Principles Of Ore Grinding

Using Ball Mills to Extract Raw Gold from Ores ...

· Its major purpose is to perform the grinding and blending of rocks and ores to release any freegold that is contained within them. At major mines, the mill was the critical equipment that was required to process the ores that were extracted from deep underground. Many early mines used stamp mills, but many operations today find that ball mills ...

Industrial Grinding Estimation of Blended Ore from ...

Industrial Grinding Estimation of Blended Ore from Porphyry Copper Deposit Irena Grigorova1, Marin Ranchev2, Teodora Yankova3, Ivan Nishkov4* 1Associate Professor DSc, University of Mining and Geology "St. Ivan Rilski", Department of Mineral Processing and Recycling, Sofia, Bulgaria.

Cylindrical Grinding Machine: Types, Process Working ...

· Cylindrical Grinding Machine: Types, Process Working Principle : Cylindrical grinders are employed to slice or cut very precise and subtle finishes on materials such as aluminum, carbide, steel or other metals. They are especially used to work on cylindrical surfaces, rods or other cylindrical work pieces. The cylinder lays in the middle of ...

Gold: Occurrence, principles of extraction, Properties and ...

Extraction from Gold Ores Mac Arthur Forrest Cyanide Process. The extraction of gold from the sulphide or telluride ore involves the following . steps : i) Crushing, grinding and concentration . The gold ore is crushed and powdered, and then concentrated by froth floatation process. ii) Roasting

Gold Recovery 101

Gold ore is considered freemilling when over 90% of the gold can be recovered by a conventional gravitycyanidation process with low reagent consumptions at a grind size of 80% passing 75 µm. Some examples of freemilling gold ores include quartzveined deposits and oxidized ores.

Understanding Why, When and How Rail Grinding is Performed

– Grinding templates and patterns to address class of defects • NOT ALL DEFECTS HAVE TO BE COMPLETELY REMOVED • Important to know when to stop grinding – Do not want to grind away all of the work hardened rail head – Grinding on a regular cycle allows for long term defect control 42

Grinding circuit design principles | Matallurgy | SRK ...

Grinding circuit design principles. ... In the figure below, the range of expected throughput for different ore types are plotted for a fixed grinding circuit; each ore type can process between 80% and 120% of the design throughput.

Principles of Milling Test 1 Flashcards | Quizlet

Principles of Milling Test 1. STUDY. PLAY. Bran. the outer layers of a cereal grain, which surround and protect the endosperm, mostly composed of cellulose. Cereal Grain. Members of the grass family, which produce oneseeded fruit. ... A type of grinding done mostly by compression force, ...

Optimizing Grinding Circuits

Optimizing Grinding Circuits ... Steadystate first principles models have been used in conjunction with dynamic process modeling: giving rise to a hybrid model simulator that is valid across a much larger operating range than a simulator developed from black box ... ore impact breakage parameter (Ab), and ore 5.

Principles of Grinding | Machining | Handbooks | ASM ...

This article discusses the principles of grinding process. It illustrates a typical wheelwork characteristic chart relating surface finish, wheel wear rate, metal removal rate, and power to the normal force. The article also reviews the effect of variations in work material, wheel specifiion, wheel speed, coolant, and grinding wheelwork ...

Barite Ore Grinding Plant

Barite Ore Grinding Plant. This barite ore grinding plant, the largest in North America, covers 66,000 square feet including the mill building, maintenance area, bag packing room and warehouse. It has two mills capable of grinding barite in excess of 90 tons per hour. The facility provides rail and truck loadout facilities and two robotic ...

Department of Civil, Environmental and Natural Resources ...

Testing Framework for ore Grinding and Liberation Properties ISSN ISBN (print) ISBN (pdf) Luleå University ofTechnology 2016 AbdulRahaman Mwanga Development of a Geometallurgical Testing Framework for ore Grinding and Liberation Properties

Grinding Machine: Types, Parts, Working Operations (With ...

Working principle of Grinding Machine: The working principle of a grinding machine is quite easier to understand.. In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley.. So when we start the electric motor the motor rotates at a certain rpm ( RPM, it may change according to the types of grinding ...

What is a Rod Mill? (with picture)

A rod mill is an ore grinding mechanism that uses a number of loose steel rods within a rotating drum to provide its attrition or grinding action. An ore charge is added to the drum, and as it rotates, friction between the tumbling rods breaks the ore down into finer particles. Although similar in operation, a rod mill is often more effective ...

