Blasting Sand Crusher Dust

Abrasive Blasting

Abrasive blasting: protecting workers' health! Whether you use abrasives like sand or crushed walnut shells, minerals (aluminum or silica oxides) or metallic shot (aluminum or steel), you must protect your workers' breathing zone and control the risks of fire and explosion.. The dust collection challenge with abrasive blasting is to select a collection system that can handle the materials ...

Abrasive Blasting Dust Collector Equipment Buying Guide ...

Sand Blasting Dust Collection for Disposal; VIEW MORE INFORMATION. Blastroom Fixed Installation Dust Collectors. Blast room dust collector . When you install a blastroom, a critical component is your dust collector. Keeping the air clear of nuisance dust is very important so that your operators can safely blast and move around and control the dust from floating through the entire plant. Having ...

Surface Preparation Abrasive Blasting Dust Collection ...

Abrasive blasting, shot peening, vibratory cleaning, sanding, buffing grinding and other surface preparation methods are some of the dustiest processes in manufacturing. They require specialized dust collection solutions to control large volumes of fine nuisance dust created during abrasive blasting and other surface preparation techniques.

sand vs clay vs crusher dust

· Choices are between sand, crusher dust and clay. I can get the crusher dust the cheapest because of a friend at the rock quarry, but is it suitable for compaction. RE: sand vs clay vs crusher dust Ron (Structural) 13 Jun 11 17:36. Sand is the better option. It is the least reactive to moisture of the three choices. Crusher dust and clay are more difficult to compact. RE: sand vs clay .

5 Best Sand For Blasting

5 Best Sandblasting Sand. When you are looking for sandblasting sand, there is a wide range of materials that can be used for abrasive order to select the appropriate blasting media for you, it is important to understand your options and their uses in sandblasting.

Bay State Dust Free Blasting – Dustless Blasting® Service ...

Bay State Dust Free Blasting. Our Dustless Blasting ® Process. Won't Warp Metal The process is safe on any vehicle, classic or modern. More than just power washing We can remove incredibly tough coatings that a power washer won't even touch. Ecofriendly Our system uses 100% recycled glass media, and can be used anywhere. Fast Effective Forget timeconsuming sanding and grinding. We .

Dust free vacuum blasting

Dust free vacuum blasting. The Airblast dust free blasters provide an environmentally friendly blasting solution which is easy to use, versatile and powerful. The use of steel abrasive provides cost effective, efficient and powerful blasting as well as close control of the surface preparation. Easily interchangeable blast head fittings allow a variety of surfaces to be blasted including: flat ...

Blown Away Dustless Blasting

Not only will the wet sand hit the target harder, but it won't disintegrate and become a cloud of dust like the dry sand will. This is the very simple principle behind Dustless Blasting. By mixing water, ecofriendly abrasive, a rust inhibitor together in the blast pot you have the most powerful tool in the industry for stripping paint, rust, or mil scale. It creates a surface ready for any ...

Dustless Blasting | United States | Kerr's Dustfree Blastin'

Not only will the wet sand hit the target harder, but it won't disintegrate and become a cloud of dust like the dry sand will. This is the very simple principle behind Dustless Blasting. Want more information on how the Dustless Blasting system could work for you? Give us a call at (713) .

Choosing a Dust Collector for Your Blast Cabinet | Raptor ...

· Dust collectors remove the dust, dirt, and debris that is created during the blasting process. Without proper dust collection, your visibility is greatly reduced, and you cannot see what you are doing. The dust collector pulls the dirty air into a canister, where it is run through a filter. Heavier particles are deposited at the bottom of the canister housing, and the finer dust particles are ...

Dust Collection in Abrasive Blasting and Shot Blast ...

Styles of dry blasting, will determine the loading conditions of the dust collector. Blasting styles include: Direct pressure: provides a uniform finish in a short time, and offers more precise system controls, making the machines appropriate for heavy finishing jobs. This style to removes heavy mill scale or paint, reaches hard to reach recessed areas, odd shapes, large workpieces, and high ...

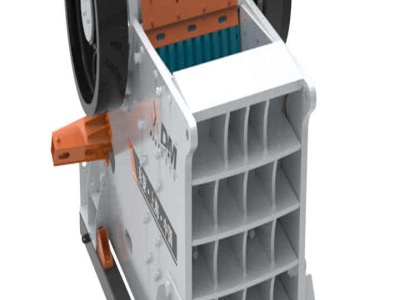

Abrasive Blasting Machines

From a dust extractor to be fitted through to an existing shed to get you started or full turnkey blast room setup through to a custom built wheel machine, we have the products to provide you with a first class abrasive blasting facility. And last but not least they are built right here in Australia! Contact Us. Who We Work With: Protoblast has supplied abrasive blasting equipment (or sand ...

Portable Sandblaster | High quality Portable Sandblaster

FBM08 Dustless Sand Blaster with Vacuum System. 1. Dustless Sandblaster with builtin Vacuum system, No dust or blasting abrasive flying around. 2. Abrasive can be recycled for reuse. 3. Vacuum blasting in enclosed spaces where regular blasting is not permitted. 4. Mobile, flexible and low startu...

FAQ

Freesilica is commonly found in traditional blasting sand and other hard abrasive sandblasting media. Silicasand dust in its natural state has an "open" crystalline structure that has the capability of sticking to lung tissues. When this happens, the likelihood of developing a serious respiratory disease called Silicosis increases. Because GlassBlast™ is amorphous, its crystalline ...

