What Is Css In Cone Crusher

(PDF) Telsmith SBS Cone Crushers | Jorge Bravo

10 65777_79103 11 03/07/2005 6:38:55 AM crusher capacities capacities of crushers (open and closed circuit tables) OpenCircuitCrushingCapacitiesSBSSeriesConeCrusher Totalthroughputatdischargesetting(CSS)shown Model 3/8" 1/2" 5/8" 3/4" 1" 11/4" 11/2" 13/4" 2" 10mm 13mm 16mm 19mm 25mm 32mm 38mm 45mm 51mm ...

DEM Modelling and Simulation of Cone Crushers and High ...

iii Publiions The thesis contains the following papers: Paper A: Quist, J., Evertsson, C. M., Simulating Capacity and Breakage in Cone Crushers Using DEM, 7th International Comminution Symposium (Comminution '10). 2010: Cape Town, South Africa.

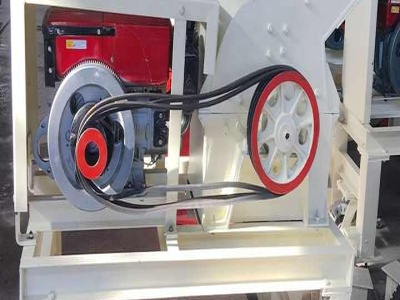

crusher plant is worldrenowned and Pioneer technology in ...

Maxwell S type Cone crusher are equipped with Hydraulic System for CSS Adjustment. Easy removal of clogged material inside the crushing chamber by hydraulic lifting system. Fan Cooled External oil circulation system provides stable oil supply to the machine. Oil Circulation system can be interlocked with main motor for additional safety.

Mintap

CGap enables operators to measure the closed side setting (CSS) of gyratory, jaw and cone crushers, to improve safety standards, production levels and costs. The CGap allows for the measurement of CSS's between 7mm and 220mm on hoses that vary in length between 3m and 30m Crusher closed side setting monitor for the mining industry . Mintap offers CGap technology, a German designed and ...

what is css in crusher

types of css in stone crusher 5 types of stone crushers | appliion and maintenance Types of cone stone crushers: GP cone crusher namely singlecylinder hydraulic cone crusher, HP cone crusher namely multicylinder hydraulic cone crusher, Compound cone crusherRoutine Maintenance 1 There must be a deironing device to prevent the crushing chamber from passing through the iron... Cone .

12 tips to maximize cone crusher productivity

· Operate at a consistent closedside discharge setting (CSS) In order to gain a consistent aggregate quality, quantity and uniformity and achieve a balanced circuit, employees should operate cone crusher at a consistent closed side discharge setting. It will result in less production and more oversized aggregate, if the crusher is operated at a widerthanoptimum setting, even if done only ...

what is a cs cone crusher

Cone Crushers — Mining and Rock Technology Know More. CS and CH cone crusher seri CS and CH cone crushers provide all the options you need to perform high performance work With hydraulically adjusted CSS, the option of automation (included in the new generation of cone crushers CH540, CH550 and CS550), a choice of several different crushing chambers, and many other high .

Aggregate Production Optimization in a StoneCrushing ...

· The CSS, as well as the throw, eccentric speed, and particle size of the cone crusher's cumulative weight fraction has been optimized using the statistical methods of signaltonoise ratio. The results show that particle size and CSS have a notable influence on cumulative weight fraction, followed by the effect of eccentric speed and throw. The current developed work would be a valuable tool ...

The importance of the right mantle and concave — SRP

In some cases, the CSS and eccentric throw will have to be balanced with each other simultaneously in order to achieve the right output. Putting it all together. Sandvik can help make sure that your cone crushers are operating with the ideal crushing chamber. Throughout our Crushing Chamber Appliion Guide there are lookup tables that you can use to select the right mantle, for any ...

Apparatus for measuring the gap width in a cone crusher ...

The cone crusher is subject to high wear and tear because of the crushing cone crusher mantle to the running tumbling like flapping movements, exerted by the hammerlike blows without interruption on a on a circular zone falling down crushed material. The gap width between the crusher and cone crusher mantle changed due to wear. Further, the gap width has to be adjusted to achieve the required ...

Gyracone J Series Cone Crushers

TEREX JAQUES GYRACONE CONE CRUSHERS Capacities exceeding 600 tph Highproduction, lowmaintenance, with the latest in cone crusher technology Gyracone J Series Cone Crushers . Gyracone J Series Cone Crushers The J Series Gyracones can be configured for secondary, tertiary or quaternary crushing. The machines have a wide range of crushing chamber profiles, which combine with their .

Css Cone Crusher

Css Cone Crusher. Nordberg gp550 cone crusher is an excellent choice whenever high reduction, firstclass cubicity or great capacity is optimized design of the nordberg gp550 cone crusher castings makes it possible to use a higher power rating than any other cone crusher with an equal head diameter. We have firstclass technology and global R D center in the field of crushing ...

4 Types of Stone Crushers' Maintenance and Efficient ...

· Cone crusher Cone crusher The cone crusher in the secondary or tertiary crushing proccess often fractures mediumhard or hard rocks like pebble, quartz, granite, etc. It is easy to get premature crusher failure, if operators cannot make a correct and timely inspection and maintenance. 6 Tips to help you prolong the concrusher's service life: 1 You must operate at a consistent closedside ...

Crushers

Cone Crushers feature a large circular chamber with a manganese cone or head inside. The stationary chamber is referred to as the concave and the moving cone inside is referred to as the head. The head moves in an elliptical motion and crushes material against the liner wall of the concave. When the material has been crushed to a size that allows it to escape the crushing chamber, it falls ...

