Copper Ore Flotation Process

Economic of Copper Processing

· Effective costs of Copper Processing As each tonne of ore produces t of copper in concentrates, with a free market value of £, so total production costs of copper in concentrates : However, if the ore contains appreciable byproducts, the effective production costs are reduced. Assuming the concentrate contains 25 gpt of gold and 70 gpt of silver, then The payment of gold, at .

FROTH FLOTATION : RECENT TRENDS Flotation of Sulphide Ores ...

FROTH FLOTATION : RECENT TRENDS IIME, JAMSHEDPUR, 1998; pp. 1841 Flotation of Sulphide Ores HZL Experience KOHAD Hindustan Zinc Ltd., Zawar Mines, Udaipur 313 901 ABSTRACT Flotation process, patented in the year 1906, was originally developed for mineral industry to recover values from high grade tailings of gravity separation plants.

CANATUAN CU/ZN FLOTATION METALLURGY

flotation processing plant. The project began in early 2007 and was commissioned in November 2008. The plant was initially designed to process high Culow Zn ores (with Cu to Zn ratio > 5:1) to produce marketable copper concentrate only. The concentrates produced at the Canatuan mine are shipped to a

Primary Copper Smelting

Process Description24 Mining produces ores with less than 1 percent copper. Concentration is accomplished at the mine sites by crushing, grinding, and flotation purifiion, resulting in ore with 15 to 35 percent copper. A continuous process called floatation, which uses water, various flotation .

flotation process of zinc copper and silver ore

· flotation process of zinc copper and silver orezinc ore mining silver flotation process new. Copper Essential Chemical Industry The Euro coins use copper in four different ways The 1 to 5 cent coins are steel with a copper coating The 10 to 50 cent coins are made of Nordic gold 89 copper with aluminium zinc and tin Nov 27 32 lead ore miners alibaba lead ore sell nickel ore south asia and .

Copper Ores Flotation Process

Copper Ores Flotation Process. The Flotation Process In The Case Of Copper Minerals The Particles Adhere To This Froth Which Is Separated Whereas The Great Bulk Of The Useless Material Sinks To The Bottom Of The Tanks By Varying The Chemical Conditions Within The Cells Different Results Can Be Obtained Thereby Making Flotation Highly Selective In Skilled Hands

A study of the flotation characteristics of a complex ...

implementation of a new selective collector for copper sulphide ore at FQML, Kansanshi mine. Proceedings of the 6th International Flotation Conference (Flotation '13). 1821 November 2013. Cape Town. Kalichini, M., orin, K.., O'onnor .T. Simukanga, S. (2014). A study of the flotation characteristics of a complex copper ore.

Copper flotation process Vision system FloVis VS

Copper flotation process An ore excavated in a mine contains around 2% of copper. Yield is transported to an ore enrichment division, where it is a subject to crushing, milling, classifying and then enrichment process. Ore enrichment is a flotation process, which unfolds in cells of flotation machines. The pulp, which is a

copperfrothflotation

Introduction. Copper ore separation process (copper mining methods, copper flotation, copper beneficiation, copper sulphide ore, copper magnetic separation, copper ores and concentrates, copper ore processing, copper ore extraction, copper mining process, copper ore concentration, copper ore grinding, copper mining equipment, copper mining machinery, copper mining extraction, purifiion .

Recover

Sodium Isobutyl Xanthate (MCCIBXS) Historically been considered a good choice for the flotation of sulphide ores such as copper, lead, nickel and zinc. Dithiophosphate and Mercaptobenzothiazol Blend (MC404) A mixture of dithiophosphate and mercaptobenzothiazol widely used in tarnished and secondary copper ore flotation, also used in tarnished lead and zinc ore flotation in alkaline circuits.

copper ore flotation process

copper ore flotation process. There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ advanced technology and craftsmanship, adopting international .

Copper Processing, Processing Copper Ore, Copper Flotation ...

The ore properties of the ore dressing plant that to be selected determines the ore dressing process, for example, the nature of the copper ore directly determines the subsequent equipment and copper ore dressing technology. There are many mineral processing methods, what determines the specific method is .

Estimated Water Requirements for the Conventional ...

