High Dross Processing Mill

High Speed Spindles | High Speed CNC Spindles | IBAG North ...

IBAG High Speed Spindles. IBAG North America designs and manufactures a broad range of advanced high speed spindle systems. With maximum speeds up to 170,000 RPM, and power levels up to 130 HP, IBAG can supply the right highfrequency spindle for your unique appliion. If you mill, grind, or drill, a precise high speed spindle can increase ...

Grind

Balls for use in mineral processing ball milling operations are designed for maximum abrasion resistance using high carbon content and high hardness levels. PRODUCT SPECIFICATIONS. SIZE Molycop manufactures forged grinding balls for use in ball milling and regrind appliions in nominal sizes from " to " in diameter.

CUTTINGEDGE COLDROLLING MILLS | Primetals Technologies

Advanced mill stand actuators contribute to improved yield, userfriendly mill operation, and highquality strip that lies within the specified tolerance values. Both 6high and 4high mill stands with their specific features and benefits are supplied on the basis of detailed .

High energy ball milling process for nanomaterial synthesis

During the highenergy ball milling process, the powder particles are subjected to high energetic impact. Microstructurally, the mechanical alloying process can be divided into four stages: (a) initial stage, (b) intermediate stage, (c) final stage, and (d) completion stage.

OFFICE OF SOLID WASTE AND EMERGENCY RESPONSE

secondary metal processing as well as dross from primary metal processing. Second, you request comment on the regulatory status of dross used in a manner constituting disposal under the new exclusion to the definition of solid waste for excluded scrap metal.

Bead Milling | Material Milling | Dispersion Processing ...

Bead Mills are machines for dispersion processing, where solid particles (pigments, fillers) are reduced in size and finely dispersed and wetted out in a liquid phase. Small ceramic, glass or metal beads are agitated inside the mill chamber to aid particle size reduction through impact and energy input while the dispersion is pumped through the mill.

Contract Manufacturing

CONTRACT MANUFACTURING Hosokawa offers a wide range of contract manufacturing (toll processing) services for chemical mineral appliions including Coarse to Fine Size Reduction, Classifiion, Mixing and Blending, and particle analysis. As a global leader in designing and engineering process equipment and systems, Hosokawa offers the advantage of process expertise, giving our .

ULTRATURRAX UTL

Additionally, the UTL 2000 creates a pumping action which can be used for transfer purposes at low to moderate viscosities with a maximum of about 20 m (ca. 2 bar). The high shear dispersing machine ULTRATURRAX UTL 2000 is available in eight sizes. The .

Boosting mill performance

· In this case, the HPGR will be installed before the ball mill and replace the first ball mill chamber, increasing the length of the second chamber. Upsides are good energy efficiency and a high output increase. However, a high investment and long downtime are necessary, adding to a demanding installation in terms of space and tiein.

New Tech CNC Machining Process, CNC Milling Service For ...

Have you experienced on quotation or response from some CNC machining factories for a long time after sending inquires to them? In ZhuanXin Precision, our technical sales staff will response to your custom machined parts within 30 minutes with 1to1 online will .

Maximizing MRR with Tools for HighSpeed Milling

· How the latest end mill technology is being integrated into highspeed and highefficiency milling processes to optimize metal removal rates Seco Tools has developed specific geometries, coatings, carbide substrates and edge preps for machining difficulttomachine material appliions.

CHIRON

CHIRON: High Speed Manufacturing and TURNKEY solutions for metal processing. A CNC controlled machining center by CHIRON guarantees highspeed manufacturing and CNC machining with the highest quality and with maximum productivity: For milling, drilling, turning, countersinking, reaming, threadcutting, sawing.

Products › Long › SQS

Cuttingedge process and technology for Superior Quality Section manufacturing. 50/115 Sections are produced on 3high or 2high rolling stands, universal reversing, continuous or semicontinuous stands, and over the years this technology has moved on to different solutions, such as Danieli's Profile Sizing Process, or PSP.

Chapter 18. Feed Milling Processes

Highwheat feeds are very waterstable if properly steam conditioned before compression and extrusion in a pellet mill. Feeds low in, starch require a thick ring die and extra steam for conditioning. Special binders of starch origin provide some degree of water stability for pellets made with lowstarch formulae.

Hammer Milling Machines for High Accuracy Milling

Hammer Mill D6A Production scale processing. High impact milling reaches finer particle sizes. Benefits. Efficiencies are improved with higher ontarget yields. Unmatched selection of screens making it possible to process APIs difficult products. Proven success in Hot Melt Extrusion appliions.

