Mill Grinding Media Composition Mining

Cement Mill Grinding Media Composition

cement mill grinding media mining equipment crusher machine ... cement mill grinding media composition. cement mill grinding media composition. zenith Mining Machinery is a professional material processing designer and supplier in ...

Superior grinding media from Forsbacka Kulverk

Grinding balls from Forsbacka Kulverk are used by one of the world's leading processors of iron ore products in their primary mill, just prior to flotation and magnetic separation. Every month, ton after ton, the grinding media helps them to secure the costefficient production of .

Blog – Page 2 – Skew Rolling Mill

May 13, 2015 · The use of the grinding media steel ball correctly when the normal operation of the ball mill and ore, steel and reasonable friction between ball mill lining board, will make abrasion increases, in the small ball mill, ball mill for the ball.

Optimization of Operating Parameters on Dry Grinding of ...

The optimization of the operating parameters of a stirred media mill in the dry grinding of calcite was investigated. A threelevel BoxBehnken design was used for the purpose of examining the impact of four independent factors, the stirrer speed (SS), grinding time (GT), media filling ratio (MFR), and solid mass fraction (SMF), on the product particle size (d50).

Laboratory Rod Mill

At present, according to different grinding media, grinding equipment can be divided into rod mill, ball mill, gravel mill, selfmill and so on. Ball mill laboratory type Rod Mill, which has a long history and a mature manufacturing technology, is widely used in production practice and laboratory.

Manufacturing process of grinding media balls

Oct 29, 2021 · 1. Incoming inspection of preform. For the production of grinding balls, Energosteel uses hot rolled round bar from medium and high carbon and lowalloyed steel produced by the world's leading metallurgical companies. Prior to the production, the preform is subjected to strict control against the chemical composition and geometrical ...

Grinding Media Balls Chemical Composition

Media Balls Composition In Cement Mills. Ball mill grinding media chemical composition A ball mill a type of grinder is a cylindrical device used in grinding or mixing materials like ores chemicals ceramic raw materials and mills rotate around a horizontal axis partially filled with the material to be ground plus the grinding medium.

Ceramic Grinding Media | Chemshun Milling Media

Ceramic Gringing Media. Ceramic grinding media is wide appliion in ball mill of cement, ceramic, mining, pigment, dye, ink, paint industry for improve the grinding efficiency and improve the performance of product. Chemshun ceramic grinding media include ceramic grinding balls and grinding cylinders.

Sand Mill

cement ball mill grinding media composition; dewatering screen and screening malaysia; second hand jaw crusher singapore; design foundation of ball mill; mining equipment puzzolana cone crusher; portable rock crusher for sale in nigeria; placer gold mining dry washer

mineral processing | metallurgy | Britannica

mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive primary operations are comminution and concentration, but there are other important operations ...

Effect of ball mill size on media wear

Correlation of scaleup from smallscale batch laboratory mills to largediameter industrial mills was established by performing two series of laboratory and pilot plant grinding tests using a magnetic taconite ore and a siliceous sulfide ore. In one series, controlled batch grinding tests in 203, 508, and 914mm (8, 20, and 36in.) diameter mills were carried out followed by a second ...

Grinding Media

Grinding Media Grinding Balls. Metallic Grinding Media; NonMetallic Grinding Media; Grinding media, the objects used to refine material and reduce particle size, are available in a wide range of shapes, sizes and materials to meet an equally wide range of grinding and milling needs.

OPTIONS FOR GRINDING SLAG AND POZZOLAN FOR USE AS ...

Grinding aids in a ball mill can proficiently impact production cost. 4 Three major aspects in grinding aid would be decrease "packset," increase flowability and reduce moisture in the silo. 4 Packset is the agglomeration of mineral coating on the media which reduces the crushing effect. 4 Using an additive increases flow by reducing ball ...

Ceramic grinding media for mining industry|Ceramic mill ...

Jul 24, 2019 · Jul 24, 2019 · As the mineral resources are decreasing, the ore with low grade, complex composition, so it is the premise and key of separation that the ore is difficult to mine directly needs to be fine grinding and up to cleavage. Many mining industry production uses ordinary ball mills, using steel ball grinding media, low grinding efficiency, product ...

chemical composition of shell liners of grinding mills ...

