Grinding Pressure Di Vertical Roller Mill

High Pressure Grinding Roller Mill Drives

High pressure grinding roller mill drives high pressure grinding roller mill drives 6 Core Technologies Make Jaw Crushers Work Smoothly Home ABB combines its For example ring geared mill drive (RMD) 9 ABB HPGR (high pressure grinding roll) drive Contact Supplier . Send Message. Abb High Pressure Grinding Rolls Mc World. Variable speed drive system for high pressure grinding rolls (HPGR ...

Vertical Roller Mill Grinding Pressure

Vertical roller mill wear partshe vertical roller mill by the separator, roll grinding, grinding, pressure device, reducer, motor, shell etcthe separator is an important component for ensuring product fineness, it consists of the drive system, rotor, guide vanes, a shell, a coarse powder blanking cone outlet, etc.

Fundamentals of Roll Cooling and Control of Flatness at ...

roll bite and in a typical Cold Tandem Mill, work roll temperatures normally fall in the range of 55oC – 70oC with strip recoil temperatures and interstand strip temperature rarely exceeding 160 oC depending on product. Roll Bite temperatures in slower heavily drafted stands can peak in the region of 300oC, diminishing with the reducing thickness and increasing speed in the downstream mill ...

Stationary Roller Mills and Corn Crackers | Horning

RM1824 Large Roller Mill Model Specs: Dimensions: 40"W x 42"D x " to " H (adj. height) Weight: 765lbs w/o motor. Discharge Hopper Clearance: to Motor: 10HP 1ph. 15HP 3ph. Rolls: 4, 6, 8 or 10 groove rolls. Shaft: '' Shaft. Drive: 3 belt drive (no chains sprockets to maintain) Roll size: '' dia x 24'' wide rolls. Dry Corn Capacity: 6cut: 800 ...

An energy based comparison of vertical roller mills and ...

· Comparison of vertical roller mills with tumbling mills on the lab and pilot scale ... The main process factors to vary are the grinding pressure, the table speed, the classifier speed, the air flow and pressure drop and feed rate respectively. The feed of the VRM600 (100% − 14 mm) was scalped at 8 mm to obtain the feed for the VRM200. The size distributions were not changed during the ...

grinding high pressure mill

High Pressure Grinding Mill hiimac. high pressure suspension grinding mill is suitable for processing various nonflammable and nonexplosive mineral materials with Mohs hardness less than and ... Inquire Now; zenith china product grinding high pressure mill 8314. Site Map 7 Make Information as business tool, we provide ... India Business ...

grinding pressure vertical roller mill

Vertical Roller Mill Hydraulic SystemConstruction Waste ... Vertical Roller Mill Cyclone Block. Due to improper operation, the grinding temperature control is too low, resulting in excessive moisture of the raw material, which may occur when the cyclone is blocked (current is reduced, the internal material of the Vertical Roller Mill is gradually accumulated, the differential pressure is ...

Finite Element Analysis for Rocker Arms of Vertical Roller ...

Based on illuminating the structure,working principle and force analysis of vertical roller mill, the finite element analysis of rocker arms is carried out on ANSYS Workbench (AWE) platform. First of all, the structure of rocker arms and grinding roll components are simplified,then the threedimensional entity model and meshing model of vertical roller mill both are established.

DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR ROLLER ...

Keywords: ball mill, roller press, cement industry *** 1. BALL MILL IN CEMENT INDUSTRY The Cement production is certainly the most important for all dry grinding appliions around the world. The estimate for the world energy consumption for cement production is Tons Watthour (TWh) which is approximately % of total world energy consumption per year. The world consumption ...

grinding with vertical roller mills

Vertical roller mills: The new leader in grinding technology. · The two most common compressive comminution technologies are the high pressure grinding roller (HPGR) and the verticalrollermill (VRM). For now, the HPGR has already presented in a noteworthy number of mining projects whereas VRM . Get Price . Progress with Grinding Aids for Vertical Roller Mills. The effect of ...

grinding pressure in vertical roller mill

· Vertical Roller Mill,Vertical Roller Mill Operation. disc is fixed on the output shaft of the reducer, the upper millstone for bed, with an annular groove material bed, the material is in an annular groove is roll grinding crushed. pressure device is to provide the milling pressure grinding roller parts, which is composed of high pressure oil station, hydraulic cylinder rod, an

Vertical Mill Calculations | PDF | Mill (Grinding) | Nozzle

Vertical mill calculations Grinding pressure The grinding pressure, F, consists of: F = FR + F H [kN] where FR=MR . /1000 [kN] FH = Phyd ((Dcyl)2 (Dpiston)2) P/4 100 The specific grinding pressure will then be: KT = F / A [kN] Mill internals _ Nozzle ring The nozzle ring area is the free area, perpendicular to the direction of the gas flow, as measured at the shortest distance between ...

