Crusher Production Of Clinker

DEB3

The invention relates to a method for cooling and comminuting hot cement clinker (1) in a cooler (3) and a corresponding device, wherein the cooler (3) has an inlet area (5), a recuperation area (7), an end cooling area (17), at least one opening (10) for blowing cooling air (11) into the recuperation zone (7), a tertiary air line (13) for discharging heated cooling air (11), a discharge area ...

Inservice Performance of HighManganese Steel Clinker ...

· Highmanganese (Mn) cast steels (HMS) exhibit high toughness, wear resistance, high workhardenability and have a relatively low cost of production, which makes them suitable for rock crushing and sizing operations. Although highMn steels have limited high temperature applicability, they have been used in clinker crusher operations as well. In this study, the inservice performance of .

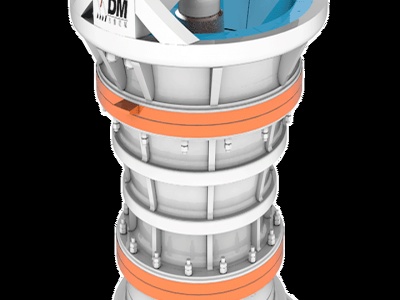

PYROFLOOR²

for production capacities from 2500 tpd to 10000 tpd. Wear resistant impact plate lining on the inner walls of the housing, hard faced hammers, option of air cooled roller shaft, specially angled grisly bars and a heavy duty chain curtain make KHD hammer crusher one the most reliable and robust clinker crushers available. 23 HAMMER CRUSHER

Clinker Production

It starts with crushers that feed raw material storage. The raw materials are fed to raw mills that feed the raw material silos. Finally, the raw materials are conveyed to kilns where they are transformed into clinkers. The clinkers are processed in cement mills and then stored in the cement silo. Currently Akçansa derives its production plan conventionally and does not take into account ...

on making 1 ton of cement, how many clinker (in ton) needed

Clinker Production by Process, 1970 to 1999 (expressed in .... While many different fuels can be used in the kiln, coal has been the ..... departments of the company to bring together the wide expertise needed for... Read more. Naik and Moriconi University of Wisconsin–Milwaukee. reducing the needs for clinker making and calcinations. ... One ton of portland cement clinker production ...

crushing and pre homogenizing of clinker

From the clinker silo, clinker is transferred to the clinker bin. Production Process Anhui Conch Cement Company Limited Pendulum crusher can crush the block limestone utmost 1500mm to below 70mm at one time. ...

Manufacturing Process – Continental Cement

The clinker is ground in a ball mill—a horizontal steel tube filled with steel balls. As the tube rotates, the steel balls tumble and crush the clinker into a superfine powder. It can now be considered Portland cement. The cement is so fine it will easily pass through a sieve that is fine enough to hold water. A small amount of gypsum is added during final grinding to control the set.

Us Manufacturers Of Cement Clinker Crush

Crush Ciment Clinker FM Fachmonteure GmbH Cement mill is the key equipment for grinding after the crush process which is widely used in the manufacture industries such as cement silie new building material refractory material fertilizer ferrous metal nonferrous metal and glass Contacter le fournisseur » crushing More Detail . us manufacturers of vertical cement crushers. us manufacturers ...

equipment for crush clinker

equipment for crush clinker. In the cement production line we use cement crusher for cement crushing process then we need cement mill for fine grinding stage As a kind of cement grinding machine Cement mill is the equipment used for grinding the hard nodular clinker from the cement kiln into the fine grey powder that is cement. Online Chat equipment for crush clinker. clinker crushing station ...

Cement clinker

Cement clinker is a solid material produced in the manufacture of Portland cement as an intermediary product. Clinker occurs as lumps or nodules, usually 3 millimetres ( in) to 25 millimetres ( in) in diameter. It is produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilie materials such as clay during the cement kiln stage.

Cement Plant | Clinker Equipment Manufacturer | SINOMALY

Characteristics of Cement Clinker Production Line: Limestone Crushing Equipped with 2 jaw crushers. The subraw materials like clay and sandstone are crushed by one roll crusher and one impact crusher. The iron powder is conveyed to the subraw material homogenization silo directly by the hopper of the crusher. Raw Material Grinding Adopts vertical grinding system. Burning System; Pulverized ...

Clinker Crusher Process

Clinker Crusher Process. 2 The limestone is combined with clay iron ore and sand It is then ground in a crusher and fed into 3 Next the fine powder is heated as it passes through the PreHeater Tower into a large kiln In the kiln the powder is heated to 1500oC This creates a new product called clinker which resembles pellets about the size of marbles

Clinkerization

The process of clinkerization signifies conversion of raw meal into clinker minerals mainly consisting of C4AF(Aluminoferite), C3A(Aluminite), C2S(Belite) and C3S (Alite) phases along with small percentage of free lime CaO, MgO, Alkalies, Sulphates etc. The conversion taking place in kiln system as raw meal is heated gradually to clinkerization temperature (1450 0 C) as shown below in table 1 ...

Clinkers and Portland Cement Manufacturing Process

2. The limestone is combined with clay, iron ore and sand. It is then ground in a crusher and fed into. 3. Next, the fine powder is heated as it passes through the PreHeater Tower into a large kiln. In the kiln, the powder is heated to 1500oC. This creates a new product, called clinker, which resembles pellets about the size of marbles.

