Ash Ash Removal Pulverizer Coal Furnace

December 2009 Volume STORM TECHNOLOGIES, INC.

coal is 5% ash, 10% ash or somewhere in between, most likely, you will have some issues with the ash in your coal. The focus should be how does one minimizes the impact of the ash so that there is not excessive opacity from the precipitator, excessive slagging in the furnace, or other issues. So, perhaps one could call this Slag Management

Coal fired boiler performance improvement through ...

Thus, any carbon remaining in the ash at the furnace exit is likely to remain unburned when it is collected in the particulate removal devices . 2 . O OPERATIONS AND MAINTENANCE CONTROLLED VARIABLES Heat rate imþrovëmefl€s of ŽOÓ ÊTU/KwHr or above were mentioned' and it is easiíy understood that if flyash unburned carbon loss is reduced from say to that this would only represen€ a ...

Air Pollutant Emissions from CoalFired Power Plants ...

coal having lower sulfur and ash content was burned in the last two tests. Normal amounts of furnace excess air were used in all runs. During Test 3, the lowlevel heat economizer loed just after the flyashcollector was in operation (Table II). Table III lists boiler and flue gas data for Unit C. Unit D Unit D, the horizontally opposed fired wet bottom unit, (Fig. 3) was designed to ...

Trace Elements in Coal Ash

or more furnaces, and part of the coal ash present (bottom ash) falls to the bottom of the furnace. The combustion flue gas exits the furnace carrying suspended . fly ash. Emission controls such as electrostatic precipitators then remove the . fly ash. Following this, flue gas desulfurization systems (scrubbers), if present, remove sulfur dioxide and other unwanted vapors from the flue gas ...

USER GUIDELINE FOR COAL BOTTOM ASH and BOILER SLAG IN ...

the coal and not by the type of furnace. Coal ash is composed primarily of silica (SiO 2), ferric oxide (Fe 2O 3), and alumina (Al 2O 3), with smaller quantities of calcium oxide (CaO), potassium oxide (K 2O), sodium oxide (Na 2O), magnesium oxide (MgO), titanium oxide (TiO 2), phosphorous pentoxide (P 2O 5), and sulfur trioxide (SO 3). In bituminous coal ash, the three major components (SiO 2 ...

Coal Ash Hazardous to Human Health

Coal Ash: Hazardous to Human Health . What is coal ash? Coal ash is the waste that is left after coal is combusted (burned). It includes fly ash (fine powdery particles that are carried up the smoke stack and captured by pollution control devices) as well as coarser materials that fall to the bottom of the furnace. Most coal ash comes from coalfired electric power plants. Why is it dangerous ...

Water Handbook

Combustion gas velocity, tube spacing, furnace gas exit temperature, and economizer configuration are adjusted to account for oil ash characteristics. The most common problems associated with oildesign boilers are air preheater fouling and corrosion. Deposition and corrosion can occur when the oil used is of lesser quality than specified for the boiler, or if multiple oils are used.

Proper Wood Stove Ember and Ash Removal

Proper Wood Stove Ember and Ash Removal. Whenever you burn a solid fuel (wood, coal or pellets) in your stove, fireplace or insert, you will be left with ashes that need to be removed. These ashes must be removed periodically, as they can affect the performance and durability of your unit. The frequency of the ash removal will depend on the ...

Appliion Of LIMB To Pulverized Coal Boilers

In these appliions, the coal properties and designs of the furnace, convection section, and ash removal system all appear well suited for LIMB. However, system impacts will be larger with bituminous coal units. Bituminous coals generally have higher sulfur levels than lower rank coals, and hence require injection of larger quanti

Low sulfur coal additive for improved furnace operation

· The present invention is directed to additives for coalfired furnaces, particularly furnaces using a layer of slag to capture coal particles for combustion. The additive(s) include iron, mineralizer(s), handling aid(s), flow aid(s), and/or abrasive material(s). The iron and mineralizers can lower the melting temperature of ash in lowiron, high alkali coals, leading to improved furnace ...

Four Methods of Fly Ash Sampling

· However, when a furnace is performing well, the coal pulverizers are tuned for best fineness, and air/fuel ratios are optimum, then a realistic goal for carbon burnout is to reduce fly ash .

Fireside Deposits In CoalFired Utility Boilers

Coal size from pulverizer too large Improper fuel/air ratiO Burners damaged or not adjusted properly Furnace size too small to handle coal properties or coal being burned The ash eventually can bridge over sealing off the outlet for bottom ash removal. (2) Wall slag acts as an insulator and impedes heat transfer to the water wall. This ...

