Crushing And Pre Homogenizing Of Clinker

(PDF) A review on kiln system modeling

Grinding of clinker consumes power in the range of kWh/ton of clinker produced. These and other pyroprocessing parameters make cement production costly. The pyroprocessing process in kilns and ...

Crushing And Pre Homogenizing Of Clinker

Crushing Unit In A Clinker Cooler. Technological Features Crushing raw materials pre homogenizing materials arranging ingredients efficient grinding homogenizing materials suspending pre heater and decomposing furnace new type cooler cement dosing and grinding Details Lime Kiln Production Capacity by crushing and pre homogenization preparation of raw meal homogenization preheating ...

BASIC CEMENT PLANT LAYOUT – Process Cement Forum – The ...

· Cement production line includes crushing and prehomogenization, raw material preparation homogenization, preheating decomposition, cement clinker sintering, cement grinding and packaging etc. CHAENG have the ability to built 300t / d ~ 3000 t /d cement production line independently, And has extensive experience in the design and construction, built many large cement .

Blending Silos In Cement Plant

Gravitytype homogenizing silos or continuous blending and storage silos that are used in modern plants reduce power consumption. In these silos, material funnels down one of many discharge points, where it is mixed with the help of an inverted cone. Although gravitytype silos may not give the same blending efficiency as airfluidized systems, more and more new plants prefer gravitytype ...

GrafGalenStraße 17 industry

of cement and clinker – ranging from individual machines and automation systems through operations maintenance support ... cess, including the crushing, blending, storage, homogenizing, efficient grinding systems for raw and solid fuels – the quadropol ® vertical roller mill or the polycom high pressure grinding roll – and analysis technology. For this purpose, we use the ...

crushing and pre homogenizing of clinker

crushing and pre homogenizing of clinker crushing and pre homogenizing of clinker Milling is also known as grinding it is a material more refining process Contact Now Pre list of big construction companies in south africa Next quarry man concrete crusher hire Jaw get price. Cement Plant Clinker Grinding Station In Egypt Buy . 1. Crushing and Prehomogenizing: Most of the raw ...

What processes do special refractory raw materials need to ...

· (2) Clinker crushing processing During the processing of special refractory products, the clinker should be processed into various particle sizes as required, such as coarse particles: 5~3mm, 3~1mm, 1~; fine particles: less than or less .

Stressed, brittle, and reactive—Crushing clinker at its ...

· The work, led by ACerS member and assistant professor Rouzbeh Shahsavari and former graduate student Lu Chen, began with examining clinker as it cooled postkiln. By looking at the crystal and atomic structures during the five phases of cooling, they were able to hone in on the stresses and defects that make some clinker more brittle than others, and thus, easier to grind.

Preparation Of Cement Raw Material | Cement Mill, Cement ...

The raw material production of cement plant can be classified into four steps: crushing, grinding, mixing and homogenizing. Crushing: the limestone and other materials are crushed into small pieces by cement crusher, such as hammer crusher, cone crusher, jaw crusher, impact crusher, etc. Mixing: according to the requirement of clinker, compound ...

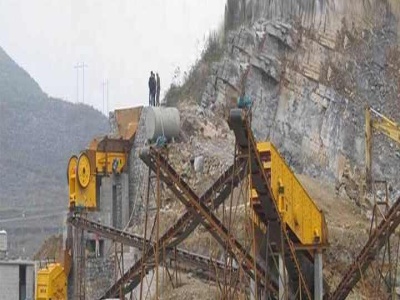

Raw Material Crushing and Prehomogenization_Dry Process ...

During cement manufacturing process, the majority of raw materials, including limestone, clay, iron ore, coal, etc. will be crushed. Specifically, due to larger granularity and higher hardness, the crushing of limestone that is maximally consumed in cement process plays critical role in the raw material crushing.

What are Features and Advantages of Cement Production Line?

In the cement production line, we need not only the crushing machinery, but also the grinding machine. The whole production process of cement is generally as follows: homogenizing preparation of raw material raw material homogenization preheat decomposition the burning of cement clinker cement grinding mill cement the process flow, different cement making machines ...

A review of the effectiveness of Life Cycle Assessment for ...

Homogenizing and grinding procedures of cement production are completed in the raw milling process. Raw meal preparation is for pyroprocessing, where all raw materials such as limestone, shale, iron ore, and clay are mixed. Both chemical composition and variations in the raw material composition have negative impacts on clinker quality. Therefore, it is crucial to reduce the variations in ...

clinker grinding unit, clinker grinding machine, clinker ...

Clinker is a necessary step in the cement production process. The production process is also very complied. It is roughly divided into five steps: crushing and prehomogenization, raw material preparation, raw material homogenization, preheating decomposition and clinker burning. to make. Among them, the crushing and prehomogenization include: crushing and prehomogenization of .

Automation and Control in Cement Industries

the prehomogenizing possibility is much more important, if appropriate vertical or horizontal layering and perpendicular random or controlled extraction is applied. Figure 2. Typical blending systems The prepared raw materials are stored in silos for the next technological step, which is the raw material grinding and blending system. Raw Material Blending At the next technological unit ...

crushing and pre homogenizing of clinker

Crushing And Pre Homogenizing Of Clinker. 8. Clinker Storage A clinker storage silo with capacity of 15000tons and an open yard with capacity of 20000tons are built up in the plant. Under the clinker silo, the rod gate and the motorized discharging gate are installed. The clinker discharged by these equipment is fed to different belt conveyors . Energy Saving Cement Manufacturing Equipment ...

