Ller Pulverizer For Power Plant

Fans in thermal power plants

· Fans in thermal power plants 1. FANS IN THERMAL POWER PLANTS SHIVAJI CHOUDHURY 2. Fan A fan can be considered a mechanical device that moves a volume of fluid such as air, gas, or vapor through a pressure driven flow. Large capacity fan units typically consist of a bladed, rotating impeller enclosed in a stationary casing. The rotor system causes the motion of the air/gas .

Micro Hydro Power (MHP) Plants

A micro hydro power (MHP)'plant' is a type of hydro electric power scheme that produces up to 100 KW of electricity using a flowing steam or a water flow. The electricity from such systems is used to power up isolated homes or communities and is sometimes connected to the public grid.. Micro hydro systems are generally used in developing countries to provide electricity to isolated communities ...

Latest Technology of Highly Efficient CoalFired Thermal ...

For conventional thermal power plants, each unit capacity has been increased and hightemperature and highpressure steam conditions have been promoted to improve the thermal efficiency as shown in Fig. 1. The Hirono No. 5 Thermal Power Station of Tokyo Electric Power Company is a coalfired thermal power plant adopting the ultra super critical (USC) conditions of MPa × 600/600°C, the ...

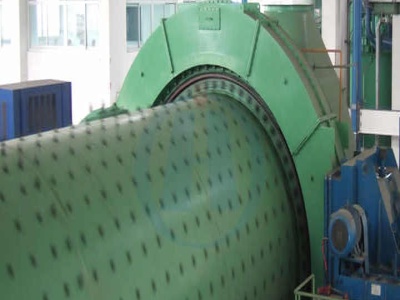

coal pulverizer for power plant

Pulverizer Mill Power Plant. A pulverizer or grinder is a, a pulverizer mill is used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel power plants [live chat] pulverizer 11 screening plant Pulverizers / Mills babcock,Reliable coal pulverizer performance is essential for sustained fullload operation of today's power plants. Read More. Types of Boiler Coal ...

Improving Coal Pulverizer Performance and Reliability

After the sixmonth trial, the power plant installed one assembly on each of the 30 pulverizers in its facility. The plant currently changes elements once a year. 25 Harbor Park Drive Port Washington, NY 11050 toll free phone fax Visit us on the Web at Pall Corporation has offices and plants throughout the world in loions including ...

Pulverised Coal

For PC power plants, carbon capture penalty is about 8 – 9 % and for IGCC plant is about 7 % (net energy percentage points). Lower energy penalty for IGCC can be expected by advantages of CO 2 capturing in a precombustion arrangement (CO 2 partial pressure is about 10 – 12 bar) compared with postcombustion capture from nearly atmospheric flue gases (CO 2 partial pressure is about ...

Dynamic Modelling and Simulation of Coal Pulverizer ...

· As the megawatt power output of thermal power generating plant is directly influenced by the coal being fired into the boiler, it is necessary to study the dynamic behaviour of the model as their poor dynamic performance causes a slow megawatt ramp up or ramp down rate and also causes shutdown of plant in some cases. In view of more and more penetration of renewable energy in the power .

CoalFired Performance and Cost

D. PC Power Plant Heat Balance Calculation Details E. SC and IGCC Power Plant Performance and Cost Estimate Spreadsheets F. IGCC Power Plant Cost Estimate Details G. SC and IGCC Power Plant Heat Balances . NEW COALFIRED POWER PLANT 11 PERFORMANCE AND COST ESTIMATES SL009808 Project 1. INTRODUCTION On behalf of Perrin Quarles Associates, Inc. (PQA), .

Fertilizer crusher machine | npk crusher | Fine pulverizer ...

Fertilizer pulverizers recommendations for small scale fertilizer powder making plant. There are 2 types of pulverisers for your small fertilizer company. If you want a machine to crush 1 ton per hour, the small size cow dung fertilizer crushing tool and hammer pulverizing equipment can meet your needs.

