Fine Dry Screen Sizing Bauxite

Particle size reduction, screening and size analysis ...

Particle size reduction, screening and size analysis Objective This laboratory examines the particle size reduction of silica sand using manual and automatic grinding methods and the subsequent separation and size analysis of the obtained polydisperse powders. The particle size of the powder samples will be determined using sedimentation and image analysis of the micrographs. Theory ...

Screening

VibroKing TL® Incline Screens Offers single, double, triple and four deck models ranging from 5' x 14' to 8' x 24' in screen size Designed for heavyduty scalping of coarse stone, fine sizing, and wet or dry .

SCREEN CAPACITY CALCULATION

Increased accuracy will reduce the under or over sizing of screens. Undersized screens cause carryover or reduced plant output. Oversized screens represent a greater capital investment and cost more per unit of production to operate. A screen using half its area to perform the required sizing still carries the oversized product its full length, incurring unnecessary operating expenses in ...

The data below were obtained on the operation of a 6mesh ...

The data below were obtained on the operation of a 6mesh (square) hammer screen at the tipple of a coal mine The screening was done to separate a very fine refuse from a fine coal stream so that it could be reprocessed. Calculate (a) the recovery and rejection of each size fraction and (b) the screen effectiveness. (10 points each) Feed to Screen, 131 tons/hr (Approximately 5% Moisture ...

(PDF) SIZE REDUCTION BY GRINDING METHODS

In the mining industry, dry grinding plants are primarily used when the downstream preparation. process requires dry material, or in order to sav e valuable water resources. Grinding is the requ ...

Bulk Density Table

H. dry 30 45 Fluorspar, fine (calcium fluoride) 80 100 Fluorspar, lumps 90 110 Flyash 30 45 Foundry sand, dry (see sand) Fuller's earth, dry, raw 30 40 Fuller's earth, oily spent 60 65 Fuller's earth, calcined 40 Galena (see lead sulfide) Ingredient Bulk Density (lb/) Loose Packed Gelatine, granulated 32 Gilsonite 37 Glass, batch 80 100

MESH and MICRON SIZES

How fine do screens get? This depends on the thickness of the wire or strand used to make the mesh. Most ISM flow control components do not contain filter screens any finer than 500 mesh. The primary reason for this is that as the mesh number rises, the space between the wires or strands becomes smaller. At some point the mesh number becomes so high that the percentage of open area is too low ...

Screen Aperture

As a rule, dry screening at less than around 5 ... The analysis procedures used for both brown and black coals are similar in that airdry coal is ground to a fine particle size (usually −212 ym) in a hammer mill then mixed and stored for later analysis. However, because of its initial high moisture content, bed moist brown coal requires longer drying than black coals. An additional ...

The World's Leading Bauxite Producing Countries

· China's bauxite reserves have decreased in size due to the increased world demand for aluminum and its byproducts. China has settled for importing bauxite from India, Australia, and Malaysia. Brazil . Number three is Brazil with 32,500 metric tons of bauxite production annually. Brazil has the world's largest alumina refinery which gets its supply from two mines in the Para state. It has a ...

Fine Powder Sizing Separating Appliions | HK ...

HK Technologies offers vibratory screeners for several types fine powder sizing and separation. (1) Classifying – separating powder solids into two or more particle size fractions. (2) DeDusting – involves separating smaller unusable particles from larger "good" particles. (3) Scalping – removing oversize particles from a product stream containing a high percentage of on size particles.

Alimunium/Bauxite Processing Flowsheet

Typical Aluminium/Bauxite Beneficiation Flow Sheet Multotec specialises in aluminium and bauxite beneficiation equipment with over 45 years of global experience and leading technology. Our team of metallurgists and engineers will partner with you to customise your equipment, helping your process run more efficiently while lowering your overall cost per ton.

Bauxite

During the Bayer's process, bauxite is fine milled. As a consequence, the red mud generated has a very fine particle size distribution. The particle size analysis of red mud was carried out using a laser particle size analyzer (MASTERSIZER S, Malvern, UK). Figure shows the particle size distribution of red mud received from ALCOA, Australia.

