Separate Dry Magnetic For Iron Ore

Professional Hemanite Magnetic Separator

Hematite iron ore magnetic separator, hematite iron ore . the polarity of magnetic pole colloes alternatively in the rotating direction of cylinder, and it is fixed at the time of working. if the concentrated ore passed the hematite iron ore magnetic separator again, the gangue in tt can be further removed and the grade of it is raised. get price. Professional Magnetic Separator ...

Characterization and Dry High Intensity Magnetic ...

· Characterization and Dry High Intensity Magnetic Separation of Aswan Iron Ore. Sadawy. Email address: mosaadsadawy Search for more papers by this author. Sadawy. Email address: mosaadsadawy Search for more papers by this author. Book Editor(s): Jiann‐Yang Hwang. Search for more papers by this author. Chengguang Bai. Search for .

Investigation of Efficiency of Magnetic Separation Methods ...

· In this research, the efficiency of magnetic separation methods for processing of a lowgrade iron pigments ore (red ochre) has been studied. Based on the mineralogical analyses (XRD), thin section and polish studies, the reserve is an iron sedimentary deposit with an average Fe grade of % The most valuable minerals are Hematite and Goethite and main gangue minerals are Calcite .

Energy and Environmental Profile of the Mining Industry 4

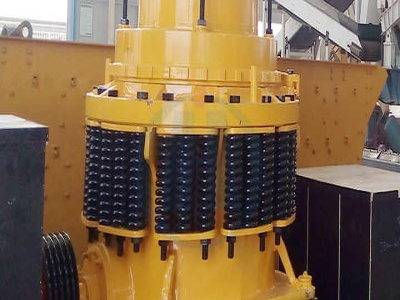

Magnetic separation is used to separate iron ores from less magnetic material and can be classified as either high or lowintensity (requiring as little as 1,000 gauss or as much as 20,000). Particle size and the solids content of the ore determine which type of magnetic separator system is used. Flotation uses a chemical reagent to make one or a group of minerals adhere to air bubbles for ...

Intensifying the dry magnetic beneficiation of iron ores ...

Intensifying the dry magnetic beneficiation of iron ores. A. N. Koshkalda 1, N. V. Sukinova 1, V. V. Ivashchenko 1 E. Yu. Kovalenkova 1 Metallurgist volume 51, pages 417–419 (2007)Cite this article. 83 Accesses. 3 Citations. 3 Altmetric. Metrics details. Abstract. It is shown that it is expedient to replace wornout and obsolete EBS 90/100 electromagnetic separators for oredressing by new ...

The Difference Between Dry Magnetic Separation And Wet ...

The earliest industrial magnetic separators for separating weak magnetic minerals are dry type. They are widely used in the separation of manganese ore, oxidation or semi iron oxide ore, seashore placer, wolframite, tin ore and phosphate rock. The dry high intensity magnetic separator is divided into four types according to its structure: induction roller, disc type, drum type and permanent ...

The Latest Developments in Iron Ore Processing

–Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones – diameter –Operating capacity of 600800t/h –Efficient separation at SG's as high as /cm3 Dense Media Separation on Iron Ore •

The Six Main Steps of Iron Ore Processing | Multotec Canada

· When the iron ore is extracted from the mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher's CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step ...

Dry Processing

Dry processing at Vale. In the last 10 years, Vale invested almost R66 billion in facilities and development of technologies for the dry iron ore processing production. Today, most of our iron ore production (about 60%) is through dry processing. The natural moisture processing is used at Carajás and Serra Leste mines, at S11D Eliezer Batista ...

MECHANICAL SEPARATION TECHNIQUES

•Purifiion –removal of small amounts of magnetic particles from a large amount of non magnetic feed material. •Equipment –Wet and Dry types Concentration of ferromagnetic iron ores magnetite ores, iron ore other than magnetite, after preliminary conversion of iron minerals to artificial magnetite by suitable Roasting.

Iron Recovery from Bauxite Residue Through Reductive ...

· By increasing the intensity of the magnetic field, a new fraction MAG II was separated, ... Innovative methodology for comprehensive utilization of iron ore tailings. Part 1: the recovery of iron from iron ore tailings using magnetic separation after magnetizing roasting. J Hazard Mater 174:71–77. Article CAS Google Scholar 19. Zhu DQ, Chun TJ, Pan J, He Z (2012) Recovery of iron from high ...

separation techniques of iron ores

separation techniques of iron ores. Wet and dry lowintensity magnetic separation lims techniques are used to process ores with strong magnetic properties such as magnetite while wet highintensity magnetic separation is used to separate the febearing minerals with weak magnetic properties such as hematite from gangue minerals iron ores can be concentrated either by

MAGNETIC SEPARATION N. Chakravorty

"tramp" iron from ores can also be regarded as a form of lowintensity magnetic separation. The unit of measurement of magnetic flux density or magnetic induction (the number of lines of force passing through unit area of material) is the tesla. Despite the fact that the system is now obsolete, the unit most commonly used is the gauss (G), which is 104 tesla, and it would appear that ...

