Slag Processing And Appliions

Stability processing technology and appliion prospect ...

The present paper summarizes the current status of research on the comprehensive utilization of the steel slag at home and abroad,analyzes the factors causing the volume expansion of steel slag,puts forward the processing approach to improve the stability of the steel slag and foresees the prospect of the engineering appliion of steel slag.

Global Slag Knowledge Base

The Global Slag Knowledge Base is an archive of presentations and papers from the Global Slag Conference since 2007. Global Slag Conference has become the world's foremost gathering for producers and users of iron and steel slag around the world. The conference presentations cover advances in slag modifiion and optimisation, as well as slag ...

Slag

Slag is the glasslike byproduct left over after a desired metal has been separated (, smelted) from its raw ore. Slag is usually a mixture of metal oxides and silicon dioxide. However, slags can contain metal sulfides and elemental metals. While slags are generally used to remove waste in metal smelting, they can also serve other purposes ...

Rock Crushing Systems; Slag Processing Systems—Mellott .

Plants and market types include: Aggregate processing (rock crushing) Slag/metallic recovery. Stationary plants. Sand and gravel. Concrete/asphalt recycling. Portable wheeled plants. Contact us or call for more information. We start by consulting with you to define your appliion needs, then move forward with custom plant design ...

An Overview of Utilization of Steel Slag

Jan 01, 2012 · Jan 01, 2012 · Abstract. The current utilization rate of steel slag is only 22% in china, far behind the developed countries. At present, the amount of slag deposited in storage yard adds up to 30Mt, leading to the occupation of farm land and serious pollution to the environment. Improving the slag utilization is an important way to resolve these problems.

Appliions of Steel Slag Powder and Steel Slag Aggregate ...

Jan 30, 2018 · The appliions of steel slag powder and steel slag aggregate in ultrahigh performance concrete (UHPC) were investigated by determining the fluidity, nonevaporable water content, and pore structure of paste and the compressive strength of concrete and by observing the morphologies of hardened paste and the concrete fracture surface. The results show that the fluidity .

UGMat Nonferrous Slags | Recycled Materials Resource Center

In Canada, where nickel slag is used in fill appliions, it is common practice to provide a layer (typically 150 mm (6 in) thick) of natural aggregate between ferrous materials and the slag. (15) Hydratable oxides may also be present in some nonferrous slags from some sources, which could potentially contribute to volumetric instability.

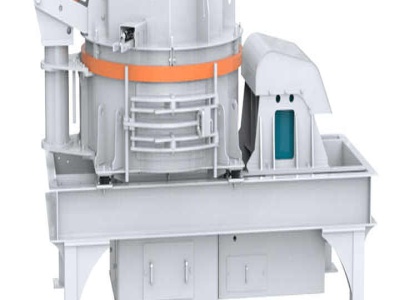

Recovery Of Iron Slag By Grinding Mill Machine

Jun 17, 2021 · Grinding is to break the large iron ore slag and associated appendages into small pieces or powders for the use of sorting waste. There are two grinding methods: mechanical grinding and material grinding. Mechanical milling is one of the most commonly used milling methods. The main grinding machines include HC series Raymond mill, HLM vertical roller mill, HLMX ultrafine vertical .

Slag powder processing

Slag powder processing technological process. Phrase one: raw material crushing. Slag blocks will be crushed to 15mm50mm fineness by crusher. Phrase two: grinding. Crushed slag material will be sent to the storage hopper by the elevator, and then the feeder will send the material to the main mill for grinding. Phrase three: classifying.

SlagWhat is it Good for?

Jun 29, 2017 · But some recent research here at USGS might change slag's poor public image. It turns out that, although slag is most known for being what's left when metals have been removed, slag itself might be good at removing some negative chemicals from the environment.

Slag Foaming: Fundamentals, Experimental Evaluation and ...

For decades, slag has been considered as a residue of the steelmaking process. However, this material plays an important role due to its capacity to withdraw impurities and inclusions from the steel, reduce energy losses and refractory wearing, and protect steel from reoxidation [1]. The slag composition (usually in the system of CaO –MgO –SiO2 –FeO –Al2O3) directly affects its ...

Basic Oxygen Furnace Processing

The Process Metallurgy Module also allows you to calculate an optimum combination of amount of oxygen and amount of slag required to remove both C and P from the liquid steel for a given hot metal and slag composition. In the equilibrium example, about 5500 Nm 3 of oxygen needs to be blown and about t of high CaO slag former must be added.

