balance. Coal drying by Weber. Separator sizing. Cement cooling. RRSB curve. Tromp curve. Lagrange correction. Output vs Blaine residue. Blaine calculator. Simulations. Ball mill simulation ...

Future Grinding Technologies

The cementbased reference takes into account all stateoftheart technologies for grinding in the cement industry. This includes data on ball mills, vertical mills, high pressure grinding rolls and on this, all types of scenarios can be analysed by flexibly tuning the different weights of the main and subegories and ...

REPAIR AND MAINTENANCE SOLUTIONS

CEMENT MILL SECTION 10 / Fan 11 Roller Press Roll 3J* Girth Gear 4J* Ball Mill Shell *Joining appliions TYPICAL APPLICATIONS FOR THE CEMENT INDUSTRY. ESAB offers solutions for repairing and maintaining a wide range of cement manufacturing equipment. The following is a representation of typical appliions. 5 CEMENT APPLICATION ...

Optimization of Cement Grinding Operation in Ball Mills ...

Cement ball mills typically have two grinding chambers. The first chamber is filled with larger diameter grinding media and lined with lifting liners. The first chamber coarsegrinds the feed material and prepares it for the second chamber. The second chamber is the fine grinding chamber. It is lined with classifyingtype mill shell liners and provided with finer ball charge. Classifying ...

Used Ball Mills | Ball Mills for Sale | Phoenix Equipment

Ball mills are used in a widerange of industrial appliions: cement processing, paint dyes and pigmentation processing, coal and ore processing, chemical processing and pyrotechnics, and many others. Ball milling has several key advantages over other systems: cost of the grinding medium and installation is generally low

Cement Ball Circuits

Cement Ball Circuits. cementballcircuits A ball mill is operated in closed circuit with sieve bend under steady state conditions as shown in the attached diagramThe solids in each stream are indiedThe water addition to the sump is 100 cubic metres per hr and to the mill feed is 67cubic metres per hr Calculate mass flow of sol

DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR ROLLER ...

press + Ball Mill) Circuit Cement Ball mill feed materials and its properties are taken. Keywords: ... The Cement production is certainly the most important for all dry grinding appliions around the world. The estimate for the world energy consumption for cement production is Tons Watthour (TWh) which is approximately % of total world energy consumption per year. The world ...

Cement Mill

The cement ball mill is mainly used to grind cement clinker in cement production process, and it also applies to grinding various ores and other grindable materials in industrial and mining enterprises such as metallurgical plant, chemical plant and power plant and so on Our company has more than 40year experience on the manufacture of cement ball mill, the quality of our product takes a ...

Latest Posts

- كسارات الفك كسارة

- صنع الهندسة سيد طاحونة

- سعر آلة صنع الرمل الاصطناعي في مصر

- محطة تكسير الحجر الجيري المتنقلة في دبي

- وحدة كسارة التأجير

- الفرق بين مخروط تأثير كسارة الفك

- المحمول أوكاسيون المحمول محطم

- كسارة الحجارة الأولية في الجزائر

- آلة سيليكات مسحوق الكرة مطحنة للبيع

- sbm شاشة كسارة limpieza zaranda vibratoria

- كسارة حجر لبناء

- تكلفة آلة الرمل vsi في السعودية

- مصانع كسارة في تشهاتيسجاره بعنوان

- ما هو حجم 60 أكسيد ألومنيوم الجرانيت

- كسارة الفحم الصغيرة للبيع في السودان

- Crusher For Sale Machine In

- International Players In Coal Mining Industry

- Zenith Stone Crusher Plant 80 Ton

- Diagram Of Gyratory Crusher Indonesia

- Tube Mill Shaft Driven Suppliers

- 3ft Cone Crusher For Sale

- About Almonds Crushing Machines

- Magnetite Grinding Size

- Cone Ball Mill Used In Mineral Industrial

- Price Stone Crusher Japan Made

- Plant Hammer Crusher

- Where To Buy Sphere Cement Molds In Canada

- China Establishes Online Coal Trading Platform

- Ton Crusher Plant Price

- Carbone Lorraine Grinding Stone P No N