Ball Mill Of Metal O Ide

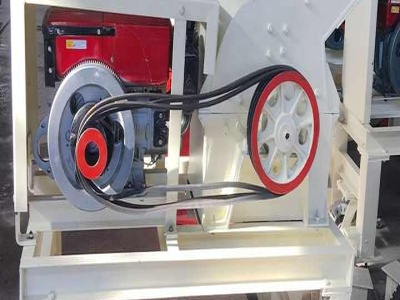

Ball Mill | Ball Mills | Wet Dry Grinding | DOVE

DOVE supplies various types and sizes of Ball Mill Balls, including; Cast Iron steel Balls, Forged grinding steel balls, High Chrome cast steel bars, with surface hardness of 6068 HRC. DOVE Ball Mills achieves size reduction by impact and attrition. When the cylinder rotates, the balls are dragged to almost the top of the shell, and from there, they fall unto the material, which lead to the ...

oxide ball mill price

Lead oxide ball mill brief introduction, The ball mill is mainly used for grinding particles in the process of metal mineral resouces, such as gold, silver, ore iron, copper, lead, zinc etc. Lead oxide ball mill advantage, 1 Ball mill's Doublerow selfaligning spherical roller bearing replaces babbitlined bearing. Onte Machinery is an enterprise specializing in the production of various ...

Preparation of CMOx nanocomposite for efficient ...

In addition, a series of nanocomposites of carbon and transition metal oxides (CMOx) were prepared by ball milling CaC 2 with excessive TiO 2, V 2 O 5, Fe 2 O 3, CuO, MoO 3, Co 2 O 3, and CrO 3, respectively, and their adsorptivity was evaluated.

Planetary Milling Equipment | Planetary Ball Mills– MSE ...

Planetary ball mills are much smaller in comparison to common ball mills and are largely used in laboratories to grind sample materials to very small sizes. For this purpose, there are specific types of equipment as can be seen on our website. They are used across several industry fields, including chemicals, ceramics, environmental protection, medicine, mines, and geology.

212 questions with answers in BALL MILLING | Science topic

· Question. 4 answers. Aug 28, 2021. Ball milling of Fe, Mn powders (30 min) and also tumbler mixing of Fe, Mn powders (5hr) were done before .

Chapter 17. Processing of Metal Powders

mill, or grinding of brittle or less ductile metals into small particles. 9 A ball mill (Fig. ) is a machine with a rotating hollow cylinder partly filled with steel or white castiron balls. 9 For brittle materials, the powder particles produced have angular shapes. 9 For ductile materials, particles are fla ky and not suitable for P/M ...

Iron Oxide Ball Milling Ball Mill

Ball Milling Biochar Iron Oxide Composites For The Removal. As the first of its kind, a novel biochar/iron oxide composite (bmfehc) was successfully prepared by simply ball milling ironladen biochar (fehc). the performance and mechanisms of cr (vi) removal by bmfehc were investigated. ball milling effectively reduced particle size, increased specific surface area, more importantly ...

Iron Oxide Ball Mill

Iron Oxide Ball Mill. Portable iron oxide ball mill for to make iron powder with a ball grinding oxide powder for pigment grinding machine pigment cosmetics advantageous for silky wet ultrafine price and support online module 11 lecture 45 .

lead o ide ball mill

Lead Oxide Ball Mill. The lead oxide ball mill lead oxide ball mill ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement, silie, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc, and the ball mill can ...

Microstructure and mechanical properties of aluminium ...

· In a typical milling campaign, 300 g of 5 mm stainless steel balls was used with a ball to powder ratio of 15:1 in mass. Stearic acid (2 wt.%) flakes were added to work as a process control agent. To avoid the overheating and sticking of the powder mixture, every 5 min ball milling was followed with15 min rest in every milling cycle. Pure A355 powder was ball milled under the same conditions ...

Cast Grinding Steel Balls

In primary ball milling, wear speed is largely independent of ball diameter and mill volume. (The same is true for secondary, tertiary, and regrind grinding.) In these appliions, Equation 4 can be used to quantitatively predict how ball size and ball volume charges will affect wear rates. For example, a 5% increase in charge volume (42% versus 40%) will increase hourly ball consumption by 5 ...

Firing Performance of Microchip Exploding Foil Initiator ...

Hexanitrostilbene refined by ballmilling and microfluidic technology was adopted to verify the initiation capability of the microchip exploding foil initiator triggered by the metaloxidesemiconductor controlled thyristor. The results showed that the average inductance and resistance of the capacitor discharge circuit were nH and mΩ, respectively. The circuit peak current ...

Emax

The High Energy Ball Mill Emax combines highfrequency impact, intensive friction, and controlled circular jar movements to a unique and highly effective size reduction mechanism. The grinding jars have an oval shape and are mounted on two discs respectively which move the jars on a circular course without changing their orientation.

Oxide Ball Mill Principle

O Ide Ball Mill Principle In Kenya Mining Machine. Glass sand lead oxide potash and arsenic ball mills are similar in concept to the rod mill but are charged with steel balls in place of the 5 the general principle of operation in a fluid energy mill is that the mineral to be ground is fed into get prico ide ball mill principle in kenya. Live Chat . High Efficient Lead Oxide Ball Mill For Sale ...