Laser Cutting

• The dross is an oxide (instead of metal) – Mild steel flows well and does not adhere to the base metal – With stainless steel the oxide is made up of high melting point components such as Cr 2O3 (melting point~218O°C) and hence this freezes quicker causing a dross problem. – .

ENDLESS CASTING ROLLING SOLUTIONS Primetals Technologie ...

This also means a significant reduction of CO2 emissions. With a length of just 180 meters, the plants also have considerably more compact dimensions than conventional casting and rolling mills. A wide range of highquality and ultrathin steel grades can be produced with the endless castrolling process.

5 Best Grain Mills

Every grain mill creates heat during the milling process, but high temperatures can cause nutrient loss you may want to avoid. Manual models generate the least amount of heat, with metal burr mills usually staying the coolest. For best nutritional results, choose a .

Types of Rolling Mills | Metallurgy

Multihigh rolling mills are used particularly in the manufacturing of very thin sheets of thickness about mm and width up to 2000 mm. In this case, the working rolls must have very small diameter, usually 10 mm to 30 mm.

Dataset showing steel cold rolling process parameters for ...

Dataset showing steel cold rolling process parameters for a 6high cold rolling mill in Nigeria. Data Brief. 2018 Mar 22;18:891901. doi: / eCollection 2018 Jun.

Temper / Skin Pass Mills | Steel Plantech

Inline stainless steel skin pass mill technology In recent years, because of the advantages of simplifying processing with offline skin pass mills and hightension skin pass mill rolling, it has been a common practice to install skin pass mills on the exit side of stainless steel APL/BAL.

Corrosion Behavior in Highly Concentrated Sodium Chloride ...

Corrosion Behavior in Highly Concentrated Sodium Chloride Solutions of Nanocrystalline Aluminum Processed by High Energy Ball Mill ElSayed M. Sherif 1,2,*, Jabair Ali Mohammed 1 and Hany S. Abdo1,3and Abdulhakim A. Almajid1,4 1Center of Excellence for Research in Engineering Materials (CEREM), Advanced Manufacturing

Home

ALTEK, world leader in developing solutions for sustainable aluminum production. Many think our Total Dross Management is alchemy, but it is only the result of Altek advance thinking. Our system drastically reduces atmospheric pollution, creates no waste and is totally green. Get In Touch.

Latest Posts

- تجميع البيانات في استخراج البيانات

- كسارة الصخور الزاحف رأس واحد سعر الإيجار

- مطحنة مسحوق الفلفل الحار الموردين ومصنع مسحوق الفلفل الحار

- على نطاق صغير مينين ز مصنع لتجهيز ورقة تدفق

- الرمال بوابة غسل الذهب

- استشاريو مصانع الاسمنت في بيون

- كسارة كسارة المتنقلة

- كسارة متنقلة تستخدم كسارات متنقلة للبيع في المملكة العربية السعودية

- كسارات محجر للبيع في أستراليا

- الأجزاء الأساسية من كسارة الأوراق

- كسارة خام النيوبيوم

- تستخدم معدات الجرانيت الولايات المتحدة الأمريكية

- سعر كتلة الخرسانة غيانا

- الحديد تعدين خام طريقة معالجة

- آلة كسارة العشب مصر

- Reening Sand And Gravel Handbook

- Unki Mine Industrial Buying Process

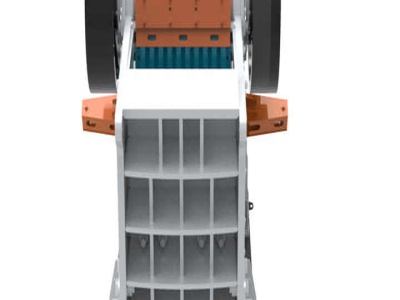

- Laboratory Equipment Jaw Crusher

- Bauxite Grinding Process Plant

- Stone Crusher Plant Au

- Crusher Plant Oregon

- Mill Design Ball Mills

- Sbm Jaw Crusher Animation

- Cina Re Rolligs Mills Hot

- Project Estimation Of Jaw Crusher

- Description Of Crushing Aggregate Romania

- Talc Production Line For Papermaking Additives

- Types Of Mining Machines Used In Tanzania

- Sand Mine In Glenwood City Wi

- Iral Classifier Hydrocyclone Mobile Cone Crusher