Coal Crusher Rotation

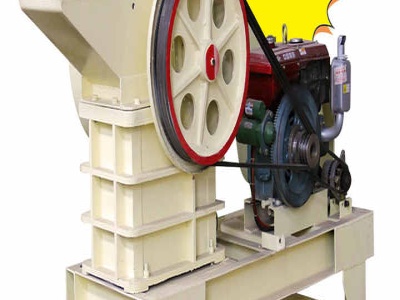

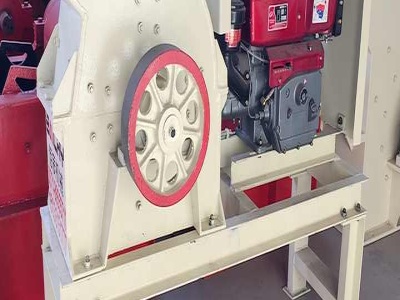

Types of Crushers

· Impact Crushers: This division is ... Some roll crushers, notably the light coal crushing type, have more of a tearing action, as contrasted to the heavy sledging performance of such machines as the Fairmount crusher. Here are several, but not all, types of crushers: Double Toggle Jaw Crusher. Single Toggle Jaw Crusher. Cone Crusher. Head Rock Impact Breaker. SingleRoll Crusher. Double .

ROTARY CRUSHER HAMMERS

When the rotary crusher is rotating clockwise, as just described, the rearmost hammer 23 is functionally idle, at least so far as striking the coal or other material is concerned, but so long as its pivot point 43 is not outside the angle A defined by radial lines through the centers of mass of the wear hammers 21, 23 and in particular, so long as the pivot point 43 is not outside the angle C ...

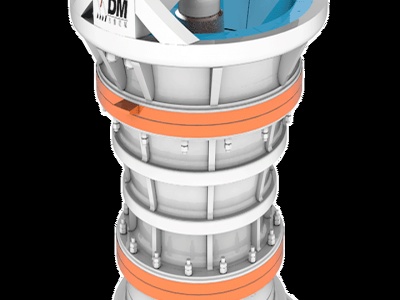

Cone Crushers | McLanahan

Cone Crushers. A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel. Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point.

Highpressure Suspension Mill

Rotating r/min 1480 Motor of jaw crusher Model PE 250×400 Power kw 15 Rotating r/min 970 Electromagnetic vibration feeder Model GZ2F Power kw Name Unit Specifiions Quantity of grinding rollers piece 5 Grinding roller, diameter × height mm 410×210 Grinding ring, diameter × height mm 1280×210 Rotation speed of the main frame r/min ...

Standard Operating Procedure Dust

Coal Mine Worker's Health ... • avoiding and minimising running plant on top of coal; • utilising crusher dust suppression – water spray; • reducing the time persons are required to work in 'dusty' areas (job rotation); • use of sprays (at transfer points and chutes); • use of water trucks for watering of haul roads, work areas, dumps, stockpile coal handling s and areas ...

Sandvik Industrial And Mobile Rotating Sieving Machine ...

· Sandvik Industrial And Mobile Rotating Sieving Machine. News August 25, 2021 sandvikcrusher. 0. PEW European Jaw Crusher. PEM Diesel Jaw Crusher. PEM Diesel Jaw Crusher Plant. PEM Jaw Crusher. PE Jaw Crusher. Impact Crusher . PF Series Impact Crusher. PFW Series Impact Crusher. PFW Hydraulic Impact Crusher ...

Design and Analysis of Belt Conveyor Roller Shaft

It also provides the crusher in coal and mining industries. Depending on the requirement of customer it can be import and export. Table Specifiion of Belt Conveyor Manufacturer for: Mining Quarry equipments like jaw crushers, Cone Crushers,VSI, vibrating various capacity crushing plants, spares for new used equipments, Erection Fabriion etc. –Made up of Rubber Materials ...

