Separation Of Ore And Gangue

Notes OCCURRENCE AND EXTRACTION OF METALS

For example, the tin ore, tin stone SnO 2 itself is nonmagnetic but contains magnetic impurities such as iron tungstate FeWO 4 and manganese tungstate MnWO 4. Ore Nonmagetic wheel Magnetic wheel Nonmagnetic gangue Magnetic ore Fig. : Magnetic Separation The finely powdered ore is passed over a conveyer belt moving over two

Explain the 3 separation techniques for remving the gangue ...

· 1) hydraulic washingThe ore particles are poured over a hydraulic classifier which is a vibrating sloped table with grooves and a jet of water is allowed to flow over denser ore settle in the grooves while the lighter gangue particles are washed away. This method is used for concentration of heavy oxide ores of lead, tin, iron etc.

Iron ore mining and dressing

· Ore processing (or ore dressing) is the separation of iron ore from gangue in order to optimize the blast furnace process! In principle, the undesirable gangue can never be completely separated from the iron ores during ore dressing. This means that a certain amount of unwanted elements always enters the blast furnace process. Slagforming aggregates (and other special .

「magnetic separation gangue」

Magnetic separation is used to separate magnetic gangue from the desired ore, or conversely to remove a magnetic target ore from nonmagnetic gangue. DMS is also considered a physical separation. Chemical separation. Some ore physical properties can not be relied on for separation, therefore chemical processes are used to separate the ores from . Inquire Now; Kaolin Purifiion,Gravity ...

Chrome Ore Beneficiation Process | Chromite Processing ...

· The density of chromite ore is slightly higher than that of its other magnetic gangue ore. Therefore, the separation of ferrochromium from other minerals can be realized by gravity separation. Use spiral chute to separate the concentrate process tailings and the scavenging process concentrate respectively. As shown in the gravity beneficiation process result, both of the grade of concentrate ...

Process for separating sulfur from ore

A process for separating sulfur from particles of sulfur ore containing elemental sulfur and gangue wherein said particles are not substantially larger than 30 Standard mesh, said process comprising the steps of. (1) mixing said particles with a dilute aqueous solution having a density and containing water and an agent capable of combining ...

Name Of Gangue Mineral In Iron Ore

Gangue Wikipedia . the separation of mineral from gangue is known as mineral processing, mineral dressing, or ore is a necessary, and often significant, aspect of can be a complied process, depending on the nature of the minerals involved. for example, galena, an ore of lead, is usually found in large pieces within its gangue, so it does not normally need extensive ...

Sorting Mineral Ore And Gangue Ore

Mineral sorting systems allow major mining companies to reduce minerals dilution and optimize process flows by separating ore from gangue on a rock by rock basis. Read more. sorting mineral ore and gangue ore | Clinker Grinding Mill. sorting mineral ore and gangue ore. We supply professional ore mineral processing equipments including ore mineral crushing plants, grinding equipments, screening ...

how to separate copper and gangue

Gravity Separation is used to separate mineral and gangue with a large difference in their Specific Gravities. Chromite, tin, tantalite and various heavy metals are amenable to this principle. Some gold ores contain Free Gold which can be recovered by gravity separation and this is the traditional method used in artisanal gold mining. Learn More. How Copper is Mined and Refined: "A Story Of ...

mineral processing | metallurgy | Britannica

A successful separation of a valuable mineral from its ore can be determined by heavyliquid testing, in which a singlesized fraction of a ground ore is suspended in a liquid of high specific gravity. Particles of less density than the liquid remain afloat, while denser particles sink. Several different fractions of particles with the same density (and, hence, similar composition) can be ...

Environmental impact of gangue minerals in mine tailings

In mining, gangue (/ ɡ æ ŋ /) is the commercially worthless material that surrounds, or is closely mixed with, a wanted mineral in an ore is thus distinct from overburden, which is the waste rock or materials overlying an ore or mineral body that are displaced during mining without being processed, and from tailings, which is rock already stripped of valuable minerals.

OVERVIEW OF MINERAL PROCESSING METHODS

Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals. It is done in order to produce a concentrate containing most of the ore minerals and a ...

Chapter 2: An introduction to mining

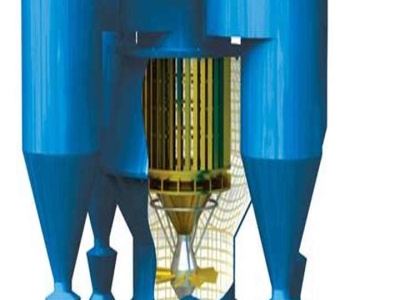

There are four important methods to separate ore and gangue minerals and to concentrate ore minerals: ... Magnetic separation can remove magnetic gangue minerals or in the case of iron ore mining to separate the magnetic ore mineral into a concentrate of magnetite (Fe 3 O 4) Gravity separation uses density differences to separate heavier minerals from lighter. Gold panning is a method of ...

Liberation Size and Beneficiation of Enyigba Lead Ore ...

gangue with minimum metal loss in tailings, the need to develop and employ a sustainable, effective and relatively economical method of separation is imperative. The concentration of the valuable minerals from the ga ngue involves exploitation of the differences in the mineral properties of the ore after effective comminution [2].

Gravity Separation or Lavigation │Chemistry Desk

· Gravity Separation or Lavigation. This method of concentration of ore is based on the difference in densities of the metallic ore and gangue particles powdered ore is treated with a stream of running water when the lighter gangue particles are washed .

Gravity separation method is based upon : (A) Preferential ...

Gravity separation method is based upon : (A) Preferential washing of ores and gangue particles (B) Difference in densities of ore particles and impurities (C) Difference in chemical property of ore particles and impurities (D) none of these

Comprehensive Analysis of Mineral Processing Methods and ...

· Gravity separation is the main mineral processing method for the separation of wolframite, cassiterite, placer, coal, and manganese ore, and is also widely used in the separation of a rare metal sand mine. The gravity separation is suitable for a wide range of particle size, from hundreds of millimeters to less than one millimeter, and the cost of mineral processing is low, the pollution to ...

Latest Posts

- تستخدم مطحنة الكرة لالكلنكر طحن 130tph

- خط إنتاج كسارة حصاة

- مطحنة للخضروات الجافة

- كسارة الحجر 200 طن دا ذ للبيع

- جوز الهند المطرقة مطحنة آلة

- تستخدم الدولوميت مخروط محطم للبيع أنغولا

- مصنعي كسارة الرطب

- مصنع الذهب محمول ل بيع مصر

- ريمون مصانع صغيرة مطحنة الفحم

- مطحنة رماد الكالسيوم متناهية الصغر

- مطحنة الكرة لسحق الرواسب

- السحق الكرة مطحنة الفحم

- المورد آلة كسارة الرمل

- أنواع خوذات السلامة التي تستخدم في الكسارات

- كسارات حجرية في السودان

- Cost Portable Rock Crushers

- Cone Crusher For Sale In Philipines

- Ball Mills Especiallyball Mills Es Lished

- Top Stone Crusher Company In Chennai

- Limestone Powder Conveyor Manufacturers Antigua And Barbuda

- Workshop Manual For Xr S Crusher

- New Version For Sand Stone Quarry

- Crusher Produsen Mesin Uruguay

- Slate Pencil Manufacturing Machines

- Plastic Granulator Pulverizer

- How Much Kg Of Balls Can Be Used For 20 Kg Ore In Ball Mill

- Hammer Crusher Israel For Sale

- Sme Mining Engineering Handbook Torrent

- Mill Janher Jhc 24s

- Pabrik Penghancur Tetap Bekas Di Scandnavia