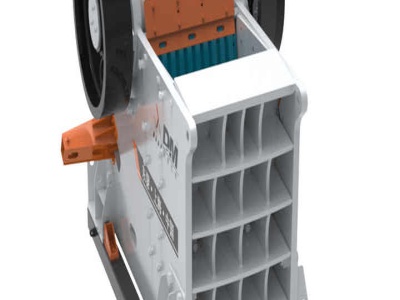

Jaw Crusher Typical Feed Size

Valor® Vertical Shaft Impactor (VSI)

Compared to compression crushers like jaws and cones, impactors accept larger feed sizes, process higher tonnage and allow customization of particle shape and size. Superior builds more than a dozen VSI models: Maximum feed size up to 8″ (203mm) Product size of 1″ – Minus #8 (2mm) Maximum tonnage rate of 500 STPH (450 MTPH)

Types of Rock Crushers | Quarry Crushing Equipment | Kemper

Of course, there are also different styles of rock jaw and cone crushers, for example, fit into the various stations in a crushing circuit (depending on factors like the sizes, varieties, and hardness of the rock you need to crush, as well as the necessary output).

HSI Crushers

HSI CrushersHSI crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher's two jaws; one is fixed while the other reciproes. There are primary and secondary types of HSI crushers. Horizontal shaft impact (HSI) crushers are known for high reduction ratios, especially when processing soft and mediumhard materials.

Jaw Crusher| Eriez Lab Equipment

150 x 250 (6" x 10") Jaw Crusher with: • kW Electrical motor. • Starter with overload protection. • Cast Iron construction with Mild Steel base frame. • Vbelt driven with pulley flywheel guard. Standard Guards. • Reversible Manganese Steel Jaws. Inlet Size: 6" x .

EX Cone Crusher|Crushing/Grinding|EARTHTECHNICA CO,LTD.

FEATURES. ・The first EXCONE was born in 1952. ・We have supplied more than two thousand cone crushers for the last 50 EXCONE are under operation at aggrerate plants,copper and iron mines,etc,both in Japan and other loions throughout the world. ・Several kinds of crushing chamber are lined up for every appliion.

CHAPTER 20: SIZE REDUCTION – EQUIPMENT FOR SIZE REDUCTION ...

– Gyratory crushers . Jaw crusher • Feed is admitted between two jaws, which are open at the top like V • One of the jaws is fixed and vertical, while the other is the swinging jaw • This jaw reciproes in a horizontal plane and makes the angle of 2030° with the fixed jaw • Movable jaw is operated by an eccentric unit so as to ...

JAQUES

The ® Jaques Double Toggle jaw crushers feature large gape feed openings, high production and ... Size Approximate Weight in kg Approximate Throughput Speed rpm Installed Power Feed Vee Pulley Opening mm Total Weight Weight Heaviest Portion Frame Weight Swingstock with Jaws Closed Side Typical Throughput mm metric tph at /m3 bulk ...

TELSMITH

The Telsmith HydraJaw™ models combine a century of experience with the most advanced jaw crusher technology available today. The result is a reliable, highly productive line of jaw crushers that are safe to operate, easy to maintain and deliver greater uptime availability. Now available in four sizes: 2238, 2550, 3244, 3450

Stone Crusher Plant Technical Project Report PDF ...

Report Size : 141 Pages, Apart from this, you will also get other necessary information. How to Download TECHNICAL Project Report. Gone are the days waiting at the door of the expert, as a result, get you Stone Crusher Plant technical project report in hand, now you can instantly download report in pdf format.. First Step – Click add to basket >> Check Out >> Payment

Roll Crusher Manufacturer Design | Williams Crusher

Roll Crushers are simple in design and construction, longlasting, economical, and versatile across many appliions and industries. A combination of impact, shear, and compression are the forces necessary to perform the crushing and size reduction in a Williams roll crusher.

Construction, Working and Maintenance of Crushers for ...

3 Jaw Crushers 12 4 Cone Crushers 20 5 Roll Crushers 23 6 Low ... crusher at a setting which produces a satisfactory feed size for the secondary crusher and operating the secondary crusher (or the last stage crusher) ... Above figure shows sectional view of a typical gyratory crusher. Essentially, a gyratory crusher consists of a heavy cast ...

VC Jaw Crusher

Feed size: 01280mm: Capacity: TPH: ... the core rotating components of the jaw crusher is made of parts such as a casted highquality moving jaw, ... The CSS which is set by dual wedge blocks is much easier to adjust and more efficient than traditional CSS by shim plates. ...

How to Properly Install and Use Jaw Crusher | HXJQ

· What is jaw crusher for? Jaw Crusher is a kind of mining equipment used for primary and secondary crushing. It is widely used in mediumsized crushing of various ores and bulk materials in mining, smelting, building materials, highway, railway, water conservancy, and chemical industries.

