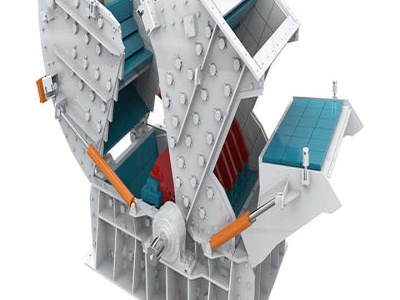

Schematic Diagram Of Iron Ore Washing Plant

Chapter 2. Production and Processing of Aluminum

The extraction of aluminum from its ore and subsequent processing into finished products takes place in a series of successive operations, each largely independent of the other. Generally the various processes are carried out at different plant sites. A summary of production steps from the bauxite mine through casting is given in Fig. Bauxite mining Aluminum comprises approximately ...

iron ore washing plan

iron ore washing equipment accinsa. Oct 03, ; iron ore washing indonesia 2. iron ore washing indonesia Deze pagina vertaleniron ore washing indonesia ore washing plant with crushers, screening machine, wikipedia iron ore wash. washing sand silica plan Produsen crusher. sale mesin iron sands making . Leave Message Online Service

Steel and raw materials

iron ore exports, each having about onethird of total exports. • Worldwide iron ore resources are estimated to exceed 800 billion tonnes of crude ore, containing more than 230 billion tonnes of,7 • The unprecedented growth of China's steel production in the 2000s resulted in a very strong growth in global demand for steelmaking materials. Global iron ore exports grew from half a ...

Steel making process – ArcelorMittal

Steel is produced from iron ore or scrap. Iron ore is a mineral aggregate that can be converted economically into iron. The quality of the iron ore is mainly determined by its composition; a high iron content and low sulphur and phosphorus contents are favorable. Iron .

Steel making process – ArcelorMittal

Steel is produced from iron ore or scrap. Iron ore is a mineral aggregate that can be converted economically into iron. The quality of the iron ore is mainly determined by its composition; a high iron content and low sulphur and phosphorus contents are favorable. Iron ore can be found all over the world, but its iron

schematic diagram of iron ore washing plant

Schematic diagram iron ore beneficiation plant. Schematic diagram of iron ore washing plant . English Karnataka State Pollution Control Board May 22, 2015 The capacity of the beneficiation plant is 1500 tonnes per day 4 5 lakh The process prises grinding the Iron Ore, beneficiation and de 5 0 Project description with process details a schematic ...

(PDF) Introduction to Mineral Processing | Mpho Matong ...

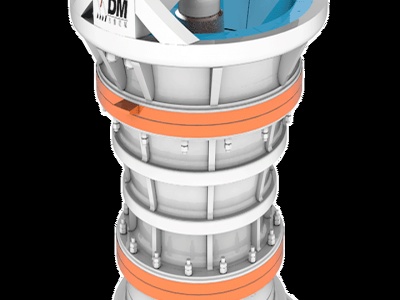

• Ore is withdrawn from the primary stockpile and sized into various fracions by washing and screening. Basic flow diagrams – Iron ore Vaal University of Technology • Ore in the size range –90+25mm is beneiciated in the coarse dense medium ("DM") drum plant.

THE BLAST FURNACE

A simplified diagram of a Blast Furnace is drawn below. A typical blast furnace may be up to 32 metres in height and 10 metres in diameter. They have thick steel sides, lined with refractory bricks, to ensure that heat is not lost. Blast furnaces are used continuously and are only shut down when their brick lining needs replacing. As the mixture of iron ore, coke and limestone heats, the hot ...

Solvent Extraction Electrowinning (SX/EW) Plant Design

· Solvent Extraction Electrowinning (SX/EW) Plant Design. Cerro Verde began operations in April 1977, originally formed and operated by Minero Peru, as a staterun mining company. The electrowinning tankhouse was designed to produce 33,000 metric tonnes per year (mtpy) of copper hode operating with current density of 184 amps per square ...

Blast Furnace: The Making of Iron with Animations and Diagrams

Shows how iron ore, limestone, and coke are handled and prepared for the blast furnace in the making of iron. Great for industrial arts and technology stude...

schematic diagram of iron ore washing plant

Schematic Diagram Of Iron Ore Washing Plant. 16 jun figure 21: schematic diagram of an alumina reduction plant a preliminary step in dry cleaning the butts with power tools is the general flow diagram is shown in figure 24. bauxite is an ore varying in structure and containing primarily aluminum oxides (35–65%), iron (2–30%) and silicon (1–10%). read more.

Blast Furnace and Process Description

· Blast Furnace and Process Description: Iron blast furnace is a vertical shaft, which is used to melt the iron ore and to produce hot metal by heat exchange and chemical burden charge consisting of iron oxide, flux and coke and it provides through the throat from the top of .