Screening Of Coal Fines

Derrick Corporation, Separation Technology Group, wet and dry screening, fine screening, fine sizing, vibrating screens, aggregate fines, ash recovery, ash reduction. Live Chat; Effect Of Different Screening Helix Angles On Screening . The effects of the surface charge,viscosity,relative sediment volume were studied for the collected fines,and screening performance of SWECO Vibro Energy Round ...

Everything You Ever Wanted To Know About Dry Sieve Marijuana

· Set Up the Dry Sieve Screens in the Right Order. First, set up your dry sieve screens. These screens comprise a solid frame with a fine mesh base, and they stack neatly on top of one another. Each screen has tiny holes (measured in microns) of varying diameters. The higher the micron number, the larger the hole,, a 160micron screen has larger holes than a 120micron screen. .

Understanding The Dry Granulation Process

The need for screening large amounts of fines is common to roller compaction, and the degree to which it can be managed depends on the nature of the ingredients. Any product that is removed from the rest of the batch because of particle size must be analyzed to determine what is being removed. Roller compacting the complete formula is not usually necessary. The object is to densify powders and ...

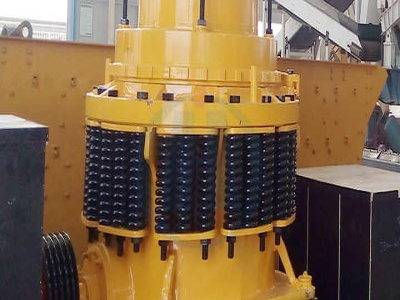

crushing and screening of bauxite

Complete set of hard rock jaw crusher, large scale cone crusher, hopper, feeder, screen and conveyors, ball mill for bauxite ... it not only undergoes mechanical process of crushing, sizing and screening, but also a certain amount of dressing, blending ... Ambica CrushtechCrushing and Screening Solutions Provider Ambica Crushtech Pvt. Ltd. is a leading manufacturer and exporter of plant and ...

A Relationship Between Screen Opening and Mesh Size for ...

h loglog plot of the relationship between screen opening and mesh size for standard sieves. solids. sieving is usually the method of choice for clas sifying granulations and coarse grades of excipients. It is used for particle size analysis and in most cases the analysis can be carried out in the dry state. When one compares mesh size to screen opening in millimeters as listed in Table 1 ...

Latest Posts

- ذروة سحق معدات مصر

- الحاجة المستخدمة سحق الحجر آلات ز

- معدات المحاجر في السعودية للمبيعات

- مصغرة مشروع مصنع الاسمنت

- كسارة فكية من الجيل الجديد

- بناء إعادة التدوير للخرسانة في سانت بريكس

- pahang خام الحديد الدولة

- صناعة تكسير الحجارة الاردن

- آلة تكسير الحجارة الكبيرة

- معمل سحق جاهز السعودية

- تاتا هيتاشي السابقين 110 سعر في مومباي كويكر

- دليل محطة التكسير المتنقلة sbm 168

- عملية مصنع الاسمنت في الهندية

- مطارق الصخر الهيدروليكية للبيع

- مورد مطحنة الكرة في الجزائر

- Skiold Type Hammer Mill

- Operations On Milling Machine

- Mill Crusher Manufacturer In New Caledonia

- Belt Conveyor Bukit Asam

- Approved Mining Permits For Industrial Sand And Gravel

- Step By Step Picture Of Te T Procedure

- Pakistan Iron Ore Mill

- Hp4 Mets Crushers

- Used Crusher Plant Price In Norway

- Hercules Crusher Cycle Price And Buying Online

- Stone Crusher Plant Detiles In Bangalore Pdf

- Stone Crushing Turnkey

- Africa Industrial Sewing Machine Dealer

- Jaw Crusher Prices Moldova

- Crusher Frame Sealing P