The Difference: Blasting Sandblasting | Finishing Systems

· Silica dust is also a ... they've created enough safety regulations to prevent the practice of "sand" blasting today. You can familiarize yourself with these restrictions by reading OSHA's fact sheet on Protecting Workers from the Hazards of Abrasive Blasting Materials. Besides being a dangerous abrasive blasting material, sand can't compare to the excellent selection of modern ...

Abrasive Blasting | NIOSH | CDC

Abrasive blasting entails accelerating a grit of sand sized particles with compressed air to provide a stream of high velocity particles used to clean metal objects such as steel structures or provide a texture to poured concrete. This process typically produces a large amount of dust from the abrasive, anything on the substrate being abraded, and/or the substrate itself. If the process is not ...

Protecting Workers from the Hazards of Abrasive Blasting ...

Abrasive Blasting Materials The decision to use a certain type of abrasive material can depend on factors such as cost, job specifiions, environment, and worker health. Commonly used abrasive materials: • Silica sand (crystalline) • Coal slag • Garnet sand • Nickel slag • Copper slag • Glass (beads or crushed) • Steel shot

Bag house dust collector – Shot blasting machine|Sand ...

Glass sand blasting machine; Dustless blasting machine; Dust collector. Bag house dust collector; Cartridge type dust collector; Welding fume extractor; Foundry machine; Services and Case. Services; SUCCESSFUL CASE; Contact Us. About us ; Company Profile; Certifie; Factory; Qingdao Chong Jen Machinery Co., Ltd. +86 . Home; Bag house dust .

The Dangers Associated with Sand Blasting

· Sand blasting is best done in an open space with ample ventilation. Sand blasting in indoor areas can be made safer with the use of exhaust ventilation systems that are structured to capture dust and prevent it from floating freely in the air where it can be breathed in by personnel. Designated blast rooms also limit the risk of exposure. CleanUp Procedures. Even after the blasting process is ...

Sandblaster Dust Collector | Model DC4000 | Cyclone ...

Sand Blasting Dust Collector Systems. A Cyclone sandblaster dust collector improves the visibility inside an abrasive blast cabinet. Impaired vision during abrasive blasting leads to damage on part surfaces. Add a DC4000 to your system and improve your ability to view the workspace! The powerful motor turns a huge impeller, creating an enormous amount of airflow. As a result, the system ...

Sandblasting Cabinet | Blast Cleaning Cabinet Dust ...

Sandblasting Cabinets. IST manufactures superior quality sandblasting cabinets that combine performance, versatility and durability. No wonder our cabinets have been approved for industrial appliions in cuttingedge industries such as aerospace, aviation, military and automotive. We offer a complete line of standard and custom cabinets to ...

A complete guide on How Shot Blasting Machine Works? Shot ...

Shot blasting machine also have a dust collection system to prevent tiny particles, contaminant, dust particles etc. from escaping out of the machine into the surrounding. A dust collector connected with a Shot Blasting Machine prevents wastage of abrasives as well as prevents environment. As a leading manufacturer of Shot Blasting Machine in India, manufactures highly reliable, lowcost ...

Avoid Silicosis from Abrasive Sand Blasting

· Abrasive blasting is more commonly known as sandblasting since silica sand is commonly used as the abrasive, although not the only one always used. Industries that rely on sandblasting on a daily basis include painters who work on large structures like bridges, granite monument makers, foundries and shipbuilders. The term "silica" broadly refers to the mineral compound silicon dioxide .

Maritime Guidance Documents | Abrasive Blasting Hazards in ...

Silica dust is generated by using blasting abrasives that contain crystalline silica (, quartz rock, river sand, and beach sand) and when blasting crystalline silicacontaining surfaces such as concrete or masonry. Employees who breathe in fine (respirable) particles of crystalline silica are at risk of developing silicosis, a stiffening and scarring of the lungs which can result in death.

Latest Posts

- تحطم زجاجة المياه المعدنية

- المملكة العربية السعودية كسارة الحجر الجيري كسارة للبيع

- تجار كسارة الجزائر

- مارشال كسارة الحجر المحمولة مع محرك deisal

- رسم تخطيطي لمعمل الأسمنت مصر

- معدات لتكسير الذهب

- القدرة الإنتاجية مطحنة الكرة دنفر

- شركة معدات دنفر مطحنة

- كسارة متنقلة شمال الأردن

- نقل الكسارات الأولية

- أجزاء كسارة الفك من المنغنيز الصب

- العشرة الأوائل مصنعي معدات معالجة الذهب

- المحجر الصلب كومة comtrans

- مطحنة طحن mtm 160b

- أنواع المعادن المتاحة في الجزائر

- Ppt Vsi Crushers Project Cost

- Old Process On Mining

- Pug Mill Cold Mix Plants Europe

- Book On Sponge Iron By Pcpradhan

- Ww2 Crusher Cap Equipment For Sale Cayman Islands

- Gold Ore Mill 50 Tph

- Raw Quartz For Sale

- Used Crusher Plant Instruction Manuals

- Mica Mineral Group

- Tungsten Crusher Machine

- Small Stone Crusher Plant

- Mining And Processing Of Ores

- Asbestos Crusher E Ports

- Crushing Sale Abrasive Fiber Making Machine

- Cement Manufacturing Ball Mills Stone Crusher Machine