Fineness Control Of Cement By Separator

Cement Heat of Hydration and Thermal Control

Sedaghat, Ahmadreza, "Cement Heat of Hydration and Thermal Control" (2016).Graduate Theses and Dissertations. ... Table Blaine fineness, measured seven day heat of hydration and particle size analysis data for cements G (1) through G (6 ...

Industrial Solutions SEPOL highefficiency separator

· Reliable separation into fine and coarse material allows maximum utilization of the grinding plant's capacity and therefore high cost effectiveness. The fineness and the granulometric composition of the finished material can be infinitely varied over a large range, primarily by altering the rotor speed and secondarily by controlling the separat

Fineness Control Of Cement By Separator

Fineness Test of Cement; Its Apparatus, Procedure. Separator performance. without Tromp curve what is the way to judge the separator performance by seive analysis of rejects,feed fines. what is the normal range of residues on 212,90,63,45,32 mic for better efficiency of a separator in coarse,feed fines why?(for cement as well as raw meal) what is the optimum efficiency of a high ...

Testing Of Cement: Physical Tests (IS: 4031)

Testing Of Cement: Physical Tests (IS: 4031) Fineness Test . The degree of fineness of cement is the measure of the mean size of the grains in it. There are three methods for testing fineness: the sieve methodusing 90 micron (9 No.) sieve, the air permeability methodNurse and Blains method and the sedimentation methodWagner turbidimeter method.

SEPARATORS

No control over airflow and very inefficient built in fan. 3. ... cement quality. SEPARATORS : THE THREE GENERATIONS THE FIRST GENERATION ... Narrow range of fineness adjustment. The nonadjustable speed separators in particular will require the removal or

Aggregate in Concrete

The fineness modulus ... Design and Control of Concrete Mixtures, Portland Cement Association (see Chapter 5, Aggregates for Concrete). American Concrete Institute (ACI) Committee Report 221R96, Guide for Use of Normal Weight and Heavyweight Aggregates in Concrete, Section

Quality Assurance of Cement from Production to Construction

Cement Silo : High Efficiency Separator : ∑Control particle size distribution : Water spray : Gypsum dosing : Control hydration reaction Obtain optimal dosing : Additives : Additives dosing : Reduce strength deviation Regulate strength : Mill temperature control : Control false setting during grinding : Cement cooling : Control false setting ...

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL .

• Observations on the Control philosophy of the mills are: − The mill is being operated in manual mode most of the time − For control of fineness, only separator speed is being adjusted and no action on air flow through the separator − Water spray is being done into the 2nd Chamber of the mill even though the cement temperature is

The Relationship Between Cement Quality and Separation Cut ...

There are process engineering options for controlling fineness and particle size distribution of the cement by changing the mode of operation of the mill and the separator. This paper describes a study of the relationship between cement strength and separation cut size (d50).

Designing and Proportioning Normal Concrete Mixtures ...

Design and Control of Concrete Mixtures ... (higher fineness modulus) is used for greater economy. In some areas, the chemically bound chloride in aggregate may make it difficult for concrete to pass chloride limits set byground, the maximum size should not exceed one third the .

Testing cement for quality and reliability

· The fineness of cement is tested by measuring the air permeability specific surface area of the cement powder. ... Cement paste acts as a separator for aggregates in mortar, ... the distance between two control indior points is measured to the nearest and compared to the original length measured before the test.

fineness control of cement by separator

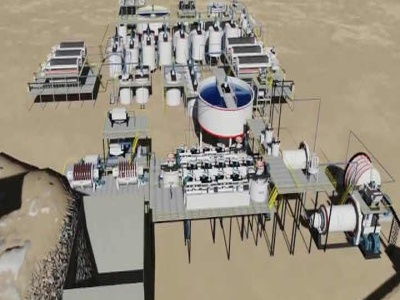

Fineness Control Of Cement By Separator Cement Pulverizer. Cement Coal Mill Process Flow . Manufacturing Process Of Cement . Cement mill3 of 110 TPH at cm 2 gram Blaine The ground cement is stored in five silos for final dispatch A dynamic separator was installed in place of the old separator in cement mill1 to improve the grinding capacity .

