Grinding Technology In Cement Making

Plastic Concrete: Building Bricks Made From Landfill Waste

Sep 21, 2009 · By grinding up landfillbound plastic and mixing it with portland cement, Miller was able to create a material just as strong as traditional concrete made with mined aggregate.

Angle Grinder Uses and the Influence of Cordless Technology

· Angle Grinder Uses are Based on Size and Trade. Angle grinders are segmented into three major classes by wheel diameter: small at 41/2 to 5 inches, medium at 6 inches, and large at 7 to 9 inches. The motor size increases in these classes from 11amp, to 13amp, to 15amp. Cordless grinders simply ask more from their battery.

Back To The Grind: World Cement Grinding QA with Fives

Apr 15, 2021 · Therefore, limiting grinding power demand is a major industry focus. The endproduct evolution is another key issue to address, with respect to the expansion of the cement additives range and cement/clinker ratio, as well as the emergence of ultrafine products in the cement industry.

CO2 Cement Production

Cement is produced in capitalintensive plants often loed near limestone (CaCO3) quarries. The number of plants is generally low (less than 100) and the plants are easy to loe and monitor, making it highly feasible for . Good Practice Guidance and Uncertainty Management in .

Polished Concrete Process

The next steps involve fine grinding of the concrete surface using diamond abrasives embedded in a plastic or resin matrix. Crews use everfiner grits of polishing disks (a process called lapping) until the floor has the desired sheen. For an extremely highgloss finish, a final grit of 1500 or finer may be used.

How Cement Is Made

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

Future Grinding Technologies

ECRA's Future Grinding Technologies Project is based on two pillars: The first is a systematical approach towards new technologies for grinding in the cement industry. The second is the development of new and useable modelling tools for better understanding and .

How to Make Smooth Concrete Rough

Sep 27, 2012 · Most hardware stores sell concrete grinding or sanding disks that can be attached to angle grinders. These attachments can also be attached to some power drills. In order to tackle a concrete pond, you should use a large 8 inch angle grinder. This size will allow you to smooth the concrete where it needs to be smoothed, but it is small enough ...

History of cement

Cement history. Throughout history, cementing materials have played a vital role and were used widely in the ancient world. The Egyptians used calcined gypsum as a cement and the Greeks and Romans used lime made by heating limestone and added sand to make mortar, with coarser stones for concrete.

How to Polish Concrete (with Pictures)

Oct 21, 2021 · To polish concrete, start by grinding the surface with a concrete grinder, which you can rent at a hardware store. Once you've finished grinding, vacuum up the debris, and go over the entire surface with a buffer to smooth it out. Then, apply 2 thin coats of sealer to the concrete, waiting 2 to 4 hours between each coat so it can dry.

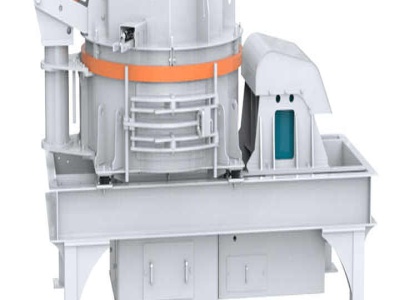

Innovation in Cement Grinding line | The Daily Star

Sep 17, 2015 · The technology is high pressure grinding mill to produce superior quality cement, in the name of Fresh brand. The grinding elements of the highpressure grinding roll .

Premier Concrete Grinding Team | Dallas Epoxy Pros

Walking in a damaged concrete is dangerous for every passerby. At Dallas Epoxy Pros, we create a safe walkway for you. Whether it?s for your garage, patio, showrooms, lobbies or entryways, we can upgrade your concrete floors to the flatness standards required via .

Metal Bond Diamond Tools,Diamond Grinding Shoes,Diamond ...