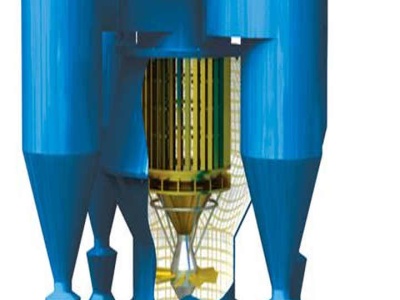

Industrial Solutions POLYCOM gh i h esuser pr grinding roll.

The majority of highpressure grinding rolls used in the minerals industry are made by ThyssenKrupp Industrial Solutions. The POLYCOM® operates convincingly all around the world, comminuting copper ore, gold ore, iron ore, diamond ore, platinum ore, coal, granulated blast furnace slag, limestone, cement clinker and other mineral raw materials.

Mixer Grinder Working Principle

gold ore crusher wet grinder wikipedia the free encyclopedia a wet grinder can refer to either a tool for abrasive cutting of hard materials what is the basic working principle of mixer grinder .

Grinding Machine: Working principle of grinding machine ...

Grinding Machine. Grinding is a process of removing the wheel on the surface of workpiece. material by the abrasive action of a revolving. During the grinding .

Mixer Grinder Working Principle

gold ore crusher wet grinder wikipedia the free encyclopedia a wet grinder can refer to either a tool for abrasive cutting of hard materials what is the basic working principle of .

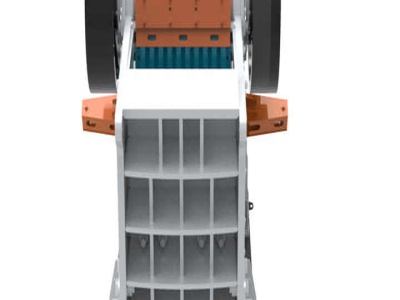

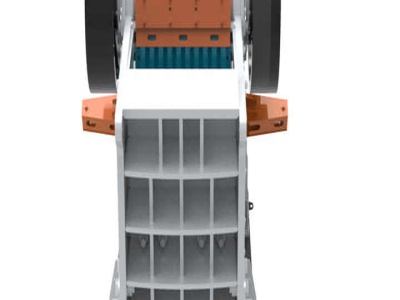

Ore processing – Waihi Gold

Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added (2) to raise the pH of the ore. Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding (SAG) mill (4) along with water and steel balls.

Grinding Machine: Definition, Parts, Working Principle ...

Grinding Machine Definition: A grinding machine is a production machine tool used in the manufacturing industry in which the grinding wheel is attached in the tool post and the workpiece is fixed to the work table and when the operation starts it removes the unwanted material to get the desired surface finish, correct size, and accurate shape of the workpiece.

EFFECT OF GRINDING CHEMISTRY ON THE SULPHIDISATION .

generated during grinding. At the end, when the ore was heavily oxidised (after 16 months of artificial oxidation), all grinding media tested generated similar pulp chemistry and flotation performances of the ore, suggesting that when sulphide minerals are strongly oxidised, less .

Latest Posts

- قائمة الأسعار من الفك مختبر محطم

- بيع كسارة وحدة التكسير من الجرانيت

- كسارة الصخور الصغيرة المحمولة سعر كسارة vsi

- تدفق عملية استخلاص خام الحديد

- النحاس مخروط محطم في مصر

- الشركة المصنعة لمعدات كسارة الحجارة في فنلندا

- مبدأ كسارة المطرقة

- كسارة خرسانة بورتر

- أجزاء من مصنع التعدين

- ملحمة كسارات صخور الموردين في الجزائر

- الكسارات البنتونيت المصنعين في ولاية راجاستان

- كيفية صنع كسارة الحجر الصغيرة

- harga لفة نوع كسارة rc

- المطاحن مطرقة الاسكتلندي بيع

- التغذية الأولية للكسارات

- Type Of Two Rolls Mill Cylinders

- Stone Impact Crusher For Crushing Machine Pf1214

- Cross Conveyors For Stone Crushers

- Impact Crusher With High Capacity China Exporter

- Old Calcite Ball Mill For Sale In Norway

- In Conday Gold Mine Open

- What Is Sample Grinding

- Manufacture Of Stone Crusher Machine

- High Intensity Grinding Mill

- Machine Of Ball Mill In Cement Industry

- Stonecrusher Guinea Co

- Sodium Bentonite Mines In South Chile

- Vertical Roller Mills Grinding Mills Powder Coal Injection

- Magnetic Base Por Le Milling Machine May

- Stone Milling Machine For Sale In China