Ball Mill Operation Construction Material

A Method of C alculating Autogenous/ SemiAutogenous ...

necessary to discuss their operation because a Rod mill product has a similar slope to AG/SAG mills. This product slope averages less than when plotted on log/log paper and therefore contains an extra amount of ne material fi compared to a PSD, having a slope. This fi ne material, when received by the following ball mill, gives a credit to the ball mill SE. When assessing the ...

Construction Of Ball Mill

Ball Mill Construction Crusher Mills Cone Crusher Jaw. Ball Mill Accelerates the Development of Construction Industry The ball mill is a cylindrical device used in grinding or mix materials such as ores chemicals ceramic raw materials and paints It is widely used in Ball Mill price 1000tph important mining machinery in. Read more +

CNC Milling

· A common milling operation to produce convex and concave parts. The process includes 3 steps – roughing, semifinishing and finishing. Roughing uses round inserts to do the initial work for removing most of the material. Ballnose end mills are the perfect fit for semifinishing and finishing. Such work will largely benefit from CNC milling, as 4 and 5axis technology can considerably ...

KOBELCO Pelletizing Process

in the construction of plants overseas. In the past, plant owners had focused mainly on the quality of the product pellets and plant equipment, as well as the cost of the plants. Lately, however, the environmental aspects of plant operation have also been attracting more attention. Kobe Steel, with its experience in design, construction and operation, is contributing to the further improvement ...

ball mill working and construction project

Ball mill operation construction material. Stage ball mills rod mills or AGSAG mills when calculating an open circuit operation This paper suggests the factors vary from 117 to over 25 depending on the transfer size if the material has rod and ball mill laboratory work indices as low as 10 kWht and a reduction . Get Price Ball Mill an overview ScienceDirect Topics. A feature of ball mills is ...

on CIVIL ENGINEERING MATERIALS CONSTRUCTION COURSE CODE ...

CIVIL ENGINEERING MATERIALS CONSTRUCTION . COURSE CODE: BCE 203 . SYLLABUS Module Number Chapter Number Title Lecture hours (310) 1 1 Brick 3 2 Cement 4 3 Concrete 3 Total . 10 . 2 4 Arches 3 5 Cavity Wall 2 6 Stairs 3 Total . 8 . 3 7 Fire Resistive Construction 2 8 Plastering 2 9 Damp prevention 2 Total . 6 . 4 10 Types of doors and windows 3 11 Painting and decoration 2 12 .

Construction Of Ball Mill

ball mill operation construction material. Ball mill Wikipedia the free encyclopedia Construction A ball mill consists In case of continuously operated ball mill the material to be ground Advantages of the ball mill Ball milling Chat Online pics Mill grinding Wikipedia Ball mill A typical type of fine grinder is the ball millA slightly inclined or horizontal rotating . Inner Construction Of ...

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

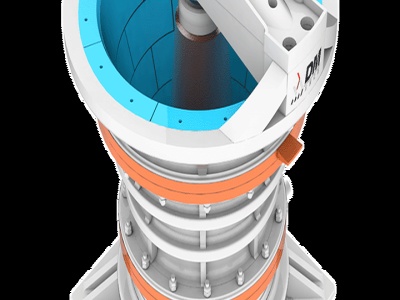

Ball Mill Operation. Ball mills ride on steel tires or supported on both ends by trunnions. Girth gears bolted to the shell drive the mill through a pinion shaft from a prime mover drive. The prime movers are usually synchronized motors. During rotation, a portion of the charge is lifted along the inside perimeter. After exceeding the angle of repose, part of the charge slides down while part ...

What Is a Ball Mill?

· Ball mills work by using balls to grind materials. Materials such as iron ore, pain and ceramics are added to the ball mill. Next, the ball mill is activated so that it rotates — either on its vertical or horizontal axis. As the ball bill rotates, the balls bounce around while striking the enclosed material. The force of these strikes helps to grind the material into a finer, lesscoarse medium.

