Operation Of Hammer Crusher

operation of hammer crusher | worldcrushers

· Hammer Impact crusher,Hammer Mill,Singlestage Hammer crusher .. Operation and maintenance of hammer crusher: frame and the liner should be checked priorly to tightening the availability of loose bolts and other bolts, ..

Operation of hammer crusher

Operation of hammer crusher Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Operation of hammer crusher, quarry, aggregate, and different kinds of minerals. We can provide you the complete stone crushing and beneficiation also supply standalone crushers ...

Hammer Crushers – MEKA Crushing Screening

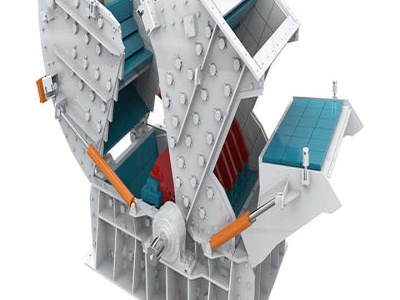

MODE OF OPERATION. The material passes through the feed opening into the striking arc of the rotating hammers. The hammers throw the material against the breaker plates, from where it rebounds back against the hammers. This process is constantly repeated and the impact of the pieces of material being crushed against each other reduces the material even more finely. The material is broken down ...

Hammer Mill Crusher Grinder

· The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll crusher and in these .

Hammer crusher HC 2x2 VIBROTECHNIK

The principle of operation of the hammer crusher is based on the impact on particles of material. The structure of HC 2x2 Hammer crusher includes: loading hopper, lid, base, rotor, electric motor and support stand. The milling chamber is formed by the inner surface of the lid, part of the base and the discharge grate installed in the base. A rotor (shaft on which two discs) is mounted inside ...

Hammer Crusher: HDS – Hazemag North America

Hammer Crusher. Double – shaft hammer crushers are mainly used in the cement industry for the comminution of soft to mediumhard, but also moist and tough materials: Limestone, gypsum, chalk, clay and marl, as well as lignite and pit coal. The crushing of the feed material is effected by percussion, impact and shear forces. Equipment. Two counter – rotating rotors crush feed material of up ...

Hammer Crusher Machine | Hammer Crusher | Cement Crusher

During the operation of hammer crusher machine, the motor drives the rotor to rotate at a high speed, and the material enters the crusher cavity evenly. The highspeed rotary hammer impacts, shears and tear the material, all the materials are broken. At the same time, the gravity of the material itself make the material from the highspeed rotating hammer head rushes toward the baffle and the ...

hammer crusher operation and maintenance

hammer crusher operation and maintenance Operation and maintenance of hammer crusher hammer crusher is a type of primary crusher which can crush material of mm to mm or even smaller size hammer crusher is widely applied to the fine and medium crushing of medium hard stone or ores in cement, chemical, metallurgy and electric power industries, such as . Maintenance of quartz stone .

HSE

The crusher should be shut off and isolated before considering the use of bars and hand hammers. Careful consideration should be given to the risk of large pieces of feed material moving and causing trap or crush injuries. Wedges should not be used due to the risk of them becoming a projectile (This has caused fatalities in the past). Other options, which require more specialist expertise and ...

Hammer crusher — Crushing machines

Hammer crusher principle of operation. The principle of operation of hammer crushers is simple, but efficient enough: a source material is continuously fed through a loading hopper, inside the machine the material is crushed under impact forces of hammers, breaker plates and grates. The crushed material falls through grate holes into the unloading device. Key features of hammer crushers ...

operation and maintenance of hammer crusher

Operation And Maintenance Manual Of High Quality Crusher. stone crusher is mainly used for crushing operation in quarry crushing plant and mining planthere are 5 types of stone crushers jaw crusher, impact crusher, hammer crusher, cone crusher, and vis crusherhat is the appliion of the 5. maintenance of crushers for cement plant.

Hammer Impact Crusher Principle Of Operation

Hammer crusher main shaft appliion in crusher main appliion in operation hammer impact crusher principle of operation recent projectthe main parts of efficient compound crusher is rollers with hammer, the rollers consists of main .

mechanical hammer crusher operation

mechanical hammer crusher operation . Hammer Mill Operating Principle. Hammer Mill Crusher. The Dixie (NonClog) Hammer Mill Crusher differs from all other hammermills in that its breaker plate, instead of being stationary, is a continuously moving belt of manganese steel links. The feed thrown into the hopper is carried by a positive mechanical feed to the hammerpoints and then on through ...

hammer crusher installation and operation

hammer crusher installation and operation_401XL Crusher Machine Manual Installation, .Machine Installation 4 3. Machine Operation 6 4. ... Remove the bolts holding the hammer shaft in the top half of the crusher. 6. Open the crusher

principle operation of hammer crusher

Describe The Hammer Crusher. before that, you can watch this video to see how hammer mills work:. hammer mill operating principle. the flanges of this drumlike assembly are,hammer crusher operation,operating principle of hammer mill: in the hammer mill machine, the motor drives the rotor rotate at a high speed through the belt, and on the rotor there

What Is Impact Crusher|Working Principle, Parts And Types ...

Advantages of impact crusher. High efficiency and large crushing chamber, high crushing efficiency and larger feed size ; Highprecision heavyduty rotor has a larger crushing ratio; Multifunctional hydraulic operating system is adopted, which is convenient for maintenance and improves equipment operation rate; High wearresistant plate hammer and liner, improve the utilization of wear parts ...

operation in hammer crusher machine project in

Operation Hammer Crusher Familienzentrum St. Joseph. operation in hammer crusher machine project operation in hammer crusher machine project Machine Operation The 401XL is a simple machine to operate It has a simple ONOFF Remove the bolts holding the hammer shaft in the top half of the crusher 6 Open the crusher again The hammer assembly and bearings should now be sitting on .

Latest Posts

- القيمة القياسية من كثافة الصخور سحق

- 2000tph مصنع غسيل الرمل النهري

- معدات التعدين في مصر والصين

- سيمونز مخروط محطم حجم تغذية 50 مم

- صغيرة المعدنية كسارة

- كسارة كاتيلابوبارا ديالجيريا 25 طن لكل هاري

- كسارة لفة sayaji المستخدمة الثانية

- مخططات تدفق عملية مطحنة البوكسيت

- ماكينة غسيل وغربلة رمل السودان

- تستخدم دلو محطم للبيع

- صغيرة النباتات كسارة متنقلة في المملكة العربية السعودية

- محطم المصنعة شمال العراق

- تكلفة الفك كسارات

- صغيرة سرعة صخرة محطم

- المملكة العربية السعودية آلة طحن أسطواني تستخدم

- Alunite Pcl Crusher Supplier

- Vme Production Wash Plant

- Review Of Butterfly Wet Grinder

- Crusher 50 Cm Feed 2

- Concrete Primary Mobile Crusher Price

- Grinder Sanding Pad Vietnam

- Diagram Aliran Tanaman Penghancur

- Impact Crusher Impact Crusher Design Impact Crusher Manufacturing

- Design Calculations Of Spring Used In Vibrating Screens

- Safety Checklist For A Jaw Crusher

- High Quality Feldspar Micro Powder Grinding Mill Plant

- Guang I Gypsum Powder Factory

- Location Puni Quarry In Temburong Brunei

- Stone Crusher Sale Philippines Stone Crusher Machine

- Crushers Crushers And Screens Manufacturers In South Africa