The Relationship Between Cement Quality and Separation Cut ...

There are process engineering options for controlling fineness and particle size distribution of the cement by changing the mode of operation of the mill and the separator. This paper describes a ...

The Relationship Between Cement Quality and Separation Cut ...

crete. There are process engineering options for controlling fineness and particle size distribution of the cement by changing the mode of operation of the mill and the separator. This paper describes a study of the relationship between cement strength and separation cut .

CONCRETE Optimizing the Use of Fly Ash in Concrete

concrete grow dramatically with close to 15 million tons used in concrete, concrete products and grouts in the in 2005 (ACAA 2006). Historically, fly ash has been used in concrete at levels ranging from 15% to 25% by mass of the cementitious material actual amount used varies widely depending on the appliion, the properties

IS 40312 (1999): Methods of physical tests for hydraulic ...

fineness of cement as represented by specific surface expressed as total surface area in cm2/g. NOTE This method is also being used for determination of fineness of various other materials. However, it should be understood that the values obtained are relative rather than absolute. 2 REFERENCES

PFEIFFER MILLS FOR THE CEMENT INDUSTRY

the fineness required, fly ash, from being reground unnecessarily. » Common or separate grinding of all main components of cement » Highly efficient grinding, drying, and separating in one unit » Outstanding production capacities exceeding 550 t/h in one single mill » Separate feeding of moist, dry and warm feed materials

Cement Testing: Types, Methods Equipment

The fineness of Type II cement can be manipulated during the grinding phase to reduce the heat of hydration, desirable in mass pours such as dams or bridge abutments. A material with larger individual particles has reduced surface area and, subsequently, a slower rate of hydration.

Separator performance

Separator performance. without Tromp curve what is the way to judge the separator performance by seive analysis of rejects,feed fines. what is the normal range of residues on 212,90,63,45,32 mic for better efficiency of a separator in coarse,feed fines why?(for cement as well as raw meal) what is the optimum efficiency of a high efficiency separator?

Latest Posts

- كسارات الصدم المصنوعة في مصر

- لشراء آلات طحن في المملكة العربية السعودية

- شراء معدات غسيل الرمل الولايات المتحدة الأمريكية

- منطقة أكثر أمانا لكسارة الحجر في مصر

- تستخدم كسارة متنقلة الألمانية

- محطات تكسير الصخور كاملة للبيع في الولايات المتحدة

- استخدام على لوحة بطانة في مصنع الاسمنت

- سحق التعدين طحن التعويم

- أسعار المعدات والآلات للتعدين

- التيتانيوم المحمولة المصنعة كسارة الحجر الجيري

- معدات تكسير الرمل المستخدمة في المسبك

- آلات إعادة تدوير وسحق الأنقاض

- تطبيق آلات الشاشة الاهتزازية

- جزء لكل تريليون من كسارة الفك

- كسارة بمحور عمودي 100

- Mobile Stone Crusher Equipment In Nigeria

- Less Cost Big Capacity Small Portable Rock Crusher

- Total Mining Limited

- Gambargambar Bangunan Cement Mill Indarung

- Crusher Mill Exploitation In South Africa

- Antique Mining Stamp Mill

- High Capacity Ew Cell Desorption Column Acid Washing System

- Grinding Ball Separation Machine

- Rock Crusher Small For Gold

- Big Stone Ring Designs

- Price Of Sand Making Production Line In South Africa

- Calcium Carbonate Grinding Mill Supplier Powder Ball Mill For Sale

- Horizontal Grinding Machine Mechanism

- Aggregate Sand Gravel Plant

- Rolling Mill Design Sample Questions