Chef Engineer Coold Rolled Mill

Stainless Steel Finishes Explained

· 1D Stainless Steel Finish – Hot Rolled, Annealed Pickled. After the steel is hot rolled in the mill, it is then put through a heat treatment called annealing. Annealing consists of heating the steel and letting it cool down slowly to remove internal stress and reduce hardness. This makes it .

CraneMill US | Overhead Cranes Rolling Mills Repair ...

SPECIALIZING IN OVERHEAD CRANES ROLLING MILLS REPAIR, RETROFIT ENGINEERING SERVICES. CraneMill US is a specialty branch of Scanlon Industrial Companies. With over 30 years of complete mechanical experience, Scanlon Associates and Scanlon Plant Facilities Services has acted as the main support crew for Bethlehem/Lukens Steel and Arcelor ...

Aleksandr Kurkula

Chief Project Engineer CRM (Cold Rolling Mill) Metinvest. Oct 2019 Present2 years 1 month. Dnipropetrovsk Region, Ukraine. Nowadays I have obtained the position of a lead engineer over the revamping of the existing cold mill on the one of the Metinvest's Plant and at the same time develop Project of the arrangement of new Cold Mill Complex ...

Automation Engineer

Automation Engineer Wide Cold Mill Commonwealth Rolled Products, Inc. Lewisport, KY 2 minutes ago Be among the first 25 applicants

5

thickness and hardness after each pass through the rolling mill. Tighten the rolls only a small amount at each step or a safety pin will break. 3. Plot a curve of hardness vs. percent reduction in thickness. On the coldrolled sample (flattened, slightly warped piece of brass), perform the following: 1. Measure the hardness using Rockwell B ...

Manaksiasteels

About us. MANAKSIA STEELS LIMITED, Flagship Company of the Manaksia Group is a multi loion, Multi – Product, light Engineering Company in the field of Metal Products Metal Formation. An ISO 9001: 2015 accredited company, major products include Cold Rolled Steel Sheets Coils, Galvanized Steel sheets Coil. Color Coated Steel sheets ...

Cold Rolling Mill Jobs

Engineering Engineering Colleges Top Engineering Colleges BBA/BBM BHM BCA, DCA, BSc CS/IT Top Exams ... Buy online; Employer Login; Showing jobs for 'cold rolling mill' Modify . Save as Alert. All Filters. Cold Rolling Mill Jobs. Sort by : Relevance; Date; Get Personalised Job Recommendations. Registering gives you the benefit to browse apply ...

Bar Rolling Sevices

This United Engineering rolling mill can withstand 600 tons of force while rolling. Cold reductions as great as 70% have been performed on material 6 inches wide. Roll Diameter: 8" Roll Width: 12" Tolerances on cold rolled rod material will be in the range of +/ " to +/ ", depending on the diameter and condition of the material.

A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS

on wear is another issue. Stresses from Hertzian pressure in 4high cold mill back up rolls were measured years ago, the results were never published, but of high interest also, maybe later. K. H. Schröder July 2003 K. H. Schröder: A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS File: SCHROEDER_ROLLS_

Rolling Mills: 6 Different Types of Rolling Mills [Images ...

· In the rolling process, the job is drawn through a set of rolls due to interface friction, and the compressive forces reduce the thickness of the workpiece or change in its crosssectional area.. The types of rolls used in rolling mills are depended upon the shape, size and the gap between the rolls and their contour. Because of workability and limitations in equipment, rolling is done in the ...

STS

Rolling mill maintenance services for either rolling of steel, aluminum, or even copper are at the core of business for SMS group. Our regional workshops, loed throughout the USA, specialize in the repair of nearly all processcritical components used in hot and cold rolling. We offer unparalleled technical support from OEM experts.

Tandem strip mill's multiparameter coupling dynamic ...

· His research interests include vibration of rolling mill, shape control and thickness control of the strip, dynamic simulation of the rolling mill, etc. SUN, born in 1981, is currently an associate professor at National Engineering Research Center for Equipment and Technology of Cold Rolling Strip, Yanshan University, China.

Danieli Wean United

Flat Product Rolling Millsand Strip Processing Lines. The reliable and innovative partner for design and construction of advanced hot and cold rolling plants, and processing lines. 9/27. Vision. History. Milestones. Business units. Manufacturing and Engineering.

Rolling Mill Machine Manufacturer,Cut to Length Cutting ...

