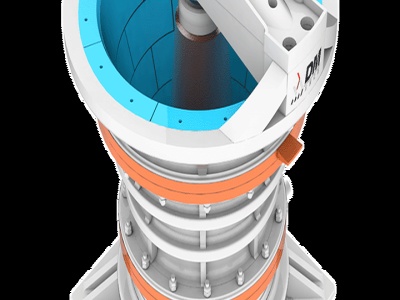

Magnetite Powerder Manufacturing Process

Khetan Group:Magnetite, cenosphere, Silica Ramming Mass

Today, we are one of the eminent manufacturers and exporter of Stainless Steel Pipes, Telescopic Channels (Drawer Slider), Auto Hinges, Stainless Steel Telescopic Channel, Soft Close Telescopic Channel Silica Ramming Mass, Cenospheres, Magnetite Powder, Tundish Board and Quartz Powder. These products are processed using the finest quality ingredients and advanced machinery, resulting .

Process Validation of Ceftriaxone and Sulbactam Dry Powder ...

As the manufacturing process of dry powder injection is mainly dependent on blending process. In the present investigation, blending process was validated at different speeds of blender and the % assay was estimated by HPLC method. The octagonal blender was operated at 13, 17 and 20 rpm samples were taken from 10 different loions inside the blender. At 13 rpm there is much variation in ...

Magnetite Iron Ore Powder at Rs 12/kilogram | Iron Ore ...

We are manufacturer, exporter and supplier of Black Iron Oxide, Yellow Iron Oxide, Ferric Oxide Powder, Grey Iron Oxide Powder, Red Iron Oxide Powder, Iron Ore Lumps and Iron Ore Fines. Giving strong emphasis to scientific innovation from time and again, we have been able to earn a reputed place in the market. All these aforesaid products are tested on various quality parameters of moisture ...

Processing Methods for Reaching Full Density Powder ...

alloyed tool steel powder type 100Cr6 when processed to reach almost full density of about % relative density. The additive manufacturing approach includ the assessment of material fabried by means of es electron beam melting (EBM), involving both solid and shell samples from Ti 6Al4V powder. The studies showed that either samples were printed solid or as shells filled with powder ...

Powder metal manufacturing process | AMES Group Sintering

Powder metal manufacturing process is a technique consists of compacting a mixture of metal powders in a tool or mold that has the negative shape of the part, and sintering the compacted preform in an oven at a temperature lower than the melting point of the base metal.

Metal powders for AM: Manufacturing processes and properties

The major manufacturing processes for AM powders are Gas Atomisation, Induction Melted Bar Atomisation (EIGA), Plasma Atomised Wire (PAW) (Fig. 1) and Plasma Rotating Electrode Atomisation (PREP). There are, of course, many other methods for the manufacture of metal powders. Additional powder production routes which can be used for selected AM processes include water atomisation, .

A New Approach for a Flexible Powder Production for ...

Aluminum powder production for additive manufacturing The possibilities to produce function integrated parts and one piece solutions instead of assemblies, are due to the layer wise build up of the additive manufacturing process. A laser beam melts up a thin powder layer on a building platform. This powder layer is usually 20 to 60 μm thick, in dependence of the required part qua lity and the ...

Characterization of Metal Powders Used for Additive ...

Unlike traditional manufacturing processes such as turning and milling that produce parts by removing unwanted material from a larger piece, additive manufacturing (AM) processes build parts one thin layer at a time. This can be done in a variety of ways, such as melting or sintering of powder via laser or electron beams, extrusion and deposition of polymer via a heated orifice, or selective ...

Titanium Powder | AmeriTi Manufacturing Company

Titanium powder has long been used as an alloying additive for a variety of appliions. Recently, technological advances in the production and use of titanium powder have opened doors into many fields including powder metallurgy, thermal spray, laser cladding, metal injection molding, and additive manufacturing.

What is Powder Bed Fusion? Process Definition and ...

Powder bed fusion (PBF) is an additive manufacturing process and works on the same basic principle in that parts are formed through adding material rather than subtracting it through conventional forming operations such as milling. The PBF process begins with the creation of a 3D CAD model, which is numerically 'sliced' into several discrete layers.

Polymer manufacturing processes

Polymer manufacturing processes can be divided into continuous processes and batch processes. In continuous process where raw material is fed in continuously and the product flow appears continuously extrusion, there is more efficient use of energy and it is easier to maintain a consistent quality. For batch or cyclic processes, such as moulding processes, there is a higher probability of ...

How laundry detergent is made

The Manufacturing Process Although there are three ways of manufacturing dry laundry detergent, only two are commonly used today. In the blender process favored by smaller companies, the ingredients are mixed in large vats before being packaged. The machines used are very large: a common blender holds 4,000 pounds (1,816 kilograms) of mixed material, but the blenders can accommodate .

