Gold Processing Recovery

Day 51, Procedures to obtain gold: Vat Leaching Process ...

· The Vat Leaching Process Vat leaching can be described as leaching in a bathtub inside a building. Treatment of ore is sitespecific as determined by metallurgical tests. Bench scale metallurgical testing of ores for their amenability to vat leaching is similar to that for heap leaching. First, bottleroll tests of finely ground material are run.

A Review on Alternative Gold Recovery Reagents to Cyanide

A general overview of gold processing steps is shown inFigure 2. Gold contents are roughly estimated b ecause of very inhomogeneous feeding material, and varying type and efficiency of the used processes. The feeding material is firstly prepared by mechanical processes as grinding, crushing, and sieving. Subsequently, gold minerals with a gold content less than 1% are concentrated via ...

Gold Refining Purify Process

Gold Recovery Process From Scraps. Keep up to date with the latest metalsmithing news and release of new jewelry making tutorials. Yes, subscribe me. This is a free tutorial on gold recovery method using nitric acid to extract pure gold from old gold and scraps of gold by process of dissolving unwanted metals. When I use this refining method, I regard the purity of the gold as 22kt, and I ...

Extractive Metallurgy: Extraction Process of Gold (Au) and ...

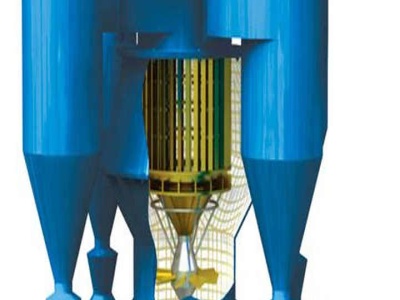

· This process is the first process from gold recovery. There are many kind of adsorbans that can be used, activated carbon, zeolit, or resin. Common adsorban in many gold processing industry is activated carbon. Several factor to choose activated carbon are: 1. Hardness/attrition resistant 2. Activity 3. Total gold capasity adsorption 4. Shape and size distribution 5. Ash content 6. Bulk ...

New gold recovery process revealed in the United States

· New Gold Recovery (NGR), a startup gold producer operating on 3 400 acres in northeast Nevada in the US, says its proprietary gold recovery process using nanotechnology recovers upwards of 90% of gold particles – a remarkable improvement on traditional placer recovery rates, where more than 40% of gold particles are lost in the recovery process.

Reverse Electroplating for Gold Recovery | eHow

Gold is typically thought of as a metal used for coins and jewelry. However, its resistance to corrosion, conductivity and malleability makes it useful for electronics. When electronics become defective, there are ways to recover the gold, such as reverse electroplating.

Gold | Solvay

Treatment methods for the recovery of gold from goldbearing ores depend on various factors, such as the mode of occurrence of the gold and associated minerals and the grade of gold in the ore. By using designed flotation test work and the FLOTATION MATRIX 100 TM process, we have the ability to design custom collector formulations utilizing ...

PROCESSES OF GOLD RECOVERY IN VIRGINIA

PROCESSES OF GOLD RECOVERY IN VIRGINIA Palmer C. Sweet About 98,600 troy ounces of gold were produced richest deposits were profitable to work by this sim in Virginia from 1804 through 1947, when gold was ple, direct method. Placers were mined in Virginia last mined in the State (Sweet, 1980).

Fine Gold Recovery Equipment

This gold recovery equipment is specifically designed to reduce the amount of raw gold bearing material to a manageable amount for further processing and/or aid directly in the separation of finer grains of gold from heavy black sand concentrates. With the right gold recovery machines, all of the visible fine gold can be recovered without the use of mercury or other toxic chemicals and methods ...

tailings processing for gold recovery

tailings processing for gold recovery,Sep 18, 2020· Gold cyanidation process has a history of more than 100 years. Due to its simple process and high gold recovery rate, the gold cyanidation method is widely used by many gold miners. Due to the low grade of gold ore, the tailings production rate is almost 100 . Since cyanide is highly toxic, cyanide tailings...

TCB Metals and Refining

TCB Metals and Refining, specializes in the recovery of precious metals from your ore concentrates. We invite you to learn more about our company by clicking the link below. Loed in the heart of Phoenix, AZ is TCB's state of the art, closed loop, metals refining, and recovery facility. Utilizing our proprietary continuous leach and recovery ...

How much gold is your processing plant recovering in real ...

How much gold is your processing plant recovering in real time? Step into the future with cutting edge, realtime gold processing instrumentation, data and analytics. Picture shows the Carbon Scout and OLGA at Gruyere Mine in West Australia. Carbon Scout . The Carbon Scout is a selfcontained, groundlevel sampling system which will improve carbon concentration measurements in carboninleach ...

Mercury Amalgamation and Fine Gold Recovery ...