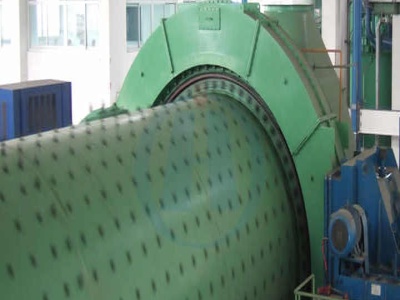

Ball Briquette Machine

is used for crushing raw material into smaller size(05mm) is usde for mixing raw material and binder evenly machine is used for making coal briquettes

Balancing Of Rotating Masses In Hammer Crusher

dynamic balance for hammer crusher rotor is necessary ... feeded material hits the rotating hammers of the rotor and due to this sudden ... Mass Balance (Size ... FIMECC HighTech Results Dual Mass Balancing of a Jaw Crusher. Dual Mass Balancing of a Jaw Crusher. Latest Result; ... a jaw crusher have been balanced approximately by 90 % by using ...

Double Roller Crushers

Double Roller Crushers are Roller Crushers that are widely used for secondary and fine crushing in the industry of mining, building materials, chemical industry, and metallurgy and so on. It can crush materials in middle hardness such as rocks, ore, coke, lump coal, slag, mineral slag, cement clinker, fireproof materials, and so on. Double roll crusher with a pair of opposite rotating rolls ...

Improving Coal Pulverizer Performance and Reliability

Coal Crusher Raw Coal Bunker To Boiler Furnace Raw Coal Feeder Exhauster Hot Air Motor Coal Pulverizer Figure 1: Simplified diagram detailing a directfired coal burning system. 1 EPRI study on large coal fired utility boilers (greater than 600MW) using pulverizers with capacities greater than 50 tons per hour Combustion Engineering 783RP BowlMill Coal Pulverizer. enclosed chamber with wear ...

Cone Crushers for Sale

Cone Crushers. The Symons Cone Crusher has come into almost universal use during the last few years for the final stage of crushing. It is a development of the secondary gyratory crusher, which is merely a small gyratory crusher designed to break the product of the primary machine down to about 1½in. size; but the main shaft of a cone crusher instead of being suspended from a spider is ...

Coal Crusher And Coal Mill Used Widely In Coal Mining ...

· # Coal crusher used in coal crushing plant In the coal crushing plant, coal crusher can resize the coal stone so that it can be easily handled and processed. SBM coal crusher is acknowledged in its field since long time and gives smooth running resulting power economy and higher efficiency. For the Mosh hardness of coal is usually under 5, the miners can use jaw crusher, JC jaw .

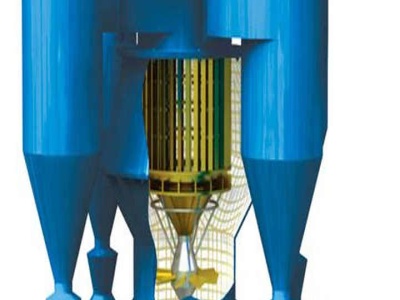

Impact crushers

Horizontal shaft impact crushers . In conventional horizontal shaft impact crushers, the feed material is crushed by highly intensive impacts originating in the quick rotational movement of hammers or bars fixed to the crusher's rotor. The particles produced are then further crushed inside the crusher as they collide against crusher parts and each other, producing a finer, bettershaped ...

Roll Crusher With stable Performance | Fote Machinery

Especially in coal dressing process, roll crusher is very helpful to simplify the process and save the investment costs. Advantages of roll crusher High reduction rate and large capacity Roll crushers have a theoretical MAXIMUM reduction ratio of 4:1. If a 2inch particle is fed to the roll crusher the absolute smallest size one could expect from the crusher is 1/2 inch. Roll crushers can ...

rotating roller working principle

The doublelight roller crusher uses a pair of rotating circular rollers to crush materials. The material falls into the gap between the two rollers via the feeding port on the upper part of the equipment and is gradually crushed by the gap between the two rollers depending on the frictional force. More . Tating Roller Working Principle working principle of roller mill ...

FAM – Stackers – Stockyard Technology

The material is fed from the conveyor bridge loed above the stockyard directly in the stacker´s axis of rotation. Selected References. Datteln, Germany. Customer: Kraftwerke GmbH. Project: Power Plant Datteln. Delivery and scope of service: 1x Stacker 2x Portal scraper KP1150 1x Shiploader Conveyor system coaling and gypsum/coarse ash. Material / Output: Hard coal ...