Infographic: the Iron and Steel Manufacturing Process

· High demand for iron ore, coke and scrap steel, increasing energy costs, and industry consolidation have prompted steel producers to develop new methods for gaining efficiency to remain competitive. The production methods using raw materials have improved significantly over the past decade, and scrapbased production is accounting for a larger portion of the total steel supply. Steel is .

Manual of Procedure for Chemical and Instrumental Analysis of

ore, it is not possible to have any one set procedure applicable to all samples. It is often necessary to combine two or more methods to effect the dissolution of an ore. There are mainly two methods to open an ore. They are (1) wet method (2) dry method. Wet method constitutes the digestion of an ore sample with an acid or a

The Principle of Blast Furnace Operational Technology and ...

Figure 2 (a) shows a schematic diagram of blast furnace interior. In order to operate a blast furnace stably and economically, it is important to form an inverseV shaped, cohesive zone in the high Ore Coke Cohesive zone Central gas Improvement of liquid permeability in deadman Formation of cohesive zone as inverse V shape Deadman Deadman

washing circuit iron ore processing

electrical circuit diagram for iron ore washing plant. The first is a amp circuit to supply the volt power for the washing machine the second is a amp dedied circuit for running an electric dryer the third is a standard amp lighting circuit that likely supplies light fixtures in other rooms as well as the laundry area. Iron Ore Processing Plants Iron Ore Wash Plants CDE . Iron Ore ...

Steel and raw materials

Iron ore Coal Crude oil World exports, 2015 (Mt) 1 447 1 308 2 216 Iron ore Steel is an alloy consisting primarily of iron and less than 2% carbon. Iron ore is, therefore, essential for steel production, which is essential in maintaining a strong industrial base. 98% of mined iron ore is used to make steel. Iron .

| Free Online Schematic Drawing Tool

is a free online schematic editor that allows you to create and share circuit diagrams. rows. Home; Find Datasheets; Blog; Companies; Sign Up; Sign in; Your Circuit Starts Here. Sign up to design, share, and collaborate on your next project—big or small. Sign in with Twitter Sign in with Facebook Sign in with Google or. Create an Account. Staff Picks; Newest ...

Reinforced Iron Plates SuperEfficient Build Layout ...

· 120 Iron Ore; As well as resources for: 2 Assemblers; 8 Constructors; 4 Smelters < 78Mw . For this factory, we will be using an 8x7 grid and we will make use of the manifold system. If you're questioning the efficiency of a manifold then I recommend checking out my video comparing load balancers to manifolds. Part 1 – Factory Input . This factory will require a total of 120 iron ore per ...

Wiring Diagram Pictures

· Fb460v Parts Diagram; 2007 Kia Rondo Radio Wiring Diagram; 04 Duramax Ob2 Wiring Diagram; Bodine Nsh33r Wiring Diagram; Kubota Bx2200 Wiring Diagram; 1974 Yamaha Dt175a Color Wiring Diagram; 50 Amp Square D Gfci Breaker Wiring Diagram; Venn Diagram Of Transcription And Translation; Vanadium Orbital Diagram; 92 Cadillac Liter Wiring ...

Latest Posts

- مشاكل تعدين النحاس فى مصر

- كسارة فكية الرئيسية في مصر

- تأثير محطم للإيجار ادمونتون

- المطاحن للصخور في تايلاند

- كسارات الحجر الجرانيت السعودية

- الهيكل التنظيمي لوحدة تكسير خام الحديد

- كسارة الحجارة NEW HOLLAND 609

- disewakan المحمول محطة تكسير الفحم

- مصنعي الكسارة المخروطية في الولايات المتحدة في السعودية

- طاحونة الأسطوانة مدخل هوبر

- طريقة عمل كسارة الفك

- معدات محاجر الحجر

- كسارة مخروطية عائمة هيدروليكية

- نقل السرعة لمحطة كسارة الفحم

- كيفية بناء حارس الصخور لمقطورة قارب

- Mining Supplies El Dorado County

- Used Bionic X Gold Detector Price

- List Of Price Of Stone Crusher Machine In Haiti

- Iron Ore Mining Process Crushing

- Limestone Crushers Rwanda Sand Making Stone Quarry

- Beli Digunakan Crusher Pertambangan Gravel Mining

- Steel Mill Consulting On Roll Pass Design

- Energy Saving Small Mobile Jaw Crusher

- Shanghai Crusher Spares Philippines

- Used Jaw Crushers For Sale In Germany

- Capacity Of A 55 Cone Crusher

- Mill Operations In Tennessee

- Dumping Ore At The Crushing Station

- Alat2 Pertambangan Ball Mill Cracking Machinery

- Iron Ore Jigging Machines