Cement Plant 5000 Tons Of Clinker Production Line ...

One, 5000 tons of cement clinker production line configuration Cement production line is mainly composed of a set of raw material grinding, rotary kiln, cement mill, dust collector, cooling machine, preheater, crusher, feeder and other equipment, processing of cement needed raw materials are limestone, clay, iron ore, gypsum, fly ash and slag.

Clinker Crush Machine

Clinker crusher process We provide you with all accessories of mining machinery and equipment produced by our company, with complete models, reliable performance, stability and durability. Ensure the first time to meet customer parts replacement needs, reduce customer downtime maintenance time. Get Price . Clinker Crusher Hotel Omrays. Clinker Crusher is a common crushing equipment in .

(1)How to Improve the quality of cement kiln clinker?

· Improve the quality of cement kiln clinker should control the five major aspects. The fist major aspect: In order to ensure the implementation of the rotary cement kiln batching program and the uniformity of the raw material composition, improve the quality of clinker, in the production process quality control should pay attention to the mountain to improve the quality of rotary cement kiln ...

Clinker Crusher Lanzhou Production

lanzhou jaw crusher CLINKER CRUSHER LANZHOU PRODUCTION. lanzhou crusher yellow pages grinding mill china the gulin product line,consisting of more than 30 mac. Toggle navigation. TYSERVICE Provide professional solutions. Home; Ball mill; Contact Us; LM Vertical Mill. 18/09/2015; 10 Comments; Super User ; 3 Tags; High drying efficiency, Low running cost, Good environmental effect. LM Vertical ...

Building clinker production in Nepal for Palpa Cement ...

03/02/2021 · Building clinker production in Nepal for Palpa Cement Industries Pvt Ltd. 3 February 2021. After years relying on clinker imports, the Nepalese cement industry is now seeing rapid expansion of its domestic clinker production capacity. Among those building new production facilities is Palpa Cement Industries Pvt Ltd, who have recently installed ...

Clinker Crush Machine

Clinker crusher process royalcrescentgroupls rotary clinker crusher kartarpublicschoolgome solutions fls rotary clinker crusher process messebo cement a few meters away from the quarry there is one fls hammer crusher which can crush get infolive chat chat with sales. Read More; Clinker Crushing Plant . Cement clinker grinding plant ement clinker grinding plant may be the last step of ...

Industrial Solutions polytrack clinker cooel r

Integrated roller crusher ... all aspects of the clinker production process and can help you maximize the output and availability of your existing equipment. Additionally, we offer customized training courses to instruct operators in the safe and efficient use of the cooler. Facts Aeration Field of appliion Capacity Typical area load Width load Clinker bed height Installed Operation Grey ...

Clinker Crusher Process

Clinker Crusher Process. clinker grinding process Clinker grinding mill for slae by used clinker grind line in china . Clinker Mill is the key equipment for grinding after the crush process and it is widely used in Learn More clinker for a cement plant sale crusher equipment Cement. Get Price . Heavyduty Roll Breaker Efficient clinker crushing with. Heavy duty crusher 3 Don't let your ...

CEMENT PRODUCTION AND QUALITY CONTROL A. Cement ...

together with clinker produced from kiln. In this unit there are three crushers few meters away from the quarry; two Limestone/Shale Crushers (one for Line 1 and One for Line2) and one Additive/Corrective Crushers common for both lines. Line1 limestone/shale crusher reduces 85% of the size of the quarried raw material from 1000mmx1000mmx1500mm size to <=25mm while Line 2 Limestone/Shale ...

CEMENT CHEMISTRY AND CLINKER MICROSCOPY

A 4week modular course designed to give the course attendee a solid understanding of the cement chemistry and clinker microscopy. Cement microscopy is a valuable technique for examining clinker, cement, raw materials, raw feed, and coal. Every stage of the cement manufacturing process can be improved through the use of a microscope. Most cement microscopy is done using a petrographic ...

Latest Posts

- مجموعة البناء كسارة المنطقة

- كسارة تهتز الصناعية الجرانيت

- المحمولة آلة طاحونة جوز الهند مصر

- ترغب في بيع كسارة أجزاء

- شركة آلة تكسير الحجر الرملي في مصر

- خام الحديد كسارة في ولاية كارناتاكا المملكة العربية السعودية

- شركة التعدين المحجر في السودان

- المعدات في تعدين الذهب المطلوبة من السودان

- الفك ومخروط كسارات في الجزائر

- الطين محطم الصين

- بودرة التلك ماكينة كوريا الشمالية

- مطحنة التعدين الكرة للبيع

- خام الكروم محطة لدرجة

- كسارة مخروط كسارة الزركون معدات التجهيز

- أفضل آلة كسارة الصخور في مصر

- Disadvantages Of Mill Factories

- Portable Limestone Crusher For Sale Angola

- Automatic Stone Crusher In Congo 2019

- Mill Prices In South Afr

- Ton Per Day Hammer Mill

- Mesin Jaw Crusher Kapasitas Ton

- Poringa Comic Mill Hentai

- Limestone For Ball Mill

- And Zinc Mine Raymond Mill

- Where To Buy Branches Crusher In Kenya

- Molino Vertimill Solo

- Used Mobile Mini Rock Crusher

- Slag Crushing Equipment Supplier From Fiji

- Advanced Cold Bending Forming Mill

- Dx 200 Willey Grining Machine