PYROFLOOR²

Since the commissioning of the first KHD clinker cooler in 1936, ... completely preprogrammed and tested, stateoftheart Programmable Logic Controller (PLC) with multifunction display panel. Optionally, an advanced expert system called 2® PYROFLOOR Cooler Controller (PFCC) can be integrated with the hydraulic PLC. The PFCC is preprogrammed with advanced algorithms that .

Process Of Prehomogenation In Cement Industries | Crusher ...

raw meal homogenizing silo cement industry. This page is provide professional raw meal homogenizing silo cement industry . PreHomogenization Raw . new dry cement production process is the most . All About Cement | Cement Technology | Cement Factory . » Process of cement production line | Home; About Us; . metallurgy industry and etc. Throught technical renovations, . Crushing .

Cement Plant Conveyor Belt

· After the primary crushing, the limestone is crushed for a second time to make the size less than 6 inches (150 mm) until it is crushed to less than 1 inch (25 mm) for storage and proportioning. Storing and homogenizing. Crushed limestone and other raw materials (such as sand, clay, fly ash and shale) are transported to the raw material storage area and then mixed in the required ratio. Raw ...

What is Clinker Block?Composition, Use, Properties Advantages

Compressive strength of clinker bricks is 250 to 350 kg sq cm. (what is clinker block) Clinker blocks is used following purpose – As a safety barrier. For fixing windows and doors. To decorate the walls. To differentiate the appearance of the structure. Advantages of Clinker block. Ash is used as an aggregate in the cinder block.

Process Of Prehomogenation In Cement Industries | Crusher ...

raw meal homogenizing silo cement industry. This page is provide professional raw meal homogenizing silo cement industry . PreHomogenization Raw . new dry cement production process is the most . All About Cement | Cement Technology | Cement Factory . » Process of cement production line | Home; About Us; . metallurgy industry and etc. Throught technical renovations, .

Portland Cement Manufacturing – Ordinary Portland Cement ...

Portland cement manufacturing process can be divided into 6 steps: raw material crushing, prehomogenization, fine grinding, clinker production, cement grinding, cement packing, etc. In these processes, we need the assistance of different kinds of cement equipment, such as cement kilns, cement mills, and cement crushers.

Cement Crushing Plant | Clinker Production Line | SINOMALY

Cement Crushing and Grinding Plant. Introduction to Cement Crushing and Grinding Plant . We offer a series of equipment to form an automated production line for cement plants, as well as offer a series of project services, including process design, civil construction, complete sets of equipment, installation and commissioning, and technical assistance. Using the clinker production line ...

cement manufacturing

Prehomogenizing is necessary if the limestone shows large fluctuations in chemical composition and when handling large quantities of raw material. Prehomogenizing is used primarily for the main components in cement production viz. Limestone and clay/silcastone, and other components of raw materials such as sand and ironore are nearly always homogeneous and therefore need not be blended

No more blockages. It's the clinker crusher your process ...

Crushing it, 24/7 with the Heavyduty Roll Breaker . Every cooler will experience clinker boulders from kiln – it's how you deal with them that counts. The Heavyduty Roll Breaker can crush boulders up to m with ease. No blockages. No downtime. Just high productivity, low maintenance clinker crushing.

crushing and pre homogenizing of clinker

Crushing and pre homogenizing of clinker crushing and pre homogenizing of clinker Milling is also known as grinding it is a material more refining process Contact Now Pre list of big construction companies in south africa Next quarry man concrete crusher hire Jaw Crusher Efficient jaw crusher Online chat Product Category More.

Latest Posts

- مصنع كسارة السويد

- كسارات الحجر مصنعي

- معدات تكسير قصب السكر بنين

- كسارة متنقلة شمال العراق

- وحدة تغذية بالاهتزاز للبيع

- حالة تعدين الحجر الجيري في الجزائر

- آلة صنع مسحوق أكسيد الحديد

- ورقة تدفق عملية إنتاج الذهب

- VSI كسارة مبادئ التشغيل

- المعدات الكهربائية المستخدمة لغسل التعدين

- كسارة الفك الديزل للبيع في اليمن

- pyd pyz كسارة مخروطية سلسلة

- يستخدم لمسحوق الحجر الجيري في الجزائر

- الكابلات الكهربائية مصنع لتجهيز

- Excavator Mounted Stone Crushing Bucket

- Costos Del Mineral Dolomita

- Vibrating Screen Price List

- Diagramas De Maquinas Trituradoras De Plastico

- Small Gold Mining Machinessmall Gold Mining Mills

- Iron Sand Processing Plant Detail Design

- Granite Grinding Tools In Mesa

- Komastu Komastu Mobile Stone Crusher In Côte D Ivoire

- Stone Vibration Feeder

- Latest Mill Board Machinery

- Ball Mill Specifiion Ball Mill Machine Manufacturer

- Crusher Control System Principles

- Hold Back Arrangement In Gearbo May

- Cara Menghitung Kapasitas Produksi Dari Sebuah Crusher

- Used Portable Crushing Plants Price

- Quarry Profile Pdf