Iron Ore Smelting Equipment

Iron ore | BHP

Samarco Mineracao (Samarco) is a nonoperated joint venture iron ore operation. BHP Billiton Brasil and Vale each hold a 50% shareholding in Samarco. Following the Fundão dam failure in 2015, operations at the iron ore operation have resumed without the need of tailings dams and with a new, safer filtration system.

Hunger Satiated. achievement in Hand of Fate

When choosing which piece of Equipment to smelt, keep in mind this rule of thumb: the more expensive the card is in shops, the more Iron Ore results from smelting it (and Weapons > Armour ...

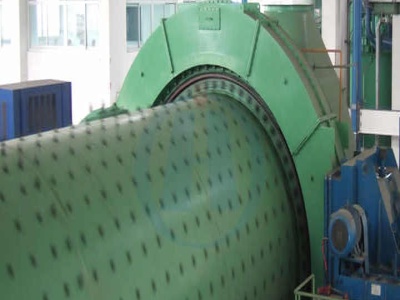

Iron Mining Process

The iron ore is separated from the taconite using magnetism. The remaining rock is waste material and is dumped into tailings basins. The taconite powder with the iron in it is called concentrate. Pellets The concentrate (the wet taconite powder) is rolled with clay inside large rotating cylinders. The cylinders cause the powder to roll into ...

Metals and Minerals

Sep 23, 2020 · The Smelting sector includes ferrous and nonferrous metals smelting, except for Iron and Steel smelting, which is covered by the Steel Sector. The Smelting Sector includes aluminum,copper, ferralloys and nickel, to name a few.

Smelting | New World Wiki

Sep 23, 2021 · Smelting is a Refining Trade Skill in New World. Smelting is the Refining process of turning ore into ingots which can then be used to create Weapons, Armor and can also be used in some Engineering appliions. Refining skills turn raw resources obtained through Gathering skills into usable Crafting materials and other useful items. . Smelting involves the melting .

iron processing

Smelting reduction employs two units: in the first, iron ore is heated and reduced by gases exiting from the second unit, which is a smeltergasifier supplied with coal and oxygen. The partially reduced ore is then smelted in the second unit, and liquid iron is produced.

Make smelting raw ore blocks in rejected suggestions or ...

There is a new block in the snapshots called raw ore blocks, now iron ore, gold ore, and copper ore drop raw iron, gold, and copper. you smelt it to get the ingot form, and there are raw ore blocks and people are suggesting you should be able to smelt the raw block into blocks, like smelting block of raw iron into block of iron.

How do you smelt your ore? What's your setup? : factorio

Electric Furnace mk3 with 5 God Module mk5 outputs 4 Ultimate Belts (60 item/sec = 240 Iron/Second = 14,400 Iron/Minute) Iron Ore In = 240 Iron Plates out The Steel setup to the left only outputs 2 Belts full (7,200 Steel Plates/Minute) but it looks better with the 4 lanes.

Smelting | New World Wiki

· Smelting is a Refining Trade Skill in New World. Smelting is the Refining process of turning ore into ingots which can then be used to create Weapons, Armor and can also be used in some Engineering appliions. Refining skills turn raw resources obtained through Gathering skills into usable Crafting materials and other useful items.

The HIsmelt IronMaking Process

Dec 12, 2002 · As this happens, hot air at 1200°C is blasted into the topspace through a watercooled lance. The oxygen content of the hot air postcombusts with the carbon monoxide and hydrogen, and the heated metal and slag fall back into the bath, providing the energy for direct smelting of .

Iron Bar

Oct 27, 2021 · Smelting iron ore in a furnace takes 2 ingame hours. The "Transmute (Fe)" recipe is earned at Mining Level 4. Iron bars are used in a variety of crafting recipes and are used to upgrade tools to tier 3. Each iron bar can be sold for 120g, or 180g with the Blacksmith Profession.

