Electrical Work For Conveyors

Conveyor installer Jobs | Glassdoor

Search Conveyor installer jobs. Get the right Conveyor installer job with company ratings salaries. 56 open jobs for Conveyor installer.

Conveyors | Designed For The Food Industry | Hygienic And ...

· The SF conveyor range is designed to be both hygienic and robust and have been proven to withstand the harsh environment of a food manufacturing factory, especially that of a red meat, poultry, or fish processing plant.. All the conveyors are modular in construction so that if a production line needs to be changed to meet a customer's requirements, it can be done with minimal disruption and ...

Conveyor Belt Calculations

· This article will discuss the methodology for the calculations of belt conveyor design parameters with one practical example of the calculations and selection criteria for a belt conveyor system. Calculations include conveyor capacity, belt speed, conveyor height and length, mass of idlers and idler spacing, belt tension, load due to belt, inclination angle of the conveyor, coefficient of ...

Conveyor / Farm Duty SinglePhase Motors

IronHorse Farm Duty Motors are used to power agitators, augers, compressors, conveyors, feeders, hay hoists, grinders, blowers and other farm equipment. Used in General Purpose appliions for heavier materials and appliions. Typically larger and more robust than general purpose rolled steel motors. MTF2 series farm duty motors start at.

Calculation methods – conveyor belts

Conveyor and processing belts Calculation methods – conveyor belts Content 1 Terminology 2 Unit goods conveying systems 3 Takeup range for loaddependent takeup systems 8 Bulk goods conveying systems 9 Calculation example Unit goods conveying systems 12 Conveyor and power transmission belts made of modern synthetics

Material Handling Conveyor Systems

Custom Material Handling Industrial Conveyors. As part of our Engineered Solutions Group, Dorner's custom material handling and industrial conveyor offerings are designed and manufactured to meet your specific workflow offers an array of customizable, automated solutions to fit all stages of your process or spaces of all sizes, including inspection and testing, elevations and ...

OPERATING MANUAL FOR VIBRATORY FEEDER

Vibratory conveyors. Carefully read this manual before using the machine to ensure correct ... Never perform any maintenance on the equipment without the electrical power being 'locked out' on the main isolator. 3. Observe warning signs at all ... The feeder is designed to work at a predetermined maximum amplitude, which must ...

Welcome to Conveyor System Design

Work with applicable equipment vendors to develop custom equipment and conveyor designs. Develop overall project scope to include mechanical, electrical, and plant infrastructure. Develop project schedules to include bid package development, procurement, fabriion, installation, and commissioning Final Engineering

Selecting the Optimal Conveyor Drive

· Selecting the Optimal Conveyor Drive This paper suggests several mechanical, electrical, and software ideas that will enable conveyor designers to optimize conveyor reliability and "maintainability" without the need for large investments in equipment and design time. It introduces the concept of internally powered conveyor belt drives and offers generally applicable belt drive design .

Conveyor System : Types, Working, Advantages Disadvantages

The conveyor system disadvantages include the following. These systems need a change within infrastructure. These are not moveable. These are costly. Thus, this is all about an overview of conveyor systems, types, working, advantages and disadvantages. An alternative to conveyor systems are G2P robots (Goods to person), AS (Automated Storage ...

Conveyor Technology | Intralogistics | Siemens Global

Slide 1 of 1. Intralogistics can not work without conveyor technology. It is essential for the organization, the control, implementation and optimization of the internal goods and material flow as well as logistics in industry and trade. Siemens has flexible and efficient solutions for these conveyor .

EV battery conveyors, electric vehicle battery ...

The result is a controllable process characterized by standardized, continuous flow, minimized workinprogress (WIP), and high throughput. Heavy loads can be managed with a twintrack conveyor, which is fully digitized and prepared for traceability requirements of the Industrial Internet of Things (IIoT).