Oct 20, 2021 · Lavina Grinding Diamond Tool With 2 Bar Segments For Concrete Floor Grinding Fast Change System. Lavina diamond tooling for concrete floor with double segments are designed for concrete and terrazzo floor grinding. Lavina metal bond diamonds have two segment sizes for different appliions: 40X10X10mm and 40X10X12mm.

(DOC) Cement Manufacturing Process | SAMRAT DAS

CEMENT MANUFACTURING PROCESS PHASE II: PROPORTIONING, BLENDING GRINDINGThe raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding.

How to Easily Remove Mastic From Concrete

Aug 04, 2021 · This type of concrete grinder is great for larger projects. Their blades can grind down several feet of the floor at a time, making for a more efficient tool. Nicer models can even switch between grinding, sanding, and polishing so you can finish the whole job with just one tool. Onfloor Technology .

Decarbonising cement

Nov 02, 2021 · Jeffrey Thomas, GCP Applied Technologies (USA), highlighted how its CO 2 ST® Reducers technology is designed to reduce the CO 2 clinker factor in cement by up to 10 per cent. An industrial case study shows that, as emissions were reduced by 60kg/t of cement, this could result in a €/year saving with the ETS carbon price set at €50/t.

Effectiveness of dust control methods for crystalline ...

Concrete grinding exposes workers to unacceptable levels of crystalline silica dust, known to cause diseases such as silicosis and possibly lung cancer. This study examined the influence of major factors of exposure and effectiveness of existing dust control methods by simulating field concrete grin .

Portland Cement Manufacturing Industry: National Emission ...

Portland cement manufacturing is an energy intensive process in which cement is made by grinding and heating a mixture of raw materials such as limestone, clay, sand, and iron ore in a rotary kiln. The kiln is a large furnace that is fueled by coal, oil, gas, coke and/or various waste materials.

SELF LEVELING CONCRETE CONTRACTOR

STATEOFTHEART SELFLEVELING CONCRETE TECHNOLOGY. Self leveling concrete has increased in popularity as the degree of flatness and smoothness required for floor covering products has increased, with vinyl goods becoming thinner and floor tiles becoming larger. It is used to make the existing concrete smooth and even to ensure a perfect ...

Appliions | kladex

TECHNOLOGY TRANSFER. Mining. The limestone used in cement making is extracted from the mines and crushed to smaller size using primary crushers such as gyratory crushers, followed by jaw and rotary crushers ready for grinding. These crushers are subjected to severe impact and need to be protected by impact resistant work hardenable materials.

Latest Posts

- تعدين الفحم في المستقبل في نيوكاسل الجزائر

- مصنع البنتونيت في الجزائر

- شطبة والعتاد لكسارة

- آلة الطحن خلال الأوقات الإسبانية

- طحن ماكينات الموردين في مصر

- تكلفة مصانع فرز الحجر الجيري

- مطلوب لفتح كسارة في الجزائر

- ملف صناعة الكسارة الحجرية pdf مصر

- طحن مصنع مطحنة في الجزائر

- ريمون مطحنة بيع

- إدارة محطة كسارة مخروطية بسعر منخفض

- كسارة مخروطية puzzolana مصر

- عملية إنتاج سحق الكاولين

- صيانة محطة كهرباء ntpc dadri

- أسعار ماكينات تعدين الذهب في الجزائر

- Working Methodology Of Stone Crusher Samac

- Similarities And Differences Between Granite And Basalt

- Chrome Ore Grinding Machine

- Anti Cross Rockup Rolls In Mills

- Mining Process Of Magnesium

- 4772 Ball Mill Drawing

- System Line Magnetic Separating Process

- Details Of Asphalt And Quarry Plants

- Ball Mill Drum Manufacturer In Malaysia

- Cement Cement Plant Punjab

- Disadvantages Of Mining Iron In Pretoria Gauteng South Africa

- Machineries Used In Miningcrusher Industry

- Biaya Pabrik Semen Di Pakistan

- Coal Mine Safety Equipment

- Mini Pulverizer Machine Algeria