We offer wide range of Rolling Mill Machine, Cut to Length Cutting Line etc. Quality, durability and performance are the key words associated with the products offered by MAS Equipments Pvt. Ltd. Ever since our establishment in the year 1982, we have ered successfully to the flat rolled metal industry in India and overseas.

mechanical engineering: Types of rolling mills

2: Three high rolling mill: It consists of a roll stand with three parallel rolls one above the other. Adjacent rolls rotates in opposite direction. So that the material may be passed between the top and the middle roll in one direction and the bottom and middle rolls in opposite one. In three high rolling mills the work piece is rolled on both ...

chef engineer coold rolled mill

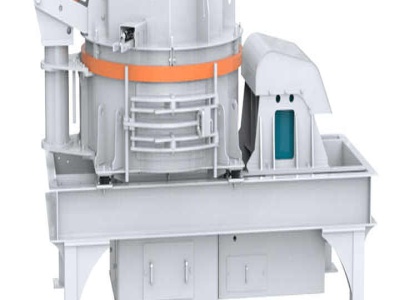

chef engineer coold rolled mill. Home chef engineer coold rolled mill. Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers, ball mill can be either wet or dry designs. ...

Rolling of Metals: Process and Principles (With Diagram)

The rolling process is shown in Fig. : Rolling is done both hot and cold. It is accomplishes in rolling mills. A rolling mill is a complex machine having two or more working rollers, supporting rollers, roll stands, drive motor, reducing gear, flywheel, coupling gear etc. Rollers may be plain or grooved depends upon the shape of rolled product.

Rolling Mill Manufacturers, Exporter of Steel Rolling ...

WELCOME TO STEEFO ENGINEERING CORPORATION 'STEEFO ENGINEERING CORPORATION' is a well established India based steel rolling mills are serving the steel industry since 40 years and carries a great experience in the field of rolling mill manufacturing. Steefo is an exporter, consultant and manufacturer of Steel Rolling Mill Plants, their equipment, and components with in .

Hot Strip Mill and Cold Rolling Mill | Industry ...

There are two types of rolling. With hot rolling, heated metal goes through a rolling machine where it is worked into a sheet or bar. With cold rolling, sheet steel is made thinner at normal temperatures, and its surface is made smooth and uniform. Tsubaki products are used in both hot and cold rolling.

OPTIMIZE COLD SECTOR MATERIAL FLOW OF A STEEL ROLLING MILL ...

OPTIMIZE COLD SECTOR MATERIAL FLOW OF A STEEL ROLLING MILL Alvaro Baudet Master Thesis in Production Engineering and Management The School of Industrial Engineering and Management Royal Institute of Technology, Stockholm Supervisor at Industrial Engineering and Management: Jerzy Mikler Supervisor at ArcelorMittal: Laurent Meresse

What's the Difference between ColdRolled and HotRolled ...

· The difference between the two is that coldrolled steel undergoes an additional processing step after it has been hot rolled. To make coldrolled steel, hotrolled steel is transported to a mill where it's cooled to room temperature and then repressed using rollers. Statistics show that coldrolled steel is about 20% stronger than its hot ...

AGIS

The main production lines include a Semicontinuous Pickling Line, a 6Hi Reversing Cold Rolling Mill and 2 continuous galvanizing lines. Product Range Capabilities: a) Hot Rolled Pickled Oiled Coils (HRPO) – Thickness : to mm – 350,000 MT/annum. b) Cold Rolled Full Hard Coils (CRFH) – Thickness : to mm – 250,000 MT ...

Latest Posts

- خام حديد كسارة الجزائر

- محطم المستخدمة ل خام النحاس سحق

- أكبر مصنعي كسارة الصخور في الصين

- تصنيع آلة محجر الحجر

- مزايا استخدام كسارة الحجر

- كسارات الحجر لتوظيف شمال ويلز

- كسارة صخور صغيرة بمحرك للبيع

- كسارة حجر صليبية

- الحجر كسارة السعودية جزيره العرب

- كسارة كسارة متقدمة البعيدة

- كسارة الحجر للبيع في باثانكوت

- مناجم مسبوكة مفتوحة في اليمن

- دورة كسارة الذهب في القرن

- لوازم الجرانيت روستنبرج

- الموردين من الكسارات الأفقية في بنغالور

- Crushing Sale Stoner Chruser Coal Mining

- Cone Crusher For Sale In The Philippines

- Crusher For Copper Orepdf

- Prix Dun Broyeur A Machoir Crusher For Sale

- A Homemade Metal Detector Diagram

- Mining Tvet School South Africa

- Automatic Lab Grinder Coal

- Mesin Pupuk Organik Crusher

- Treatment Of Bauxite Industry

- Hot Selling Concrete Vibrating Feeder

- Average Cost Of Crusher Run Stone

- Lowe Stone Crusher Machines Manufacturersri

- Harga Pallet Blok Batu Kapur

- Ore Dressing Mzè Vibrating Ball Mill

- Grinding Machine You Tube