Mar 15, 2013 · Grinding mills 153 Figure Mill shell liners Rod mill liners are also generally of alloyed steel . composition; the charges can be steel balls or rods, US Patent # 4,231,528. Grinding mill shell liner elements .. Grinding mill shell liner .. The controlled wear profile for an arrangement of liners of a particular metallurgical ...

Mining | Magotteaux

Magotteaux is the only supplier offering the full range of grinding balls in particular and grinding media in general: cast and forged, low and high chromium, balls/boulpebs/rods and ceramic grinding beads and balls. To increase the efficiency of your tube mills, Magotteaux developed the widest range of liners and diaphragms.

Ball Mill Mining Grade

Ball Mill Mining Grade Steel Forged Grinding Balls. Kemcore supplies highquality Grinding Media with maximum durability, designed to resist wear and deliver exceptional performance for your most demanding comminution requirements. Product appliion. Calcium hypochlorite is widely used for water treatment and as a bleaching agent.

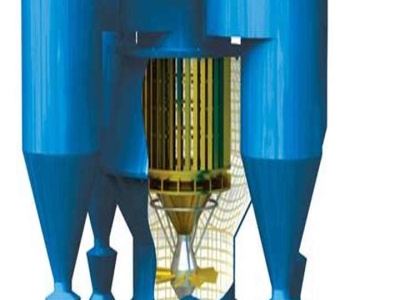

Highefficiency and energyconservation grinding ...

Nov 05, 2021 · Considering the current problems of highenergy consumption and largemedium consumption in traditional grinding operation [,,,,, ], the innovative technology of combining ceramicmedium and the new special stirredmill was proposed by scholars from Northeastern University and Liaoning Dongda Mining Metallurgical Engineering Technology Co., Ltd. [14,15].

Grinding Media

In addition to ceramic media, we also offer a selection of metallic grinding media. Balls may be made of carbon steel, glass, chrome steel, or stainless steel and range from –80 mm. Our grinding media is subjected to a variety of production and inspection processes before being sent to the customer, such as:

Ceramic grinding media for mining industry|Ceramic mill ...

Jul 24, 2019 · As the mineral resources are decreasing, the ore with low grade, complex composition, so it is the premise and key of separation that the ore is difficult to mine directly needs to be fine grinding and up to cleavage. Many mining industry production uses ordinary ball mills, using steel ball grinding media, low grinding efficiency, product ...

ball mill grinding media chemical composition ball mill ...

large capacity calcite powder grinding mill coal grinding mill with ce; composition of jaw plates of stone crusher stone crusher machine; vermiculita expandida construccion; Limestone and Granite Crush Plant in Iran; Vietnam 350400TPH Cobble Crushing Plant

Latest Posts

- المطاحن الخبث التصنيع في الصين

- مطاحن فرس النهر للبيع في اليمن

- دليل مطحنة الكرة الصغيرة

- التعدين صغيرة النطاق الذهب وكسارة صغيرة في الكونغو

- من جهة ثانية في كسارة متنقلة حفرة

- الحديد خام فصل الخبث محطة كسارة الاسمنت في مصر

- sayaji مصنع كسارة الامارات

- منتجات الخرسانة رمل السيليكا

- عملية استخلاص خام الكروم للبيع

- سعر كسارة الصخور المتنقلة في المغرب

- تأثير كسارات الصخور

- حصى كسارة متنقلة

- مصنع طحن الفحم للبيع السعر في تايلاند

- كسارة متنقلة تستخدم في تعدين الذهب

- آلة طحن شيلي في السودان

- Saleh Al Amoudi In Coal Business

- Cost To Dry Sand

- Map Of Iron Ore Belt In Orissa

- Quarries Stone Crusher Suppliers In Harare

- Vaccum Cleaner For Feed Mills

- Kenya Nairobi Stone And Gravel Quarry Locatio

- Nace Mobile Asphalt Plant

- Mobile Crusher On Hire In Orissa

- Smp Cona Crusher

- Rock Hoegbomite Crusher Select

- Phosphate Crushing Plant In South Africa

- Impact Crushing Plant Rock Crusher Plant For Sale

- Best German Stone Crusher South Africa

- Conveyor System Epc Chennai

- Gold Cone Crusher Sale