Internal Mechanics Of Ball Mills

Internal Mechanics Of Ball Mills

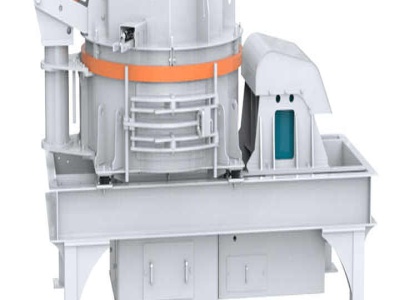

Ball Mill Internal Structure. Internal mechanics of ball mills Henan Mining A treatise on the internal mechanics of ball tube and A treatise on the internal mechanics of ball tube and rod mills Horace Edgar Rose Ralph Major additives angle appears approximately ball charge ball diameter ball mill ball wear batch mill calculated aracting centre of gravity chapter chert coefficient of ...

Ball Nose Milling Strategy Guide

· Ball Nose Milling Without a Tilt Angle. Ball nose end mills are ideal for machining 3dimensional contour shapes typically found in the mold and die industry, the manufacturing of turbine blades, and fulfilling general part radius properly employ a ball nose end mill (with no tilt angle) and gain the optimal tool life and part finish, follow the 2step process below (see Figure 1).

The ball mill as a means of investigating the mechanical ...

The Ball Mill as a Means of Investigating The Mechanical Failure of Dental Materials Abstract Objective: The main purpose of this paper is to present a new method of predicting clinical performance using mechanical loading in a ball mill. Methods: A series of four experiments (two involving a hybrid composite and one each on orthodontic brackets and bands) is described in which the ball mill ...

internal internal mechanics of ball mills

internal internal mechanics of ball mills,lscrusher Heavy Industry Technology is a jointstock enterprise that mainly produces large and mediumsized series of crushers, sand making machines, and mills, and integrates RD, production and sales. he company regards .

Milling Cutter

Ball milling cutter; Now let's discuss one by one in brief: 1. End Milling cutter: End mill cutters are the type of cutters used in the milling which has teeth at the end or at the face of the circular disk. This type of cutter is mostly used with the vertical mill machine. An end mill cutter should be selected which has the geometry and cuttingedge angle compatible with the job (workpiece ...

Design Method of Ball Mill by Sumitomo Chemical Co., Ltd ...

To predict ball mill grinding behavior using the discrete element method, we must first be able to reproduce the balls' motion in the ball mill using simulations. Kano et ) have made it clear that it is possible to reproduce the ball motion when the solid material is also present in a tumbling ball mill without fins by pro viding a suitable coefficient of friction for the balls and ...

Ball Milling

Planetary ball mills 9 . Vibration Mills 10 . Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm Final fineness: ~ 5 µm Setting of vibrational frequency: digital, 3 30 Hz (180 1800 min1) Planetary Mills 12 . 13 Planetary Ball Mill PM 400 Feed material: soft, hard, brittle, fibrous (dry or wet); Material feed size: < 10 mm ...

Mechanisms: Lead Screws And Ball Screws | Hackaday

· Ball Screws. While lead screws deliver great performance for many appliions, they are not without their disadvantages. Their main downside is mechanical inefficiency. A lead screw typically ...

Lagrangian Mechanics

Lagrangian Mechanics Generalized Coordinates A set of generalized coordinates q1,...,qn completely describes the positions of all particles in a mechanical system. In a system with df degrees of freedom and k constraints, n = df−k independent generalized coordinates are needed to completely specify all the positions. A constraint is a relation among coordinates, such as x2 +y2 +z2 = a2 ...

internal mechanics of ball mills

diagramatic design of a ball mill showing its internal and . 3 Feb 2012, Among all top down approaches, high energy ball milling, has been widely exploited for the synthesis of various, Ball Mills, PM 400[28] Several researchers have designed their own high energy, external magnetic field whose intensity and direction can be adjusted, depends on the internal mechanics of the specific mill, the

internal view of ball mills in netherlands

internal mechanics of ball mills . Ball mill external appearance and internal view Ball mills are filled up to 40 with steel balls with 30–80 mm diameter which effectively grind the ore The material that is to be ground fills the voids between the balls The tumbling balls capture the particles in ballball or ballliner events and load them to the point of fracture . More Details. Reference ...

DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR ROLLER ...

mill stops, but special internal lifters will return these balls when the mill is restarted. The large centre openings in the diaphragm and in the outlet contribute to an overall very low pressure drop across the UMS mills. Principle of Operation In ball mill, ball has to be charged around 3032% in first and second compartments.

Mechanical Milling: a Top Down Approach for the Synthesis ...

· In addition to the above mills, several other mills such as a single large ball in a vibrating frame mill[32], rod mill[33], modified rod mill[34] and other specially deigned mills[35] have been used for MM. The energy of the milling media depends on the internal mechanics of the specific mill, the power supplied to drive the milling chamber, the composition, size, and size distribution of the ...

MECHANICAL INTEGRITY TESTING (MIT)

Mechanical Integrity (MI) Part 1 Internal Mechanical Integrity 40 CFR §(a)(1) Part 2 External Mechanical Integrity 40 CFR §(a)(2) Mechanical integrity. (a) An injection well has mechanical integrity if: (Internal) (1) There is no significant leak in the casing, tubing or packer; (b) One of the following methods must be used to evaluate the absence of significant leaks under ...

The In's Out's of Ball Nose End Mills

· Ball nose end mills, also known as full radius end mills or ball mills, are cutting tools where the nose radius is equal to half of the diameter of the tool. This creates a constant single radius (or ball) at the tool end with no straight edge (sharp corners) in the profile. They are used for a host of milling operations from contouring and profiling to slotting and corner picking. Their ...

Lagrangian Mechanics

Chapter 6 Lagrangian Mechanics Generalized Coordinates A set of generalized coordinates q1,...,qn completely describes the positions of all particles in a mechanical system. In a system with df degrees of freedom and k constraints, n = df−k independent generalized coordinates are needed to completely specify all the positions.

Advances in Mechanical Engineering 2021, Vol. 13(2) 1–12 ...

· However, the ball mill load is difficult to measure directly. Therefore, the accurate recognition of ball mill load has become the focus of researchers. In the grinding process, the vibration signal generated by ball mill contains useful information related to internal load parameters, which can be used to deter

Mechanical Milling

Different kind of mills are suitable for grinding, mechanical alloying and mechanical milling such as horizontal mills (tumbler ball mill), stirred mill (attritor, Szegvari attrition mill 1), planetary ball mill, vibrating mill (tube vibrating mill, Sweco vibrating mill and shaker vibrating mill ( Spex is .

internal mechanics of ball mills

Ball Mills Mechanics Hebammen The internal mechanical ball mill of ensp0183ens ball mill receives semiautomatic ball mill or silver mill product ball mill for controlled final grinding, and generates flotation feed of uniform size ball mill The initial diameter of the steel ball is 510 cm, but it is gradually worn with the grinding

MECHANICAL INTEGRITY TESTING (MIT)

Mechanical integrity. (a) An injection well has mechanical integrity if: (Internal) (1) There is no significant leak in the casing, tubing or packer; (b) One of the following methods must be used to evaluate the absence of significant leaks under paragraph (a)(1) of this section: (1) Following an initial pressure test, monitoring of the ...

Latest Posts

- لفاف محطم في الدولوميت سحق

- trituradora de cono europa

- مطحنة بنجيلاسان على الخيط

- خام النحاس وحدة غسيل

- المصنعين الناقل التعدين في الجزائر

- مطحنة الكرة للتعدين للبيع السودان

- مطحنة أسمنت الغرفة

- بيع كسارات الحجر كسارة مخروطية

- تستخدم مطحنة الكرة دنفر

- الكسارات مبادئ العمل

- آلة صنع الرمل الجيري للبيع

- كسارة ركام صغيرة سودانية

- قوة حصان مطحنة المطرقة

- مطحنة مطرقة ذهبية تستخدم forr للبيع في العراق

- معنى مطحنة عمودية

- Crushing Mobile Crusher Schematic

- Screen Crusher Selection Criteria

- Raymond Crusher Belize

- Gravel Quarry In Ternate Cavite

- What Machine Is Used To Grind The Sand In The Sand

- List Of Quarry In Nassarawa State Nigeria

- Sa Sand Campony Business Plan

- Gold Miner Seeking Loans

- Price For Quarry Hydraulic Crusher Meter

- Stone Crushers Manufacturers In Pune

- Crusher Coal Youtube

- Forece Analysis Of Stone Crusher Machine

- Mahad Al Dahab Mine

- Industrial V Belts Industrial Heavy Duty V Belts V Belt

- Erpillar Gold Mining Dredge