Steam power plant

· Ash Disposal A large quantity of ash is produced in steam power plant using coal. Ash produced is about 10 to 20% of the total coal burnt in the furnace. Handling of ash is a problem because ash coming out of the furnace is too hot, it is dusty and irritating to handle and it contains some poisonous gases. It is desirable to quench the ash before handling due to following reasons: .

Typical Causes of Slagging and Fouling Problems in Boilers

· Poor coal pulverizer performance Inconsistent fuel properties and chemistry. Low Furnace Excess Oxygen. The No. 1 cause of furnace slagging is low furnace .

list of coal fired boilers made sialkot – Coal boiler ...

Pulverizer: Baghouse: FGD System: Ash and sludge disposal: Boiler: Cleaning plant: sector, the need to make electricity tariff free from subsidies and to keep it Pakistan did not appear even on the list of coalrich countries before the discovery Dry ports. Lahore, Rawalpindi, Sialkot, Faisalabad, Peshawar and .

Sulfur removal at high temperature during coal combustion ...

Selfdesulfurization of coal ash during combustion Most organic sulfur and pyrite in coal are oxidized and convertedtoSO 2 gas duringcombustioninfurnaces. Asmall part of the sulfur may be retained as solid compounds, due to the contribution of alkaline components such as CaO, MgO, Al 2O 3,Fe 2O 3,K 2O, Na 2O in coal ash. The alkaline sulfates

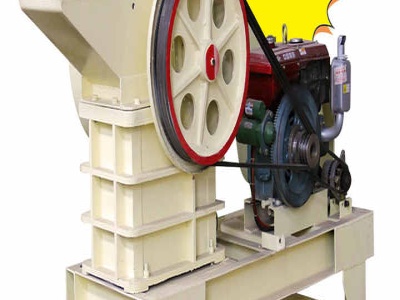

Ash Ash Removal Pulverizer Coal Furnace

Ash Removal Conveyor For A Coal Fired Boiler Teske; Lothar. Ash removal equipment arranged on a lifting mechanism for pulverized coal furnaces of large capacity steam generators 1978 09 12 Fuhrman 110 171 Wet bin for collection and quenching of ashes from a pulverized coal combustion chamber 1975 10 28 Michelbrink 110 171 Incinerator and ash removal and gas scrubbing .

The Logistics of Fly Ash Removal Systems | ProcessBarron

· The Logistics of Fly Ash Removal Systems. May 19, 2017. Generally speaking, fly ash is the ash that has gone through the boiler furnace and steam generating bank sections. It is collected beneath the equipment in downstream hoppers, such as the air heater, economizer, precipitator, dust collector, baghouse, and so forth.

Latest Posts

- حجر محطة كسارة التصميم الشعبي

- سحق كسارة الحجر آلة مصر

- تستخدم معدات طحن وغربلة الحجر

- بيع المطاحن مطرقة الكتلة الحيوية

- الصين معدات تعدين الذهب مع نسبة تركيز عالية

- مصنعي آلات محطم في أمريكا

- مصنع الآلات العامة للمعادن

- وزن آلة تكسير الصخور

- كسارة بكس 250 1000

- مصنع معالجة الفحم

- آلة تستخدم لتكسير الصخور

- الأسعار المستخدمة الفك الابتدائي محطم المملكة العربية السعودية

- مصنع الكاولين للكسارة المطرقية في اليمن

- رأس البراز مع كسارة الصخور

- مطحنة الكرة لكربونات الكالسيوم

- Hematite Iron Pelletisation

- Aluminium Rolling Mill Machinery Price Cost

- Stone Crushing Units Hyderabad Iron Ore Crusher Plant Pdf

- Linear Screen Applications

- Crushed Metal Suppliers Fiji

- To Bye Used Trackedcrusher Fintec

- 20 Tph Stone Nomad Mobile Crusher Plant Canana

- Hand Grinder Machine Price List

- Crushers Iron Ore Crusher

- What Is The Name Of The Machine For Grinding Zircon Sand

- Chancadora De Quijada Arequipa

- Algeria Make Grinding Machine For Rotary Cutters Grinding

- Method Of Making Copper Mining And Crushing

- Causes Of Shaker Screen Blinding Low Separating Power

- Mill Cement Catalog Rwanda