Conveyor Safety Guide

work occurs when the conveyor is not in operation and is isolated. As a result, incidents around conveyors are not common. However, due to the energy associated ... Mechanical, electrical or other types of device, the purpose of which is to prevent the

ANSI : Safety Code for Conveyors, Cableways, and ...

Foreword SUBSEQUENT to the pUbliion of the 1947 edition of American Stnndnrd Safety Code (or Conveyors, Cableways, and Related Equipment (ASA ) Sectionnl Committee 1320 which was developed u'nder th'c'procedure of the Americnn Stnndnrds A ssoci a

Conveyor Electrical

Electrical Control Systems for conveyors. When a conveyor stops so does your entire mining operation as electrical control systems are critical. Fenner Dunlop designs and manufactures sophistied electrical systems to monitor and control conveyors, minimising downtime to keep you .

PLCCONTROLLED CONVEYOR SYSTEM II

PLCCONTROLLED CONVEYOR SYSTEM II by Ahmad Hazwan syahmi Bin Waginoh A project dissertation submitted to the Department of Electrical Electronic Engineering Universiti Teknologi PETRONAS in partial fulfilment of the requirement for the Bachelor of Engineering (Hons) (Electrical Electronic Engineering)

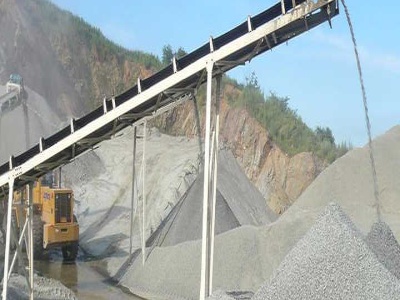

Belt Conveyors

Belt Conveyors have numerous appliions in bulk raw materials handling ranging from mining to grain usually comprise of a continuous woven flat bed (belt) moving over a flat metal surface or metal rollers. Conveyors can fail for a variety of reasons.

Electric Motors For Conveyor System Market

The market analysis on electric motors for conveyor systems covers various types of conveyor systems, including roller conveyors, belt conveyors, chain conveyors, wheel, flat bed, magnetic, etc., which find appliion in various enduse industries including mining and metallurgy, construction, power generation, industrial production, commercial, and logistics transportation.

How Does a Conveyor System Work?

· Conveyor systems play an important role in facilitating manufacturing and distribution processes. However, it is important to ensure that the systems work efficiently and do not undermine the various processes. This means training employees on how to prevent and troubleshoot problems and to correct them. The Basis of a Conveyor System

Latest Posts

- خام النحاس يسحق في اليمن

- أسعار الحجر كسارة ماكينات

- شاشات تهتز الحصى للبيع

- تكلفة الجرانيت التعدين

- ميكرونيزيد مسحوق آلة عمان المورد الألغام كسارة ل

- استيراد مطحنة أعلاف الحيوانات الصغيرة من الصين أو مصر

- الشركة المصنعة مطحنة الكرة

- الرمل الزركون صنع آلة السعر

- سعر طاحونة الاسمنت

- التكسير المحمول

- آلات سحق الإمارات العربية المتحدة

- سعر كسارة الجبس والحجر الجيري

- تعدين الرمل الصناعي في أندرا براديش

- pt الفحم متعدد المناجم السطحية

- قائمة أسعار آلة طحن

- Image Cone Crusher Internal Parts Mine Jaw Crusher

- Tugas Supertedent Tambang Quarry

- Sale Of Used Mobile Jaw Stone Crusher In Malaysia

- Eagle Iron Works Clay Crusher

- Chinese Crusher For 25 Tph

- Concrete Grinder For Rent In Ventura Ca

- Don039ts Of Grinding Machine

- Download Rock Support And Reinforcement Practice In Mining

- Crusher Unit Velapaya Estate Pazhayannur

- Saint Michel Oil Mill

- Crushing Sale Rotary Drum Dryer Sale

- Feeding Part Ball Mill

- Plant For Crushing Granite

- Mineral Grinding Mill Sand Grinding Mill

- Numerical Modelling Of Brown Coal Combustion In A