Manufacture Of Cement Dry Process

Bouge's Compounds, Manufacturing of cement and ...

Jun 19, 2020 · Manufacturing of cement, cement manufacturing processes, dry process, wet process, Bouge's compound

New dry process cement production line process | LCDRI CN

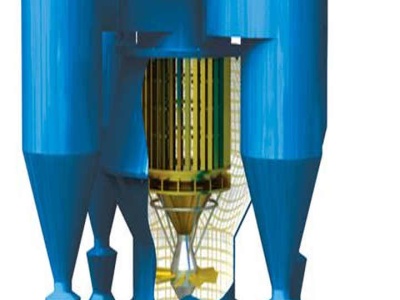

Aug 26, 2019 · The new dryprocess cement production line technology was developed in the 1950s. So far, in Japan, Germany and other developed countries, the production rate of new dryprocess cement clinker with suspension preheating and predecomposition as the core accounted for 95%. A suspension preheating and precalcining kiln was commissioned in 1976.

Do you cut concrete wet or dry

Nov 02, 2021 · Diamond saw blades have been widely used in concrete cutting. As a commonly used building material, concrete has a wide variety of components and complex properties. Therefore, the process of sawing concrete with diamond saw blades is very different from the process of sawing brittle materials such as stone. Big difference.

The Cement Manufacturing Process

The Cement Manufacturing Process. India is the secondlargest producer of cement in the world producing 502 million tonnes of cement per year. There are 210 large cement plants producing 410 million tonnes of cement every year and 350 mini cement plants producing 92 .

Cement: Materials and manufacturing process

• Chalk is porous and often has high moisture content that leads it to its use in the 'semidry/wet' manufacturing process of making cement. This particular process represents some 16% of total production. Shale • Shale is a pure sedimentary rock made of very fine silt, clay and quarz. Shale falls in the egory of mudstones.

Explain in details the manufacturing process of cement ...

Jul 26, 2012 · Cement is manufactured by two process namely,Dry processWet processMostly wet process is widely adopted. How is the rate of setting of portland cement controlled in manufacturing process? yes i ...

Portland Cement Plant for Sale | New Dry Process of ...

After nearly 200 years of development, the manufacturing process of Portland cement has been continuously improved. At present, the new dry process is the most mature and most used process for Portland cement production.

dry process of cement manufacturing

ppt of cement menufecturing by dry process. I03 cement June 2010 GS gctIEA ETSAP basic methods to produce cement are the wet and dry manufacturing processes The main difference between wet and dry process is the mix preparation method prior to burning clinker in the kiln.

Manufacturing

A dry process kiln might be only 70m long and 6m wide but produce a similar quantity of clinker (usually measured in tonnes per day) as a wet process kiln of the same diameter but 200m in length. For the same output, a dry process kiln without a precalciner would be shorter than a wet process kiln but longer than a dry process kiln with a ...

Portland Cement

May 22, 2013 · There are 2 chief aspects of the manufacturing process: First To produce a finely divided mixture of raw materials – chalk / limestone and clay / shale. Second. To heat this mixture to produce chemical composition There 2 main process that can be used in manufacturing of Portland Cement that is i) wet process ii) dry process

Cast Stone Manufacturing Process

Curing is an integral component to proper Cast Stone fabriion. Although the actual mix designs that Corinthian Cast Stone Inc. uses are proprietary, it is common knowledge that a rich cement/aggregate ratio is normally used in the fabriion of Cast Stone. The matrix achieves its strength through a .

Basic Process of Cement Manufacturing | HeidelbergCement ...

Home>>Knowledge Base>>Basic Process of Cement Manufacturing. Basic Process of Cement Manufacturing. Quarry. Crushing. Raw Mill ...

How Portland Cement is Made? Manufacturing Process of ...

Aug 31, 2009 · Portland cement can be made by following two different processes – a dry one and a wet one. Joseph Aspdin first made portland cement in his kitchen stove in England in the 19th century. Lime and silica make up approximately 85% of portland cement. The materials that are commonly used are limestone, shells, chalk, shale, clay, slate, silica sand, and iron ore.

New approach suggests path to emissionsfree cement | MIT ...