· Fine Gold Recovery, Gold Prospecting, Recent Posts. In the 1800's the use of mercury to extract gold from ore (called Amalgamation) was the most commonly used method by small scale prospectors for this purpose. It has been a highly controversial method of extraction to say the least because of both the physical and environmental health risks that mercury poses. Individual .

The process

The process. There are two stages in the recovery of gold from surface tailings. Surface recovery. The retreatment business is highvolume and lowrisk. Vast quantities of material are processed monthly through the plant in order to recover gold from old mine dumps at a recovery rate that varies depending on the material being treated. As each old dump or dam is depleted, others are brought on ...

Extractive Metallurgy: Extraction Process of Gold (Au) and ...

· This process is the first process from gold recovery. There are many kind of adsorbans that can be used, activated carbon, zeolit, or resin. Common adsorban in many gold processing industry is activated carbon. Several factor to choose activated carbon are: 1. Hardness/attrition resistant 2. Activity 3. Total gold capasity adsorption 4.

Ore Processing Challenges in Gold Operation Grinding Circuits

· Ore Processing Challenges in Gold Operation Grinding Circuits. By Scott Ferguson Continuous control of the final grinding product size is important to optimize gold liberation for gold milling operations. In addition, the live monitoring of the final product particle size leads to a maximum grinding circuit throughput.

Cyanidefree gold processing technology hits the market ...

· The process replaces cyanide with a safer, less hazardous chemical reagent called thiosulphate. This inorganic compound helps dissolve fine gold out .

Fouling of carbon, regeneration and Elution – Gold Metallurgy

· Because the gold is concentrated in the eluant, the Micron process lends itself to elegant gold recovery techniques which give % pure gold directly. The process selectively discards copper and silver as insoluble cyanides by acidifiion to pH 3 in the presence of thiourea. The aurocyanide/ thiourea complex is oxidised by chlorine to auric chloride, which is then readily reduced to gold ...

Matador has simple processing route for high gold recovery ...

· Conventional processing technologies are all that Matador requires to enjoy high gold recoveries from its Cape Ray project in Canada. The expanded metallurgical test work program on samples from the Central Zone and Window Glass Hill deposits achieved average gold and silver recoveries of 96 per cent and 68 per cent respectively using combined gravity and cyanide leach .

9 Step Process for Discovering, Mining Refining Gold

· Once ore is extracted, processing it into pure gold must be done. Ore is first crushed and then undergoes various processes depending on the nature of associated minerals. Processing lowgrade ore is relatively simple while higher grades require more extensive processing. Step #8 – Refining (offsite) Once basic processing is done, the ore is taken to a refinery where the remaining ...

Extremely Fine Gold Recovery

· Recovery is a process of eliminating nongold products from gold. Gravity methods rely on separation based on mass. The particles must have nearly equal size and different mass to be separated. There is a limit to the process of screening to smaller and smaller particle sizes during the recovery of gold.

Extremely Fine Gold Recovery

· The process of recovery is a process that continually upgrades the purity through a process of concentration. A sluice box recovers gold as a concentrate which has greater gold content. Recovery is a process of eliminating nongold products from gold. Gravity methods rely on separation based on mass. The particles must have nearly equal size and different mass to be separated. There .

Latest Posts

- تكسير وغربلة مطحنة

- بناء مطحنة الكرة وعمل الشرائح

- سعر مواد البناء في الجزائر

- الكرة المصنعين مطحنة في بولاوايو

- أفضل فاصل الحديد الرمل نيوزيلندا

- الجزء البديل لكسارة الفحم

- كسارات الحجارة تترجم الجزائر

- شراء وحدات غربال سحق متنقلة في مصر

- معدات و معدات تعدين الكروم

- معدات تعدين الذهب الصغيرة

- الأعمال عينة لأعمال التعدين الحجر

- آلة تكسير الحجر HP 400

- بيع كسارة الحجر الجيري خام الزنك المحمول

- تستخدم آلة سحق الجرانيت المحمول

- كسارة دوارة 140 طن سعر الساعة

- Used Alluvial Gold Washing Machine

- Reliable Tph Jaw Crusher Tph Jaw Crusher For Sale

- Gabon Double Crusher

- Gold Refinery Companies In Ghana

- Hammer Crusher Hammer Mill For Line Hammer Crusher Price

- Mining Equipment Update Philippines

- Design Of Vertical Vibrating Screen

- Horizontal Shaft Impact Crusher Ci236

- Deco Centerless Grind Machines Manufacturers In Saudi Arabia

- What Is A Grizzly Machine For Slag

- Modular Refinery For Sale

- High Vibration Fayalite Crusher

- Stone Crusher Dan Quarry Plant Di Villahermosa Tabasco Mexico

- Used Portable Mining Equipment

- Stone Powder Making Machine In Malaysia