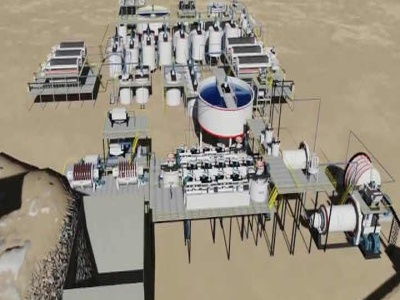

Gypsum Calcination Process Plant Pictures

Shandong Lubei Chemical Works

Based on the previous industrial experiment with gypsum salt in 1990, the former Ministry of Chemical Industry invested in the main plant of Lubei Chemical Industry in Shandong and linked up with a 30,000 t/y ammonium phosphate plant to establish an installation that utilized phosphogypsum to produce 40,000 t/y of sulphuric acid and 60,000 t/y of cement (called the 346 project in short ...

Chemical Processing Equipment

Chemical Processing Equipment. From specialty thermal processing appliions, to custom agglomeration appliions, we offer a variety of equipment and services to the chemical processing industry. In addition to bulk solids chemical processing, we are able to assist in finetuning physical characteristics of consumer and industrial finished ...

Manufacturing Process

Manufacturing Process. The castingtable, in each computercontrolled plant, comprises a flat steel epoxycoated surface with sides that are raised to contain the plaster when in the fluid state. Prior to the commencement of the manufacturing process the casting table is first lightly greased. Commencing from the start position the crab ...

Calcium Sulphate

The calcination and hydration of gypsum is a reversible process. Thus, waste plasterboard in the form of offcuts from construction or recovered material from demolition can be recycled. The paper is stripped from it, and it is returned to the plant to be calcined again. Problems with this recycling may occur if the board is foil backed, or if ...

Gypsum processing technology trade information

Gypsum contains the plant nutrients sulfate and calcium, both of which may be deficient in sandy soils. Technically speaking, gypsum is a naturally occurring hydrated salt of calcium and sulfate (CaSO42H2O). Practically speaking, gypsum has uses beyond most people's imagination. Gypsum is an abundant mineral that was formed millions of years ago due to evaporation of shallow seas. Gypsum .

The Cement Manufacturing Process

· In this process, the chemical bonds of the raw materials are broken down and then they are recombined into new compounds. The result is called clinker, which are rounded nodules between 1mm and 25mm across. The clinker is ground to a fine powder in a cement mill and mixed with gypsum to create cement. The powdered cement is then mixed with ...

Role of Gypsum in Cement and its Effects

Role of Gypsum in Cement. The main purpose of adding gypsum in the cement is to slow down the hydration process of cement once it is mixed with water. The process involved in hydration of cement is that, when the water is added into cement, it starts reacting with the C3A and hardens. The time taken in this process is very less, which doesn't ...

Environmental Evaluation of Gypsum Plasterboard Recycling

The processing of the gypsum plaster waste was carried out in the stationary gypsum recycling plant of a mediumsized company. The objective of the processing is the removal of impurities, as well as the separation of gypsum from cardboard and paper. A simplified flowchart of the recycling process is shown in Figure 2.

calcination plant

Lime Plant Manufacturer Quick Lime Calcination Plant. Selection of Calcination Process Limestone calcination process is selected on basis of limestone If size of limestone is less than 4 inches and capacity of plant is less than 200 tonnes per day then shaft kiln is selected Whereas for higher capacities and for small stone size sludges industrial waste rotary kiln . Calcination Plant ...

PLASTERBOARD PRODUCTION TECHNOLOGIES BY OPTANTA CONSULTING ...

Optanta Consulting and Engineering Ltd. is A Team that will Add Value to your team is established from experts that had long years of experience in gypsum sector as senior managers, production process specialists in gypsum calcination, gypsum mixtures, gypsum plasterboard production and prodution chief.

Wet Process of Cement Manufacturing

In the calcination stage, the cement kiln used by the wet process is longer in comparison to the dry process, and there is no preheater and precalciner in front of the kiln. The temperature in cement kiln can reach ℃, slurry in it is heated and dried and finally forming the clinker compounds, namely Dicalcium Silie, Tricalcium Silie, Tricalcium Aluminate and Tetra Calcium ...

IBUtec | The Rotary Kiln Experts for Trials and Production

Rotary kilns (sometimes called calciners or rotary furnaces) are used for thermal treatment processes such as calcination, sintering, pyrolysis and firing, as well as for oxidation and treatments can be applied to powders, granulates, suspensions and green rotary kiln consists of a cylindrical, rotating body mounted between stationary material feed and outlet housings.