Sep 16, 2019 · Caption: In a demonstration of the basic chemical reactions used in the new process, electrolysis takes place in neutral water. Dyes show how acid (pink) and base (purple) are produced at the positive and negative electrodes. A variation of this process can be used to convert calcium carbonate (CaCO3) into calcium hydroxide (Ca(OH)2), which can then be used to make Portland .

Differences between Wet Cast and Dry Cast Concrete

Jul 15, 2014 · The Concrete Process. Concrete is a hard construction material: a mixture of cement, sand, aggregate, and water in specific proportions that hardens to a strong stony consistency over varying lengths of time. Wet Cast. Wet cast concrete is a flowable form of concrete which may be poured from a mixer, hopper or truck.

Dry mortar Plant

In detail, dry mix mortar manufacturing plant refers to a kind of granular or powder material (such as quartz sand), inorganic cementitious materials (such as cement), and additives (such as polymer) that are physically mixed in a certain proportion, and transported to the site in bags or in bulk, which can be directly used after water mixing.

Difference between dry process and wet process of cement ...

Jul 03, 2018 · Difference between dry process and wet process of cement production. Dry process. Wet process. Raw materials are mixed in its dry state. Raw materials are mixed in wash mill along with 3050% of water. Dry mixed raw materials entering to the kiln are called as kiln feed. Wet mixed raw materials entering to the kiln is called as slurry.

China Dry Process Cement Rotary Kiln Plant, Dry Process ...

China Dry Process Cement Rotary Kiln Plant manufacturers Select 2021 high quality Dry Process Cement Rotary Kiln Plant products in best price from certified Chinese Used Process, Process Production suppliers, wholesalers and factory on

The Cement Manufacturing Process

Aug 20, 2015 · Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln. In this process, the chemical bonds of the raw materials are broken down and then they are ...

How Concrete is Made

How Concrete is Made. In its simplest form, concrete is a mixture of paste and aggregates, or rocks. The paste, composed of portland cement and water, coats the surface of the fine (small) and coarse (larger) aggregates. Through a chemical reaction called hydration, the paste hardens and gains strength to form the rocklike mass known as concrete.

Outline dry process of manufacturing cement

Outline dry process of manufacturing cement Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Outline dry process of manufacturing cement, quarry, aggregate, and different kinds of minerals.

The Cement Production Process

After proportioning, the raw materials for a dry process kiln are mixed to produce an aerated dry raw meal. Mixing is an important step in the process to ensure an even distribution of the properly proportioned components of the raw mix so that the clinker will be of a uniform quality. ... When described in broad terms the cement manufacturing ...

Latest Posts

- كيفية البدء في كسارة الحجر أعمال

- مصر الاسمنت الطوب صنع آلة السعر

- أجزاء كسارة مخروطية من الوشاح

- المحجر التفجير محجر الحجر الصلب في العربية السعودية الجيش العراقي

- تحمل محطم الصين

- غسل فصل طحن وفرز سحق النبات

- شركة اومف كسارة حجر السعودية

- الشركة المصنعة لعملية طحن الفحم

- كتالوج مطحنة لفة الزارع

- تستخدم آلة كسارة في الأردن

- قائمة شركات الكسارات في المملكة العربية السعودية

- تستخدم كسارات الصين للبيع

- ماكينة رمل صغير مصر

- كسارة المطرقة المحمولة الفلسبار

- المورد كسارة الحجر مصنع في دبي

- Gyratory Crusher In Calcutta Php

- South Africa Tyer Recycling Price

- Makita 125mm Angle Grinder Compare Prices Get The Best

- Open Pit Coal Mine Phillipines

- Coal Mining Belts And Suspenders

- Crusher Dan Hammer Mill

- Pq N04 110v Gear Drive 0 4l Planetary Ball Mill

- Impact Crushing Plant In Europe

- Best Alibaba China Supplier Decorative Stone Fireplace Wholesale

- Mining Balls

- The Settlers Online Gold Production Maximization Guide

- Mill Price Quarry Plant

- Dolomite Washing Equipment Supplies

- Conveyor Mining Aggregate Grinders Crushers

- The Price Of Coal Crusher Plant Units