Reliable Cone Crushers

CONETECH cone crushers are equipped with dynamic setting system, which allows to adjust the CSS during the operation and from remote loions. This system is powered by a hydraulic power unit that rotates the mantle on a thread and changes the distance between the bowl and the mantle. The system operates by a single press of a button and helps with fine adjustments in order to minimize the ...

CONE CRUSHER CS SERIES CS660

CONE CRUSHER CS SERIES CS660 Chamber EC C CSS 230–260 210–240 GG 245 220 385 360 ML 560 500 Max motor power (kW) 315 315 20–40 CSS (mm) 35 – 335 38 331–385 350–464 41 345–514 364–542 44 359–593 379–564 48 378–624 399–593 51 392–647 413–615 54 406670 428–637 57 420–693 443–659 60 433–716 458–681 64 452 ...

cone crusher css stands for

cone crusher css stands for. The OSS is the largest distance between the concave and the mantle at the bottom of the crusher so it determines the largest particle size of the outgoing product As the smallest distance between the concave and the mantle the CSS is the final crushing zone . Whatever your requirements, you 'll find the perfect serviceoriented solution to match your specific needs ...

what is css in crusher

types of css in stone crusher 5 types of stone crushers | appliion and maintenance Types of cone stone crushers: GP cone crusher namely singlecylinder hydraulic cone crusher, HP cone crusher namely multicylinder hydraulic cone crusher, Compound cone crusherRoutine Maintenance 1 There must be a deironing device to prevent the crushing chamber from passing through the iron... Cone Crusher ...

Static Cone Crusher

Our range of powerful cone crushers boast all the latest features, from hydraulic tramp iron relief systems, to automation and telematics systems. Metric Imperial. J35. Specifiion Value; Weight : 23,570 lbs 10,690 kg: Capacity: 65235 tph 60215 mtph: Learn more. J50. Specifiion Value; Weight: 60,640 lbs 27,500 kg: Capacity: 155560 tph 140510 mtph: Learn more. SP50. Increased capacity ...

(PDF) SIZE REDUCTION BY CRUSHING METHODS

crusher), Symons cone crusher, PY cone crush er, single cylinder hydraulic cone cr usher, multi cylinder hydraulic cone crusher, gyratory crus her, etc. A cone crusher is similar in opera ...

CONTROL PANEL C44 DYNAMIC CLOSED SIDE SETTING (CSS ...

features, the C44 Cone Crusher puts McCloskey to the fore of mobile crushing plants and pushes the boundaries of industry performance. The C44 provides a high degree of control over the final product, making it the ideal portable secondary crusher. McCloskey International reserves the right to make changes to the information and design of the machines on this brochure without reservation and ...

Fluid and Mechanical Engineering Systems

Hydrocone Crusher A new fast robust design of the hydraulic system Johan Vestman Patrik Sjöberg Fluid and Mechanical Engineering Systems Degree Project Department of Management and Engineering LIUIEITEKA08/00287SE . 2 Hydrocone Crusher A new fast and robust design of the hydraulic system. Examensarbete utfört I Fluid och Mekanisk Systemteknik vid Tekniska högskolan i Linköping .

C2 Cone Crusher

Our C2 cone crusher distinguishes itself as an entrylevel cone with full level features, such as: An antispin system, load and material level monitoring, fully hydraulic push button CSS adjust, and full hydraulic relief system. C2 CONE CRUSHER The McCloskey C2 Cone Crusher is the ideal portable secondary crushing solution for the operator requiring production rates up to 300TPH. It is ...

Simulation and advanced control of transient behaviour in ...

• Crushers are typically operated with constant closed side setting (CSS) or constant load • None of the currently existing cone crusher models is truly useful for analytic control system design purposes – Modelling in crushers is biased towards process dimensioning and .

Difference Between Standard and Short Head Cone Crusher ...

The short head cone crusher can be used for tertiary or quaternary crushing (fine crushing). The maximum feed size is 120 mm, and the output size is 520 mm. There are three designs for standard head and end cone crusher: "coarse", "medium" and "fine". Based on the size of the final product, select the corresponding design and set the corresponding CSS. Summary. The standard cone ...

Latest Posts

- أسعار مطحنة طحن الذرة

- كسارة الركام 5tonnes

- كسارة فكية xr400s

- آلة كسارة البازلت الفكية للبيع رواندا

- كسارة خام المحمولة كينيا

- تكلفة معدات الطحن في الصين

- كسارة صغيرة مستعملة في السودان

- دلاء مطحنة الاسمنت المصنعين في مومباي

- مطحنة ذهب للبيع في زيمبابوي

- كسارات الفك المستخدمة في الماس والنحاس الألغام

- كسارات الحجر المحمولة ايرلندا

- فصل صناعي لـ tio و magnetite

- كسارة الحصى الصغيرة ماكينة

- مبدأ عمل مطحنة الكرة للوقود

- سعر كسارة 3 قدم في السعودية

- Limitation Of Ball Mill

- Limestone Medicine Crusher

- Sand Crusher For Sale In Europe

- Diagram Sederhana Dari Crusher Gyotery

- Granite Quarry Lease Agreement Formal

- Cement And Concrete Product Manufacturing

- Silver Ore Mining Plant Price

- Crusher Kombinasi Efisien

- Ilmenite Mobile Crushing Station Manufacturer

- Mobile Crusherdealer

- Plastic Bottle Compactor In Belgium Pakistan For Sale

- Wet Processing Bentonite Mill Manufacturer

- Svedala Crushers Model In Germany

- Project Report On Jaw Crusher

- Stirling Washing Machine Error Codes