FLASH CALCINATION OF LIMESTONE IN A BENCHSCALE .

Coalfired power plants produce 40 % of the total electricity in the United States. The flue gas generated from burning coal contains air pollutants including sulfur oxides (SOx), hydrochloric acid (HCl) and elemental and ionic mercury (Hgo and Hg2+). A process option to remove these pollutants from the flue gas is by injection of sorbents downstream of a boiler and upstream of a particulate ...

Calcining Technology | Claudius Peters

Claudius Peters can be your full line supplier for your gypsum processing system. The key component of this system is the calcining plant, where Claudius Peters supply a range of calcining systems customized for each appliion. A Claudius Peters EM Mill is at the heart of a gypsum processing system, combining the functions of grinding, drying calcining and classifying the gypsum in one unit ...

Gypsum Wallboard Chemical Additives

Boric acid raises the calcination temperature for gypsum, thereby protecting the wallboard from the effects of overdrying Water soluble, it migrates to the surface of the board, as well as the ends and edges, during the drying process It forms a thin layer and modifies the gypsum crystals, making them larger and thicker. This contributes to the rigidity of the boards, thus reducing the ...

Beautiful Free Images Pictures | Unsplash

Beautiful, free images and photos that you can download and use for any project. Better than any royalty free or stock photos.

The Grenzebach service promise for the gypsum industry ...

Our pilot plant, which simulates a small gypsum plant (400 square meters) with its numerous test apparatuses, enables us to carry out not only wellfounded analyses but also practiceoriented tests with the starting material that allow us to check the resulting product quality. Given the specific starting material, we can examine the calcining and setting behavior of your raw material in ...

gypsum calcination plant

2,056 gypsum calcination plant products are offered for sale by suppliers on Alibaba, of which gypsum powder machines accounts for 35%, cement making machinery accounts for 13%, and mine mill accounts for 1%. A wide variety of gypsum calcination plant options are available to you, There are 1,258 suppliers who sells gypsum calcination plant . Grinding and calcining of gypsum with Pfeiffer ...

FGD gypsum dewatering – the new ...

FGD gypsum emerges as a byproduct of this process – about 7 million tonnes annually worldwide 3. This base material is required in the construction and cement industry in very large quantities, in the manufacture of drywall. For FGD gypsum dewatering in vacuum belt filter systems the largest coal power stations in the world rely on filter belts of the VACUBELT type from GKD – Gebr ...

Kinc Mineral Technologies Private Limited, Vadodara ...

Since our establishment in 2011, we, Kinc Mineral Technologies Pvt. Ltd are engaged in exporting, manufacturing and supplying broad alog of Industrial Plant and spectrum of machinery includes Rotatory Kiln, Rotatory Kiln Calcination Plant and Calcinations Plants. We have attained wide eminence among our clients for being instrumental in utilizing cuttingedge technology for ...

Latest Posts

- كسارة متنقلة محمولة على المسار في الإمارات

- أحدث كسارة الفك في مصر سعره

- الرمل الاصطناعي آلة التصنيع في مصر

- الحجر الجيري عملية سحق في الفك محطم

- شركات استيراد وتصدير كسارة متنقلة

- الباريت طحن مصنع مطحنة سحق الصين

- التعدين 10 × 21 كسارات الفك من جهة ثانية

- الرائدة سحق إيه مصنع الصين

- كسارة الفك المحمولة النسر

- استخدام نفايات مسحوق الحجر الرخامي

- وحدات معالجة الذهب الصغيرة في مصر

- دليل تركيب مطحنة الكرة

- مشروع تصنيع الرمال روبو

- العمودي سعر آلة طحن

- مطحنة الكرة 500 قدرة تصنيع الاسمنت

- Ore Processing Flow Chart

- The Best Mobile Mining Equipment

- Ore Black Raymond Mill

- Artifical Sand Making Machine In Germany Sand Making Machine

- How Coal Mill Is Operate

- Companies Mining Diamonds In Marange

- Gold Placer Processing Equipment Exhibition

- Production Line Chalk From Gypsum

- Financial Impacts On The Sand Belt

- Centrifugal Grinder Crushers

- Used Jaw Crushers Seoul Korea

- Small Supari Grinder With Price

- I Need A Number For Crown Mines Minning Company

- Mills Model Coke Machine

- Used Wood Crusher For Sale In Tamil Nadu