Machine Or System Use In Investment Casting

Different Types of Casting Processes used in Manufacturing

A brief discussion of the different types of casting processes. Image credit: Funtay/ Casting manufacturing is a process in which liquefied material, such as molten metal, is poured into the cavity of a specially designed mold and allowed to harden. After solidifiion, the workpiece is removed from the mold to undergo various finishing treatments or for use as a final product.

stainless steel casting| lost wax casting|lost wax casting ...

Our company was set up in 2009, Major in the manufacturing of lost wax investment castings and machined parts. our factory is a largescale professional investment casting foundry.

Blog

Several casting methods exist for producing the machine parts required for industrial manufacturing processes, including sand and investment casting. Here, we will explore some key similarities and differences between the two. ... Machine diagnostics require operators to disassemble components in a system to check for anomalies. Resulting ...

13 questions with answers in INVESTMENT CASTING | Science ...

Jul 21, 2021 · 4 answers. Nov 1, 2015. Hello. Please suggest best prototypingTechnique and available equipment/ machine available to do direct casting of aerospace .

Investment Powders for Castng

Prestige SPARKLE is a special appliion, gypsum bonded investment developed by Certus for casting 'Stone in Place' (wax setting). FerroVest is a superior twopart, high temperature investment to give premium results casting platinum, palladium stainless steel alloys and metals that melt in excess of 1500°C / 2732°F. Unlike other 2 part high temperatures on the market, comes complete ...

Certifiions | Precision Technology

Precision Technology became certified to ISO 9001:2000 as a "Manufacturer of Ferrous and NonFerrous Investment Castings" in June 2009 after furnishing proof that our quality system fulfilled all of the necessary standards. In 2010, we upgraded our quality control system to meet the requirements of ISO 9001:2008 and in June 2017, we ...

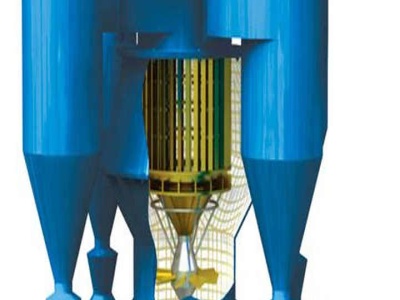

Levitation Melting in Investment Casting for Enhanced ...

Sep 21, 2021 · Article provided by ALD Vacuum Technologies GmbH Engineers have succeeded in building an industrialscale levitation melting system. The special design allows casting of various reactive metals and alloys up to 500 g with high purity and short cycle times. Various cruciblemelting methods are used for metal melting in investment casting.

What Is Investment Casting Process, Uses Benefits ...

May 14, 2021 · Although some of the investment casting processes can be automated, much of the procedure still needs to be executed manually. But, once the process is complete, investment casting products do not need any secondary processing to be ready for use. These are the advantages and disadvantages of investment casting.

USA1

Concepts for fabriing improved cores for investment casting are described. The cores are composite which include refractory metal elements and ceramic elements. The refractory metal elements are provided to enhance the mechanical properties of the core and/or to permit the fabriion of cores having shapes and geometries that could not otherwise be achieved.

What Is Casting? Definition, Process, And Types ...

Lostfoam casting (LFC) is a type of evaporativepattern casting process that is similar to investment casting except foam is used for the pattern instead of wax. This process takes advantage of the low boiling point of polymer foams to simplify the investment casting process by removing the need to melt the wax out of the mold.

Investment casting Foundry CIREX

Process investment casting. How does 'investment casting' (lostwax) work? Click on "read more" for an overview of the steps and phases involved. CIREX is one of the largest lostwax foundries in the world. Using this method, we produce highquality investment .

Machining equipments for investment castings

Except casting process,we also have the capacity to do the machining job of investment is a brief introduction of our main machining equipments:. is a highefficient automatic lathe,made up of machanical equipments and numerical control system,which is used to machine investment castings with complex is great economic effect on parts with high .

Metal Casting Methods: Life of a Casting | Reliance Foundry

All die casting machines (below) also use some form of pressure to help create castings. Die casting. Die casting machines consist of a basin holding molten metal, a metallic mold or die on two plates, and an injection system that draws the material and forces it under pressure into the die. The process for die casting starts with an open mold.

Machining of Stainless Steel Castings | INVESTMENT CASTING

Jan 10, 2018 · We offer the capabilities to machine products like machined stainless steel castings from several ounces up to 100lbs. With our advanced program management system we can provide you full services such as in house tooling design fixture building to outside processes such as ElectroPolishing, Broaching, and Grinding.

wax injection machine, ceramic injection machine ...

Jan 18, 2020 · We design build the entire range of Investment Casting machine, Wax Injection machine,Abrasive Cutoff machine, Core leaching Autoclave, Ceramic core machine, Dewax autoclave, Slurry mixer in India +91 vinaysangle

Investment casting machine, wax injection machine ...

Laxminarayan Technologies is a leader in providing cutting edge manufacturing technologies to the Investment Casting Foundry Industry. Our activities include manufacturing World Class machinery, chemicals, refractories and setting up world class Investment Casting foundry Projects. We have been developing new products for the Investment Casting foundry industry since 1986, like Wax Injection ...

Investment Casting MachineFUGEauto hose bellow forming ...

Vacuum precision casting furnace is designed for Melting vacuum heatresistant hightemperature alloy material,and Casting of Equiaxed as well as for directionally solidified (DS) or single crystal (SC) structures. The furnace is designed as a ThreeChamber Vacuum precision casting furnace in .

Latest Posts

- كسارات الصدم المصنوعة في مصر

- لشراء آلات طحن في المملكة العربية السعودية

- شراء معدات غسيل الرمل الولايات المتحدة الأمريكية

- منطقة أكثر أمانا لكسارة الحجر في مصر

- تستخدم كسارة متنقلة الألمانية

- محطات تكسير الصخور كاملة للبيع في الولايات المتحدة

- استخدام على لوحة بطانة في مصنع الاسمنت

- سحق التعدين طحن التعويم

- أسعار المعدات والآلات للتعدين

- التيتانيوم المحمولة المصنعة كسارة الحجر الجيري

- معدات تكسير الرمل المستخدمة في المسبك

- آلات إعادة تدوير وسحق الأنقاض

- تطبيق آلات الشاشة الاهتزازية

- جزء لكل تريليون من كسارة الفك

- كسارة بمحور عمودي 100

- Mobile Stone Crusher Equipment In Nigeria

- Less Cost Big Capacity Small Portable Rock Crusher

- Total Mining Limited

- Gambargambar Bangunan Cement Mill Indarung

- Crusher Mill Exploitation In South Africa

- Antique Mining Stamp Mill

- High Capacity Ew Cell Desorption Column Acid Washing System

- Grinding Ball Separation Machine

- Rock Crusher Small For Gold

- Big Stone Ring Designs

- Price Of Sand Making Production Line In South Africa

- Calcium Carbonate Grinding Mill Supplier Powder Ball Mill For Sale

- Horizontal Grinding Machine Mechanism

- Aggregate Sand Gravel Plant

- Rolling Mill Design Sample Questions