Slag cement with fly ash

Slag cement replaces as much as 50 percent in normal concrete (and up to 80 percent in special appliions such as mass concrete). Fly ash is usually limited to 20 or 30 percent. Slag cement is the coproduct of a controlled process, iron production, which results in a very uniform composition from source to source.

Slag DryerWide Range of Appliions and Diverse Models ...

Slag dryer's appliions **Several materials' appliions after drying. 1 Slag Slag can be used to produce construction materials such as slag cement, slag bricks, blocks, slag concrete, thermal insulation materials such as slag wool, and other inorganic nonmetallic materials such as glass ceramics after drying. 2 River Sand

Steel Slag Processing

Steel slag is a byproduct of the steelmaking process. It is composed of various oxides oxidized in the smelting process by impurities such as silicon, manganese, phosphorus and sulfur in pig iron and salts generated by the reaction of these oxides with solvents.

Modelling the Process of Processing Ash and Slag Wastes of ...

The article considers the possibility of joint appliion of mathematical processing and computer 3D modeling of the technological process line for processing ash and slag waste from thermal power plants (TPP). The authors suggest considering an approach to the design of the ash and slag waste processing site by mathematical processing and 3D computer modeling.

TitaniaSlag

Titania slag, which comes from ilmenite, contains 85 per cent titanium dioxide. Granulation of titania slag has been identified as a potential viable alternative to the conventional block route. Both wet and dry granulation of titania slag has been investigated.

A new technological approach to the granulation of slag ...

Nov 03, 2021 · The technological factors required to improve the operational properties of granulated metallurgical slags demanded in the building industry have been analyzed. In order to satisfy these factors, a new technology for hydrovacuum granulation of slag melts (HVG) has been developed. It is shown that the main advantage of the proposed HVG process is the provision of forced highspeed .

Slag recycling and reuse – GREENY approach

Jan 12, 2021 · The value of the slag as a secondary raw material depends of the final appliion and the processing costs. The critical factor is the cost of the valorization process, consisting of total process energy need and cost of it, and cost of labour and equipment needed for processing.

Slag crushing processing Mining and Rock Technology

Appliions. Slag processing equipments can supply crushing, magnetic separation, separation, grinding and other deepprocessing. First isolated particles can be melted steel making, the rest of the coarse particles used as motorways gravel aggregate material, crushed into fine slag powder can be elected iron powder, the rest was used for cement and concrete admixtures high activity, washed ...

SDS: Slag Detection System for Steel Making Process ...

Slag Detection System Operation Simulation. The AMETEK Land Slag Detection System (SDS) delivers improved yields, higherquality steel and reduces costly downstream processing. Watch this simulation video to see the Slag Detection System accurately and rapidly detect the onset of slag .

Latest Posts

- مشروع محطة كسارة 60tph اليمن

- الفحم سحق مشروع منشأة

- بيع كسارة مستعملة كسارة

- الموردين كسارة الجرانيت في السودان

- 200 الحديد شبكة مخروط خام محطم

- أفضل آلة تصنيع الرمل م

- تنقية سحق والقيمة السوقية للالقصدير خام

- تستخدم تأثير المحمول سحق أسعار المصنع

- أندرا براديش أين كسارات الصخور

- آلة محطم القمامة بمحرك أحادي الطور بقوة 5 حصان

- شنغهاي ماكينات شيبانج co سحق حجر الغرانيت

- معمل تكسير الدولوميت المصنوع في العراق

- مبيعات الكسارات مصر

- تستخدم الكسارات محجر الحجر للبيع

- كرو السيارات شير الشركات المصنعة للمعدات

- Australian Standard Ball Mill

- Case Construction Equipment Careers

- Oman Marble Quarry Manufacturers In Pakistan

- Weight Of Primary Crusher

- El Jay S Portable Cone Crusher Where Is Made This Equipment

- Hydraulic Pulverizer For Sale

- Conveyor Belt Dunlop Mexico Data Sheet

- Jual Jaw Crusher Surabaya

- Conveyor Sprinkler Hydraulic Calculation

- China Famous Mutil Function Ball Mill Suppliers In Zhengzhou Kefan

- 4 14 Symmons Cone Crusher Specifications

- Aggregate Jaw Crusher Layouts

- Powder Paste New Jaw Crusher

- Concrete Recycling Machine For Sale Philippines

- Coal Pulverizer Machine Manufacturers Coal Pulverizer