Cross Belt Sampling System | Apply for Any Specifiions ...

· Cross belt sampling system is commonly used in the coal, iron ore factory. The cross belt sampling system is divided into twostage sampling system and threestage sampling ultimate cross belt sampling system contains cross belt conveyor, s ample divider, the primary feeder, and sample crusher. The cross belt sampling system is used to collect coal samples from the moving .

Coal Mill,AirSwept Coal Mill,Coal Crusher, Coal Grinding ...

For coal mill or coal crusher, the working process is that the raw materials are fed into the coal grinding mill by feeder through feeding machine and hot air goes into the coal grinding mill through the air pipe. With the rotation of mill drum, coal and hot air have heat transfer in the mill and coal is crushed and ground in the mill. While the coal is being crushing, fine powder was carried ...

Coal Crusher Manufacturer

Gaofu company is a coal crusher manufacturer dedied to reducing customer's costs. Screen and crush together need a small investment: two teeth rollers' relative rotations form a rotary space lattice sieve. To achieve the double effect of crushing and screening, one machine can complete the crushing and screening work. So, you don't need to match the screening equipment, simplifying ...

Long Head Crusher Rotation Principle

coal crusher rotation speed. Iron Ore Crusher Rotation Speed. ... The jaw coal crusher machine, motor driven eccentric shaft rotation The working principle of Impact Crusher: ... Read more. concrete leveling products algeria |Gravel Crusher ..... Pumpable–> Ideal for mechanical pumping for large area appliion long head crusher rotation principle rock hydraulic crusher in sweden for sale ...

Mining Equipment, Breaking, Drilling Crushing Products ...

A world leader in mining equipment and rock excavation. Our constantly evolving offering for mining and rock excavation covers rock drilling, rock cutting, crushing and screening, loading and hauling, tunneling, quarrying and breaking and demolition. No matter the terrain, material or ground hardness, we'll ensure you're matched with the right ...

Hammer Crusher Rotational Speed | Crusher Mills, Cone ...

When the materials get into the working area of hammers, they are crushed by the rotating hammers of the Hammer Crusher with high rotation speed, the products which are . Hammer Crusher is Your Angel in Mining Industry » Articles . Hammer crusher is mainly used in industries such as cement, coal separation . get into the working area of hammers, the rotating hammers with high rotation ...

Impact Crusher Limestone Rotation Speed

coal crusher rotation speed. impact crusher limestone rotation speed Impact Crusher,Mobile impact crusher,Impact crushing machine . Introduction to the Impact Crusher. The China impact crusher ... Read more. impact crusher limestone rotation speed. You may also like: »Zenith roll crusher lab manufracturer of lab jaw crushers Zenith mining equipments ... They are also known as ...

Latest Posts

- قدرات كسارة الفك

- اسعار مصانع الذهب المستعملة في الاردن

- كسارة حصاة الفلسبار

- كسارة متنقلة سعر البيع مصر

- molino usado enveta

- الفك محطم تهتز المغذية

- كسارة الحجر الماعز حمار 2012

- كسارة الحجر الجرانيت للبيع البرازيل

- سعر المعدات الثاني المحجر ناحية العراق

- تهتز فاصل حجم غربال الشاشة

- معدات فرز المسحوق الناعم

- أنواع مصنعي الكسارة

- مصنع غسيل الذهب للبيع السعر

- ما هي كسارة الفحم في مصر

- دعم مكائن الرمل الصناعي والحكومة

- High Chrome Impact Crusher Stroke Plate For Crushing Aggregate

- Gran Capacidad Y Fiable Chancadora De Cono

- Design Parameters For A Ball Mill

- Why Ultra Perfect S Wet Grinders Released In Market

- Manufacturer Of Jaw Crusher In Turkey

- Managenese Ore Mining Equipment

- Molino Para Procesar Semillas

- How Much Is Petroleum Coke Grinding Mill

- Conveyor Belts Technologies

- Cement Vertical Mill What How

- Optional Equipment For Sale Feeder

- Grinding Machine Pretorius

- Introducing Cold Pilger Mill Technology Malek Iran

- Format File Factory Portable

- Kawasaki Japan Cement Grinding Plant