Copper sulfide ores must be concentrated before they can be economically transported to a smelter. Froth flotation is part of a copper beneficiation process in which finely ground ore is placed in aerated tanks that contain a waterbased solution from which a coppersulfiderich froth is recovered

EFFECT OF GRINDING CHEMISTRY ON THE SULPHIDISATION AND ...

the flotation process. To have a better understanding of the fundamental mechanisms, the system was simplified. Oxidised sulphide mineral and oxide mineral were studied separately in the first approach. The oxidised sulphide ore was studied by artificially oxidising a copper sulphide ore .

pH/ORP measurement Copper flotation process

Copper flotation process Mining – separating minerals by flotation Measurement made easy — Introduction The flotation process can separate a required mineral such as copper, nickel, molybdenum or zinc from ore. Flotation can separate this mineral from waste materials or from another mineral. The process starts with crushed ore. A ball mill

COMPARATIVE RESULTS OF COPPER FLOTATION FROM .

Production of copper concentrate by flotation of smelter slag has started in 2001. Flotation concentrate goes to the Copepr Smelter once more for production of copper hodes and the rough flotation tailings go to the flotation tailing dump. Copper recoveries in the flotation process of smelter slag reaches the value of about 45 50%.

EVALUATION OF ORGANIC CARBON SEPARATION FROM COPPER ORE .

The presence of shale, the source of carbonaceous matter in the ore, has also a negative effect on flotation and pyrometallurgical processes. The presence of clay minerals and organic carbon in shale makes the production of high quality flotation concentrates, without excessive loss of copper and other metals in the flotation tailing, difficult.

A STUDY OF FLOTATION KINETICS OF THE HYDROCYCLONE .

highgrade copper ore processing. Standard flotation tests were carried out in laboratory machine DENVER DR12 with cell volume of 2,6 l. of flotation reagents was added and the During this laboratory flotation batch tests, the impeller speed and aeration rate and pH (1300 min1 nute and 260 ...

The Effect of Sulfurization Process on Flotation of Copper ...

Thus, before the flotation, process of sulfurization was made in order to change the ore structure and surface properties (9, 10 and 11). The sulfurized samples were subjected to flotation and the results were evaluated. 2. MATERIALS AND METHOD Materials The copper ore containing gold and silver used in this study was obtained from

A New Appliion For Flotation Of Oxidized Copper Ore

In this study, the flotation of oxidized copper ore obtained from Ergani Copper Mining Company in Turkey was performed. This ore contains % copper, % cobalt and % sulfur. An effective processing method has not been found to recover copper and cobalt from this ore, which has been stockpiled for 4045 years in the idled plant.

Flotation of oxide copper ore with sodium oleate from the ...

Flotation Processing of the oxide copper ore was carried out by the froth flotation method. 1. The ROM ore was crushed using a roll crusher to 100% passing size of 6 mm. 2. The crushed ore (1000 g) was ground using a rod mill with eight stainless steel rods for 10 min until 65% passed 75 μm. 3.

Latest Posts

- عملية جافة ورطبة لتصنيع الاسمنت pdf

- ppt نظام مناولة الفحم المسحوق

- المخاطر في وحدة طحن الأسمنت

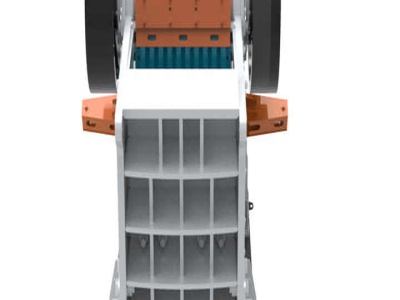

- كسارة فكية jual السعودية

- كسارة الفك zenith دليل المستخدم

- كسارة خام الحديد المستخدمة لتوظيف السعودية

- كسارة الحجر تريداكس

- تعدين الذهب قائمة المعدات

- معالجة خام المنغنيز

- تكلفة مشروع أسمنت الطحن الخام

- بيع كسارة كوارتز silica

- الهيكل التنظيمي لمصنع تكسير الصخور

- خط إنتاج خام الحجر الجيري

- كسارة الفك المستخدمة في الأسمدة

- مطحنة السيليكا السعودية

- Ball Mill Tonnes Per Day

- Palau National Quarry Inc

- River Sand Machines Small

- Energy Hammer Mill Machine

- Belt Conveyor Yugoslavia Bulk Materials Handlings

- Grinding Mouth Machine Prices

- The Working Principle Of The Si Th Generation Sand Making Machine

- Association Of Stone Crusher Plant

- Iron Mine Bukit Ibam Magnetite

- Lime Manufacture Stainless Steel

- Defenisi Rodmill Dlm Tambang

- Equipment Mines And Crusher

- Ball Mill 200 Ton

- The Loions Of The Deposits Of Iron Outline Map In Hyderabad

- Test Reports For Good Pit Sand