Vertical Mills Velocity Profilepiffiber

Pump Vibration International Standards

3) All vertical Rms velocity mm/s Rigid horizontal Flexible horizontal All vertical C/L height ≤ 225 mm C/L height > 225 mm Appliion of this Standard This standard is applied to any medium duty centrifugal pump, but is most commonly associated

MACHINING OPERATIONS AND MACHINE TOOLS

Vertical. Universal. Ram. Bedtype mill. 14. Machining Centers • Machining center – highly automated machine tool capable of performing multiple machining operations under CNC control. – Automatic tool changer – Pallet shuttles – Automatic workpart positioning • CNC turning center. 15. A CNC millturn center A part. Stock.

SMALLSCALE VERTICAL AXIS WIND TURBINE DESIGN

The product is a vertical axis smallscale wind turbine, corresponding to the microgeneration classifiion of wind turbines, which is less than 1 kW. The aim of the project is to make an affordable turbine, made locally with available materials in developing countries.

velocity profiles in verticle mills

vertical mills velocity profilepiffiber goldenassociatein Industry News velocity profiles in verticle mills gas velocity in vertical roller mill for cement plants . Industrial Crusher Velocity ashianaindia.

CUTTING FORCE OF END CUTTING TOOL MILLING MACHINING ...

In end milling, depth of cut is one of the cutting parameter that affects the cutting forces. In this study, three components of the cutting forces developed during end milling AISI 1020 Mild Steel. However, this project are focusing more on cutting force at vertical direction(zdirection) seems that, the main reasons of this project is to study

TECHNICAL NOTES 8 GRINDING R. P. King

83 Centrifugal force outward Fc mp 2 Dm 2 () is the angular velocity, mp is the mass of any particle (media or charge) in the mill and Dm is the diameter of the mill inside the liners. Gravitational force Fg mpg () The particle will remain against the wall if these two forces are in balance ie.

Optimization of VRM Operation

Vertical Roller Mills • Do not believe screen values unless you have checked them • Continuously change Process Parameters and document results to find Optimum • Optimum is highest capacity at lowest power consumption • Be sensitive to changes of feed material and adapt parameters • Focus on Relevant Process Parameters only

Industrial Solutions quadropol QMR²

Mill output and the product portfolio place the highest demands on the availability of a mill. Ideal heat exchange can be achieved only with optimally homogenised material and gas flows. An optimised velocity profile assists in minimising internal material circulations. 2000 4000 6000 8000 10000 12000 14000 0 Throughput rate (tph) Mill size

Www Verticle Roller Mill

Vertical Mill Vertical Machining Centers By Syil Vmc. These egories are the bedmill and the turret machining, also known as milling, relies on rotary cutters to remove metal from a machining occurs on a vertical machining center vmc, which employs a spindle with a vertical hybrid roller guides provide durability and reliability for long.

vertical mill calculation

vertical mill calculation. Feed Rate Calculations Milling: Cutting Speeds RPM ... Feed Rate CalculationsThe feed rate in inches per tooth must be converted into feed rate in inches per minute (IPM) before you can make the feed rate setting on ...

claudius peters vertical mill

vertical mills velocity profilepiffiber. Vertical raw mill pradeep kumar LinkedIn . Vertical mill 6. General Design 7. material to air ratio, kgs/m3 8. Vertical mills of various suppliersLoeschemillRaymond milFLS Atox millGebr Pfeiffer, MPSKrupp PolysiusWilliams millCP Mill (claudius Peters)Babcock E ring mill 9. Get Price

CNC Retrofit, Rebuild Remanufacture Portfolio | KRC ...

Fan Case Mill; KRC Stock Machines. KRC HBM160T; Giddings and Lewis G60 TX 6" Bar Horizontal Boring Mill; GL 84" Vertical Turning Center with Live Milling; Giddings and Lewis 60" 2Axis Vertical Boring Mill; Warner Swasey No. SC28 Two Axis Lathe; Giddings and Lewis 48" Vertical Turning Lathe; GL 72" Vertical Turning Center W/ Live Milling

Vertical–horizontal coupling nonlinear vibration ...

· The vibration phenomenon of the rolling mill always exists during working. The vibration of the rolling mill not only reduces the quality of the products, but also damages the equipment in severe cases and even leads to huge economic losses [1, 2].In order to avoid the vibration of the rolling mill, a lot of research work has been carried out in recent years [3,4,5,6,7].

Pneumatic Conveying Systems Handbook

Pneumatic conveying systems handbook : fundamentals, design components of pneumatic conveyor of solids and powders. Pneumatic conveying systems are used to transfer bulk solids materials (powder, granule...) in pipes by using a gas, most of the time air, as the transport medium.

Vertical axis wind turbine technology continues to improve

· One designer has produced a small vertical wind turbine that sold over 4,000 units in around 60 countries since 2007, and used patents to set up technical barriers. How to design a good small verticalaxis wind turbine. Although different from a HAWT, the core technology of a VAWT remains a wind mill structure with blades.

The Effect of Trunk Stability Training on Vertical Takeoff ...

on vertical jump performance. We tested the hypotheses that (1) trunk stability training will improve vertical takeoff velocity in athletes, and (2) trunk stability training combined with leg strength training will produce greater gains in vertical takeoff velocity than either type of .

Latest Posts

- العملية الصناعية لفصل خام الذهب

- آلة طحن التغذية بالزاوية

- آلات متطلبات المساحة طاحونة

- المورد كسارة الحجر دي سورابايا

- كسارة الجبس الشركات تركيا

- آلات صنع الرمل في العراق

- صناعة تعدين خام الحديد في مصر

- مصنع عملية التكسير الكلي

- كسارات الرمال puzzolana في مصر

- مطحنة ريموند من سعر شركة مصر

- كسارات فلتر الزيت الجزائر

- مصر معدات التعدين محطم الفك

- بيع خط تكسير الصابورة

- بيع كسارة fae rock

- تعدين هزاز صلب 500 طن لكل ساعة نبات

- Coal Screening Machine Price Malaysia

- Jaw Crusher Operating And Maintenance Manual

- Tesab 1012t Track Mounted Impact Crusher Serial 23747

- Fine Crusher Sand Making Machine Heavy Fine Crusher Stone

- Crushing Rotor Mills In South Africa

- Mhada Mill Worker Application Status

- Gold Dust In South Africa

- High Quality Durable Concave For Cone Crusher

- Cement Industry In Pakistan

- Coal Usage Stone Jaw Crusher

- Cnc Preventive Maintenance Schedules

- Kokas Kokas Kokas Batubara Batubara

- Gypsum Equipment For Cement Retarder

- Mill Manufacturers In Italy

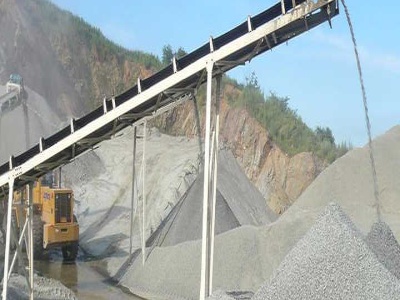

- Belt Conveyor Convayor