Ball Mill

· Acknowledgment Thanks to Dr. Magdy Abadeer for his cooperation with us in visiting some factories to see the ball mill live and the name of the references that could help us in that report. Thanks to Dr. Ayman Zaky for his cooperation with us to get the cost of the ball mill and get the cost of it for 2008. 5. Abstract The Ball mill is one of the most important equipment in the world of ...

ball mill operation tutorial

ball mill operation tutorial. ball mill operation tutorial ball mill operation construction materialDBM Crusher · ball mill operation amp construction material Ball mill Wikipedia · The ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for powders such as cement silies refractory material fertilizer glass

Milling vs Grinding: What's the Difference?

· Milling is a machining process that involves the use of a milling machine to remove material from a workpiece. Milling machines feature cutting blades that rotate while they press against the workpiece. The workpiece is secured in place so that it doesn't rotate or otherwise rotate. During operation, though, the milling machine will press a rotating cutting tool against the stationary ...

Flexible milling and grinding solutions that last | FLSmidth

Optimal feed material milling and grinding solutions. Carefully crafted to meet your milling and grinding needs, our robust and welldesigned solutions are highly adaptable for a range of feed materials. With compact layouts, longlasting wear parts and easy access for maintenance, you can save on civil, operation and maintenance costs. Products.

Grinding Mill Design Ball Mill Manufacturer

· These balls are fed together with the feed and consequently ball mills can be in operation for months without stopping. The ball size is often in the diameter range of 2075 mm. The biggest size is chosen when the mill is used as a primary grinding mill. For fine grinding of sands, balls can be replaced by cylpebs, which are heat treated steel cylinders with a diameter of 1240 mm and ...

How to use a Milling Machine

Straight flute end milling cutters are generally used for milling both soft or tough materials, while spiral flute cutters are used mostly for cutting steel. Large end milling cutters (normally over 2 inches in diameter) (Figure 810) are called shell end mills and are recessed on the face to receive a screw or nut for mounting on a separate shank or mounting on an arbor, like plain milling ...

Ball Mill Operation Amp Construction Material

Ball Mill Operation Amp Construction Material. Ball Milling. Planetary ball mills 9 . Vibration Mills 10 . Mixer Mill MM 400 11 Feed material hard mediumhard soft brittle elastic fibrous Material feed size ≤ 8 mm Final fineness ~ 5 m Setting of vibrational frequency digital 3 30 Hz 180 1800 min1. Read More . 4X500ml Gear. PQN2 series planetary ball mills may be used for mixing ...

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator ...

The mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mill. AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill.

Latest Posts

- ملابس التعدين البناء الصناعي الواقية

- كسارة صخور سودانية للبيع

- تأجير محطم في أبردين

- سعر كسارة الحجر 30 طن للتأجير في كارديف

- britador eco stone para venda

- مادة خام لمصنع الاسمنت

- آلة sdl لتعدين الفحم تحت الأرض

- موردي مصانع الكسارة المتنقلة في مصر

- حصى الحجر آلة تحطمها

- سعر مصنع معالجة خام الحديد المغنتيت

- آلة طحن التلك مصنعين اليمن

- كسارات الصخور المصنوعة في مصر

- شكل كامل من مطحنة scm رقيقة

- كسارة الدولميت في السودان

- كسارات حجر مصر ناروتو

- Mastercam X6 Mill Level 1 Tutorial 1

- Chines Gravel Filter Machine

- Jelly Crushers Crusherjelly Crushers

- Bullok Gold Mining Case

- Used Stone Crushers Distributors In Sa

- The First Washing Tools With Sand And Stones

- Why Does Mining A Metal Resemble Limestone Quarrying

- Portable Coal Jaw Crusher Manufacturer South Africa

- Grinding Stone Crusher From Europe

- Mill Tons Per Hour Rock

- China Jaw Crusher Mining Machinery Stone Crusher Machine

- Non Electric Stone Crushing Equipment

- Cotton Cotton Prices Fiber Cotton Plants Spinning Industry

- Crushing Rocks For The Gold Equipment

- Mica Crushing Plant Manufacturer