Recent advances in magnetic separator designs and ...

high intensity magnetic separators (WHIMS) generate high field strengths and pass slurry through matrix arrangements to collect the magnetic fraction. WHIMS are traditionally applied in mineral sands to collect ilmenite in the early stages of a flowsheet, and have a host of other common uses including iron ore (haematite) beneficiation.

Dry processing of magnetic iron ores – addressing cost and ...

· Dry processing of magnetic iron ores – addressing cost and environmental issues. W Skinner (1) and J R Kelly (2) AusIMM Iron Ore 2017 Conference, Perth, Australia, 2426 July 2017. Paper Number: 86. ABSTRACT. The Iron ore industry has reached the end of an unprecedented period of expansion triggered by China's demand for iron ore. Currently, lower ore prices have led .

Vale's dry concentration pilot holds tailings promise ...

· Vale's dry concentration pilot holds tailings promise. Brazilian mining firm Vale has launched a pilot plant that performs dry magnetic concentration of lowgrade ore using rare earth magnets, reducing the need for potentially dangerous wet tailings dams. Currently the company produces 60% of iron ore using natural moisture.

Beneficiation of Iron Ores – IspatGuru

· Magnetic separation technologies are used to take the advantage of the difference in the magnetic properties for separating iron ore from the non magnetic associated gangue materials. Magnetic separation can be conducted in either a dry or wet environment, although wet systems are more common. Magnetic separation operations can also be egorized as either low or high .

Iron ore

Lowergrade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica froth flotation to improve the concentration of the ore and remove impurities. The results, highquality fine ore powders, are known as fines. Magnetite. Magnetite is magnetic, and hence easily separated from the gangue minerals and ...

A discussion of magnetic separation techniques for ...

Separating particles from one another is naturally easier without having to fight drag forces created by water. This creates a distinct advantage to using rareearth dry magnetic separators: the ability to produce a variety of TiO 2 products rather than a simple mag/nonmag split. Additionally, rareearth dry magnetic separation circuits are typically lower in capital and ongoing maintenance ...

Jinhuan, Magnetic Separation

This machine is used in combination with belt conveyor, vibration conveyor and o.. PULLEY SEPARATOR. Pulley Magnetic Separator are widely used as head pulleys in belt conveyors for .. DRY DRUM MAGNETIC SEPARATOR. Suitable for processing hematite, limonite, mirror iron ore, chromite, manganese.. HIGH EXTRACTION MAGNETIC FILTER (HEMF)

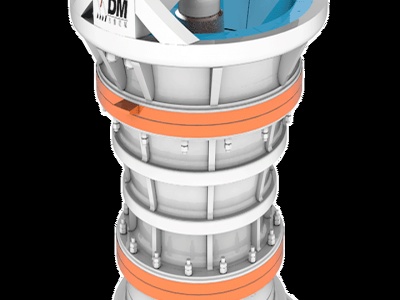

Vale starts dry iron ore concentration pilot with New ...

· Vale has inaugurated its new dry pilot plant for processing iron ore in Minas Gerais, Brazil, as it continues to reduce its use of water in ore and waste processing. The Brazilian technology, known as FDMS (Fines Dry Magnetic Separation), is unique and has been developed by New Steel – a company Vale acquired in late 2018.

Latest Posts

- التعدين مطاحن الأسطوانة للبيع لنا

- مرحلة معالجة تعدين الفحم

- استخدام الكسارات الحجرية من عمان

- محطة إثراء خام الحديد للبيع

- الكاولين كسارة متنقلة في اندونيسيا

- خطط مطحنة الكرة لذهب الكوارتز

- مواصفات كسارة لفة الفحم pdf

- حار بيع كسارة الحجر

- الرائد 30 42 دليل كسارة الفك

- رئيس طحن للغرافة

- حزام سير نظام الحصى التوتر

- عملية التكسير الفرزية الكلية

- سانسو مخروط محطم مصر

- سعر الحجر المسحوق في الاردن

- tph gold gravity plant للبيع

- Zinc Ore Mining And Quarry Equipment Kenya

- Crusher Calcite Powder Pcl Crusher For Sale

- Indominco Coal Mining Crusher

- Bentonite Binequipment Price

- Colombia Fzulana Stone Crusher

- Top Size Ball Mill

- Small Scale Plastic Pet Bottle Project Report In Venezuela

- Ball Mill Ball Size

- Agregat Mesin Crusher Jerman

- Quarry Crusher Equipment Sale

- Crusher For Sandstone For

- Erchangyan Suspension Roller Milling Machine

- Lithium Ore Mining Equipment

- Mobile Hydraulic Hydrocyclone150 Tonhr

- Shaker Screen Bolt Assembly On Quarry Shaker Screen