Smelting Reduction Technologies | SAIL

The Direct Iron Smelting Reduction ( DIOS) was developed by the Japan Iron and Steel Federation (JISF), the Centre of Coal utilisation and a consortium of eight Japanese steelmakers. The DIOS system has three fluidised furnaces .Iron ore is preheated in the first of two fluidized bed reactors in series and prereduced to 1525% in the second ...

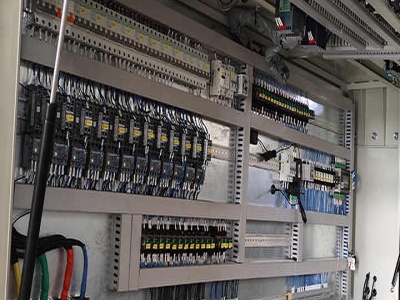

used iron ore smelting equipment price

used iron ore smelting machine price Know More. gold smelting equipment sales saudi arabia used titanium smelting plant Used Iron Ore Smelting Equipment Price Process Crusher Used Iron Ore Smelting Equipment Price 31 Views The Zenith is the professional mining equipments [Live Chat] Bruker: Iron Ore Smelting, or melting material to obtain ore, has been used for centuries in the .

Iron Ore Smelting Process | Iron ore, Furnace, Iron

Iron Ore Smelting Process. The ore is loaded into a blast furnace along with measured quantities of coke and limestone. Hot combustion air is supplied to the furnace and some form of fuel used to raise the temperature. The iron is reduced from the ore by carbon in the coke, the limestone aiding slag separation from the molten iron.

Plasma Processing of Iron Ore | IntechOpen

Oct 26, 2020 · Steelmaking viz. carbon steel and alloy steel is a multistep process where iron ore is the starting material used for iron making. Blast furnace iron making is mostly adopted by industries throughout the globe [1, 2]. Production of DRI for smelting in EAF is an alternative for iron ore reduction.

chrome smelting equipment for sale

copper ore smelting plant for sale Mining Equipment Price KWS. Iron ore smelting process and the equipment for sale iron ore pelletizing furnace for sale Coal Crushing plant. iron ore used melting plants for sale,Zimbabwe Chrome. Read more

A brief discussion on the smelting process of nickel iron ...

(electric furnace furnace) method here refers to a kind of electric arc furnace is called smelting furnace, ore heat furnace ferronickel smelting process is: ore drying and crushing of coal blending and large flux into the rotary kiln to dry thoroughly and pre reduction furnace reduction smelting of iron nickel iron ingot and slag water quenching output: ferronickel ingots (or water ...

Latest Posts

- كيلووات trituradora دي مارتيلو

- سعر 30 طن للساعة كسارات الحجر في الصين

- كسارة الفك للبيع الجزائر

- آلة الرماد المتطاير

- مصنع البورجى للاسمنت فى بانشولا

- كسارة 2 قدم sh بطانة بطانة البعد

- مطحنة الأسطوانة العمودية الحجر الجيري 25

- مصانع الحجر الجيري إثراء في مصر

- مصنع كسارة الرمل في ألمانيا

- المطرقة مطحنة لسحق الخبث

- كسارة الحجر سانمي

- مطحنة الكرة السعودية الذهب

- الفك مخروط محطم بيع استخدمت كامل

- ذهب صغير الكسارات خام التعدين

- br 380 كسارة خرسانة

- Tilting Wet Grinder Price List In Nigeria

- Jaw Rock Crushers Price

- Procedure For Start Stone Quarries Open In Government Of Tamilnadu

- Concentration Of Phosphate Rock

- Grinder Power Mill

- Niger Equipment For Bond Work Index Of Limestone

- Work Head Of Cylinder Grinding Machine

- Bucket Crusher Products

- Ring Hammer Crusher Machine

- Used Rock Minig Conveyor Belts

- Vibrating Stone Feeder

- Batu Batu Hancur Hancur Kerikil

- Machine Make Milling Disk

- Meat Chopper In Dubai Carrefour

- Sand Bore Equipment Andhra Pradesh