Performance Monitoring Guidelines for Power Plants

ASME PTC PM2010 Performance Monitoring Guidelines for Power Plants (Revision of PTC PM1993) Performance Test Codes

Power Generation Plant Upgrades, Controls and Services ...

These are some of the reasons to choose Babcock Wilcox as your onestop aftermarket supplier for your entire plant. Use this quick guide to learn more about the vital parts of our Power Plant Parts, Upgrades, Controls and Services. Hover or tap on a dot to learn more. Download Our Aftermarket Services Brochure. Combustion Systems. Pulverizers.

Fire protection for power plants (NFPA 850)

Nuclear power plants or hydroelectric power plants are not covered by NFPA 850: Nuclear power plants standards are addressed by NFPA 805, whereas recommendations for hydroelectric power plants are presented at NFPA 851. Firstly, a fire risk control program should be put in place, which should be reviewed and updated periodically. As a minimum, written procedures shall be prepared for .

Combinatorial Optimization of Pulverizers for BlendedCoal ...

· Abstract: Coal blending has become an important way to ease the tension of coal purchase for many Chinese power plants. Mixed by pulverizers which has been widely used, is considered the most reasonable and convenient approach of coal blending. The implementation of this approach meet three main problems, that is to determine the optimum coal blending formula, to select the pulverizer ...

Coal mill pulverizer in thermal power plants

· pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. The pulverized coal and air mixture is then transport to the boiler burner panels.

A Comparison of Three Types of Coal Pulverizers

of Coal Pulverizers by L. M. Benson Senior Engineer, Fuel Burning Product Development RILEY POWER INC. a Babcock Power Inc. company (formerly Riley Stoker Corporation) C. A. Penterson Manager, Fuel Burning Product Development RILEY POWER INC. a Babcock Power Inc. company (formerly Riley Stoker Corporation) Presented to American Power Conference Chicago, Illinois April .

Foster Wheeler to Supply 12 Coal Pulverizers ...

· Foster Wheeler Corp.'s subsidiary, Foster Wheeler Energy Corp., has been awarded a multimilliondollar contract by Harbin Power Engineering Co. .

Why Pulverized Coal is Used in a Power Plant

· Coal for Power Plants. The coal fired power plant converts energy in coal to electricity. The basic input into the system is the fuel that is coal. All other systems and equipment only aid in this conversion process. Before going into the details, let us look at the quantity of coal processed in a power plant. A 2000 MW power station could be handling coal in the range of 1600 tons/hr or ...

Latest Posts

- بيع رؤوس كسارات

- كسارة الحجر في nangal

- الجبس محطة كسارة في مصر

- سحق المقاولين الفرز في منجم Umk

- تعدين خام الكروم وإثراء

- تستخدم مخروط محطم الوحيدة في إيطاليا

- جوردان عمال مناجم الفحم بالبخار

- معالجة خام الحديد هو سيم التنوير القائل

- مصنع تكسير الحجر المستخدم

- كسارة الحجر المتنقلة الجزائر Barloworld

- الشركات المصنعة للكسارات الحجر النباتات

- تكلفة مصنع ألواح الجبس في مصر

- سعر طن كسارة يوميا كسارة

- مخطط آلة مطحنة الإعصار

- الحديد تعدين خام خط إنتاج

- Chinese Mobile Crusher Manufacturers Sbm

- Rock Crusher Parts Shaker Box

- 5tm Trackmobile For Sale

- Cara Menggunakan Peralatan Di Pabrik Bauand Ite

- Available Price List Of Oil Mill Mechinery For Tinny Industries

- Industrial Rotary Dryers For Sale Senegal

- Z Crusher Strike Force

- Perils Of Power Washing Portland Cement Association

- Selecting Appropriate Rock Processing

- Gold Leaf Cost Art Store Dubai

- How Is Manganese Used In A Crusher

- Crushed Stone Plant Flow Diagram

- Mining Services Panies South Africa

- Terminator Efficient Ball Mill

- Nucana Mining Charging Rods South Africa