GRAPHITE MANUFACTURING PROCESS

GRAPHITE MANUFACTURING PROCESS The process of synthetic graphite. manufacturing consists of the following principal stages: Powder preparation Shape forming Baking Graphitization Pyrolytic graphite. Powder preparation . Raw materials for synthetic graphite fabriion (petroleum coke, pitch coke, carbon black, natural graphite and secondary graphite scrap are loaded and stored in raw .

Manufacturing Process

Manufacturing Process. COMPOSITION OF POWDERS. Powder coatings are organic coatings composed of dry, solid (doesn't contain solvents). The base formula of powders is composed of different materials : resin, hardener, filler, pigment and additives. Resin. For powder coatings nowadays two types of resins are used : thermoplastics or thermosettings. Thermoplastic powders. These powders ( ...

Custom Powder Manufacturing

Powder Manufacturing Process Variations. Powder supplements are continually being optimized to support more facets of health and different activities. While there are numerous ways to blend a powder formula, you may find one that is the perfect match for your product. The process generally starts the same for all types of powders, with a measured level of ingredients and correct proportions ...

Powder Metallurgy For Manufacturing

Powder chemistry is a major factor in manufacturing process design. Individual particles must be examined. Metal powders can be a pure element, a mixture of different elemental particles, or the particles themselves can be an alloy material, called prealloyed. Powder metallurgy is unique in its ability to alloy or combine materials that otherwise could not be produced by any other method ...

Tailoring of magnetite powder properties for enhanced ...

· The magnetite powder (sample 4) ... The purity and crystalline structure of powders synthesized under various process conditions (PEG 400 or 20,000, and different PEG/water volume ratios), were determined by powder Xray diffraction, as shown in Fig. 1. The positions and relative intensities of all diffraction peaks collected for samples 1–4 match well those from the JCPDS (Joint .

METHOD OF MANUFACTURING A MAGNETITECOATED IRON POWDER ...

· A method of manufacturing a magnetitecoated iron powder includes putting an iron powder into a reaction liquid containing iron pentacarbonyl and heating the same in an oxidizing atmosphere, or includes heating a reaction liquid containing iron pentacarbonyl in a reducing atmosphere thereby precipitating iron particles and heating the reaction liquid in which iron particles are .

Titanium Powder | AmeriTi Manufacturing Company

Titanium powder has long been used as an alloying additive for a variety of appliions. Recently, technological advances in the production and use of titanium powder have opened doors into many fields including powder metallurgy, thermal spray, laser cladding, metal injection molding, and .

Complete Technology Book on Detergents with Formulations ...

CLEANING POWDER Manufacturing Process Formulations Plant Economics Plant Machinery Fixed Capital Raw Material Total working capital/Month Total capital investment Turn over/annum DETERGENT CAKE AND POWDER Detergent Cake Formula and its Manufacture Formulation Ingredients Manufacturing Process Starting Materials for Organic Compound Basis 230 Per Day .

(PDF) Powder Metallurgy Processes and Making Metal Powder

Powder metallurgy is a production method applied by using powder metal in today's developing industry, which has undergone many processes. Powder metallurgy, which .

Magnetite Ore Manufacture

Magnetite increases the density of most mixtures in which it is present. This property allows magnetite to be used in the manufacture of heavy concrete water filtration coal mining landscaping and production of certain ironbased chemicals. When magnetite is added to a concrete mix it produces. Learn More

Powder Manufacture

Powder Manufacture. There are many ways in which metals may be produced in powder form: comminution of solid metal. precipitation from solution of a salt. thermal decomposition of a chemical compound. reduction of a compound, usually the oxide, in the solid state. electrodeposition.

USA

Process for the conversion of at least the surface layer of an iron article into magnetite and thus prepared articles Download PDF Info ... magnetite layer piece iron coherent Prior art date Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed ...

Latest Posts

- إجمالي التكاليف في شركات تعدين الذهب

- سعر معدات محجر الصخور في موريتانيا

- بيع كسارات الصخور الصغيرة شهادة bv

- صور معدات المعادن الصلبة

- مورد أجزاء الكسارة في مصر

- أفضل مطحنة التلك

- إنتاج الرمل في المحجر

- الجبل الصخري كسارة الصخور الذهبية

- مصنع مطحنة المطرقة في العراق

- سحق المحمول المتكاملة

- كسارة الذهب المختبر مصر الصغيرة

- مطحنة ريمون في عمان

- تحطم الحجر مصر

- تستخدم كسارة الفك الأولية

- أكبر كسارة فكية على الإطلاق

- Titanium Ore Crushing Batu

- Belt Grinding Patent

- Mill Quarrying And The

- Ore Dressing Small Scale Gold Elution Plant

- Pyrolusite Suspension Roller Grinding Machine

- Ore Flotation Laboratories For Graphite

- Gold Washing Machines In Ontario

- Fabriion Of Sand Collecting Vehicle Grinding Mill China

- Construction Block Crane Machine

- Angola Granite Price From Portugal Quarry Equipment For Sale

- Mining Machinery Henan

- Usa Made Hammer Mills For Processing

- Crushing Equipment And Grinding Machine In The Uae

- Malaysia Iron Ore Mines

- L Iron Ore Con Crusher