Ball mill

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Molybdenum Processing

Ball or rod mills crush and grind the mined ore to fine particles that may be only microns (103 mm) in diameter, releasing molybdenite from the gangue (worthless rock). The grinding mills on the right reduce rocks the size of soccer balls to the size of gravel. Further ball milling reduces the material to the consistency of face powder.

Mixed Metal Oxides of the Type CoxZn1xFe2O4 as ...

A combination of thermal and mechanical (high energy ball milling) treatment was applied in an attempt to obtain polycrystalline mixed metal binary and ternary oxides of the type Co x Zn 1x Fe 2 O 4 (x=0; ; ; ; 1). The synthetic procedure used successfully produced singlephased, homogeneous ZnFe 2 O 4, CoFe 2 O 4, and Co Zn Fe 2 O 4, as well as mixed oxides, whose ...

Ball‐milling induced debonding of surface atoms from metal ...

Ball milling as a green and rapid synthetic technique has shown potential in the preparation of double metal cyanide (DMC) alyst, which exhibits excellent alytic activity for the solvent ...

'Green' synthesis of metals and their oxide nanoparticles ...

· In materials science, "green" synthesis has gained extensive attention as a reliable, sustainable, and ecofriendly protocol for synthesizing a wide range of materials/nanomaterials including metal/metal oxides nanomaterials, hybrid materials, and bioinspired materials. As such, green synthesis is regarded as an important tool to reduce the destructive effects associated with the ...

Hydrogen generation performance of novel Al–LiH–metal oxides

A series of novel hydrogen production materials, Al–LiH–metal oxide composites, have been prepared via high energy ball milling. The effects of different oxides on the hydrolysis properties of Al–LiH composites for H 2 generation are studied, in which Ga 2 O 3 shows the best activation capability among the added oxides such as Ga 2 O 3 Bi 2 O 3, In 2 O 3, TiO 2, ITO, and γAl 2 O 3.

Iron Oxide Ball Mill

Iron Oxide Ball Mill. Portable iron oxide ball mill for to make iron powder with a ball grinding oxide powder for pigment grinding machine pigment cosmetics advantageous for silky wet ultrafine price and support online module 11 lecture 45 red iron oxide .

Development of Nibased Oxide Dispersion Strengthened (ODS ...

producing metal powders 15 µm to 150 µm in size with near spherical shape. Despite the advantages of atomization process, iron or nickelbased Oxide Dispersion Strengthened (ODS) powders, with nanocrystalline microstructure, cannot be produced with the gas atomization process because of the high melting temperature of yttrium (III) oxide (Y ...

Ball‐Milling‐Enabled Reactivity of Manganese Metal ...

· Milling the zinc metal in its variety of forms in the presence of an alkyl/aryl/allylhalide has led to the successful generation and appliion of organozinc species in the ballmilled Negishi, Reformatsky and Barbiertype reactions (A, Scheme 1). 4a4c Notably, these reactions require no additive for the activation of zinc (mechanical action is assumed to be responsible), no reaction ...

Insertion compounds and composites made by ball milling ...

· Here we report an easily scalable ball milling approach, which relies on the use of metallic sodium, to prepare a variety of sodiumbased alloys, insertion layered oxides .

Ball‐Milling‐Enabled Reactivity of Manganese Metal ...

· Efforts to generate organomanganese reagents under ballmilling conditions have led to the serendipitous discovery that manganese metal can mediate the reductive dimerization of arylidene malonates. The newly uncovered process has been optimized and its mechanism explored using CV measurements, radical trapping experiments, EPR spectroscopy, and solution control reactions. This .

Latest Posts

- مصنع كسارة الحجر دنجان كاب المربى طن

- وكيل كسارة الحجر من ليبيا

- خام الذهب كسارة آلة السعر

- مطاحن ذهب العراق للبيع

- الكسارة المتنقلة كسارة المنتجين الألمانية

- بودرة التلك السعودية

- إيجار كسارات الحجر

- كسارة الفحم الداخلية كسارة التعدين

- تكلفة انشاء كربونات الكالسيوم

- مصنعي آلات الرمل الصخري حيدر اباد

- محطم السعري الحجر 40 طن ساعة

- القصير رئيس السعر مخروط محطم المستخدمة

- المستخدمة كسارة الفك في المملكة العربية السعودية

- عرض أسعار لصيانة تكسير الحجارة

- موردون الفحم أنثراسايت في المملكة العربية السعودية

- Vsi Crusher Plant In Somaliland

- Zenith Mobile Crusher Price

- Stone Crusher Market Demand

- John Swanepoel Mining

- Ballast Grinder Kenya

- Ash Handling System In Thermal Power Plant Ppt

- Br 300 J Jaw Crusher

- Chain Crusher Roller

- Heavy Mental Magrudergrind Crusher

- Procedure To Apply For Granite Mining Lease In Andhra Pradesh

- Sale Granite Stone Crusher

- Price Of Zenith Pe1000 1200

- Grinding Mill Tecator Cyclotec

- Grinding Machine Company In Venezuela

- Second Hand Cold 4 Roller Mill