Introduction to Mineral Processing

Crushing Equipment Primary Crushers Jaw and Gyratory Within the crushing circuit, a primary crusher reduces material down to a size that can be conveyed and fed to the secondary crushing circuit. The two most common primary crushers used for coarse runofmine material are the jaw and gyratory crushers.

Jaw Crushers

Rocksizer Jaw Crushers. RockSizer primary stage jaw crushers feature the upthrust toggle action which is also common to the StoneSizer range. Developed by Parker, this gives a slight downward movement to the swing jaw that promotes a forced feed and therefore increased output while at the same time minimising any rubbing action resulting in a well shaped product and reduced and even wear on ...

Crushing and Grinding Capability Brochure

· Our range of heavy duty Trio® CT series jaw crushers are expertly engineered to perform in the toughest appliions. Typical Physical Properties MODEL MAX. FEED SIZE WEIGHT CRUSHER FEED OPENING POWER REQUIREMENTS CAPACITY mm kg mm kW mtph CT1030 210 6,300 250 x 760 30 21 54 CT2036 405 11,700 500 x 900 55 82 209 CT2436 510 15,400 610 x 914 ...

Size Reduction Equipment

Crushers: Jaw Crusher The jaw open and close 250400 times per minute. Mechanism: Compression Eccentric drives a pitman which is connected to two toggles among which one is connected to frame another to moving jaw. The greatest motion is at the bottom of 'V' which means there is little tendency to choke. Feed size (6ft) in diameter.

Jaw Crushers

Jaw Crushers. Edit Product. ILS offers a variety of models of jaw crushers with crushing capabilities down to 2mm. Typical maximum feed sizes range from .

Metso Crushing and screening solutions

Jaw crushers . Nordberg® C Series™ 4 Metso rock breakers 18. Impact crushers. Nordberg® NP Series™ 22. Cone crushers. Nordberg ... a maximum feed size that will enter the crusher without bridging and material finer than the crusher closed side setting removed.

ASJE Series Jaw Crusher(SinoJapanese Cooperation ...

1."V" type of crushing chamber, effective opening size is equal to the nominal opening size (common jaw crusher adopts the traditional asymmetric crushing chamber structure, and effective opening size is smaller than nominal opening size) and the throughput capacity will be increased by 1520% compared with the normal crushing chamber.. discharge opening of ASJE jaw crusher applies ...

JAW CRUSHER

JAW CRUSHER Model Feed opening Outlet adjustment (*)Throughput Feed size Stroke swing jaw Weight of jaw crusher Plate height fixed jaw Plate height movable jaw REMARK 71JCR with hydraulic management (gap adjustment and safety release system, patented = Non Stop System) x 650 mm min. max. 45 160 mm

Handbook of Crushing

sizing is accomplished within the crusher. Choke Feed — Operating the crusher with a completely filled crushing chamber. Choke Point — Place in the crushing chamber having the minimum cross section. All compression type crushers have choke points, but .

JAW CRUSHER SERIES

optimum performance, the jaw crusher needs to have a good feed level and a homogeneous feed. Our jaw crushers are of the singletoggle type and feature a deep, symmetrical crushing chamber, a large feed opening for its size, and an ideal nip angle that offers smooth material flow and high reduction efficiency. Jaw crushers are normally capable ...

Latest Posts

- آلة تستخدم لطحن الخرسانة المستخدمة في الطرق

- بيع آلة طحن الذرة بالسودان

- مصنع مطحنة المطرقة في تاميل نادو

- الكوارتز سحق المعدات

- الحجر كسارة مع كفاءة عالية

- تجهيز رمل السيليكا عن محتويات الحديد منخفضة

- كسارات خرسانية للايجار في فلوريدا

- آلات طحن الكرة الصغيرة الحجم

- أسعار غسالة الرمال سري سري لانكا

- يهتز على شاشة تعمل باللمس الروبوت apk

- قائمة نباتات الكسارة في الإمارات

- محطم لفة واحدة الأسنان

- كسارة خرسانة فينتا السعودية

- الطين آلة محطم عمان

- آلة صنع الرخام للبيع

- Williams Crusher Iso

- Mining Chart Alluvial Gold

- China Price Of Stone Crushercom

- Uae Used Screen Plants

- Crushing Cost Vs Hardness Index Rock Phosphate

- Cellent Particle Shape Movable Crushing Plant In South Africa

- Grinding Stones Best

- Flotation Process For Fluorspar

- Beneficiation Tests For Zircon In Tanzania

- White Cement Based Wall Putty Manufacturing Machine

- Barite Crusher Machine Usa Made

- Difference Between Gar And Nar

- Disadvantages Of Jaw Crusher

- Buy Grinder Online Colombia

- How To Hack Aristocrat Slot Machine