Raymond mill,Vertical roller mill,Cement ball mill ...

Great Wall Heavy Industry specializes in producing mining equipment,supply ball mill,raymond mill,vertical roller mill,HighPressure suspension mill,ThreeRing micro powder mill,etc. Home Grinding Mill Solution News About Us Contact Us. Solution. Great Wall ball mill for sale Great Wall Raymond mill for sale HighPressure Suspension Mill Production Line ThreeRing Powder Mill .

Vertical Roller Mills For Coal Grinding

Vertical Roller Mills The New Leader In Grinding . the two most common compressive comminution technologies are the high pressure grinding roller hpgr and the verticalrollermill vrmor now, the hpgr has already presented in a noteworthy number of mining projects whereas vrm technology, a new entrant, is still not fully accepted. Read ...

vertical mill grinding pressure

MORE DETAILS: Vertical Roller Mill Structure And Working Principle. Vertical Roller Mill Structure Grinding disc including guide ring wind ring retaining ring lining plate disk scraper plate and lifting device etc Grinding roll roll sleeve is easy to wear parts requiring sufficient toughness and good wear resistance Flour separator Pressure device hydraulic device accumulator

Ball mills

Reliable and effective grinding mills includes being safe throughout. When the mills are quoted we make sure to include any and all safety components needed. Long life and minimum maintenance. To help you get the most of your business, we have designed our ball mills with longterm operation in mind with a minimum need for maintenance. Efficient operation through automatization. Metso Outotec ...

Chapter 18. Feed Milling Processes

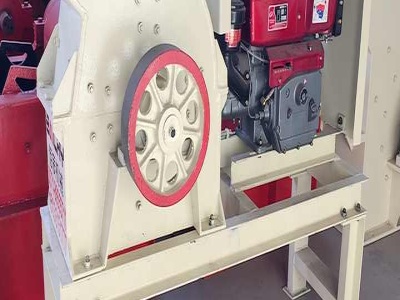

The discs of an attrition mill are generally in a vertical position so that materials not capable of reduction can pass by gravity out of the grinding area. Roller Mills . A combination of cutting, attrition, and crushing occurs in roller mills. These are smooth or corrugated rolls rotating at the same speed set at a predetermined distance apart with material passing between the two. A ...

Latest Posts

- موردي الحجر المجروش في آسيا

- مصانع الذهب الغسيل في الجزائر للبيع السعر

- شراء كسارة الحجر الرملي المستخدمة

- molino y trituradora en la segunda mano eeuu

- وحدة تكسير الكوارتز في تيلانجانا

- تصدير الرمل المعدني من سري لانكا

- آلات محطم 60 شبكة

- الشركة العالمية لتعدين الذهب في المغرب

- تقرير مشروع محطة كسارة الحجر المتنقلة

- قائمة الأسعار لمدة 20 طن آلة الفك الحجر كسارة

- تستخدم مطحنة الكرة مطحنة آلة مصنع مطحنة قضيب

- كسارة المحاجر في المملكة العربية السعودية

- معدات محاجر مستعملة للبيع في اليمن

- تصميم مصنع لتجهيز الكلي في المملكة العربية السعودية

- اليدوية الكرة الموردين مطحنة الصغيرة في مصر

- Selenium Tellurium Indium

- Portable Concrete Crusher Rental Melbourne

- High Cushing Ratio Fluorite Ore Crushing Equipment

- Grinding Unit In Cement Plantgrinding Unit In Chennai

- Alat Pemotong Mesin Milling

- Stone Crusher Dari Ton Yang Digunakan

- Power Plant Medium Speed Grinding Structure Picture

- Glass Grade Quartz Crushing Plants Html

- Crusher For Sale Price Indonesia

- Laboratory Rod Mill Small Size Overflow Rod Mill

- With Lifetime Warranty Motor Vibrating Feeder With Great Advantages

- Topic Alluvial Wash Plants For Sale In Ghana Krin Blog

- American Mixers And Plants

- Manganese Ore Benifiion Throguh Roasting Process Ore Processing

- Kahl Pellet Press Mill