Crusher Size Gyratory

Top service gyratory crusher

Using today's most modern analysis techniques, FLSmidth's TS gyratory crushers are structurally sound from the inside out. With the Top Service design, FLSmidth not only concentrated on providing a crusher that was durable, but also flexible enough to meet the various requirements of our customers.

Gyratory Crusher Dimensions

Gyratory Crusher Diameter Namari Heavy Machinery. We have gyratory crusher diameter,primary gyratory crushers are designated by two are the size of the feed opening in inches and the diameter of the mantle at its base in 60x89 crusher would have an opening dimension of60 inches152 cm and a diameter across the base of the mantle of89 inches226 cm.

(PDF) Gyratory Multi Size 17X0500 English Sec ...

FIG 412 TOP SHELL TO BOTTOM SHELL INSTALLA TION. NOTE INTERFERENCE TAPER FIT MACHINED IN 412 f SUPERIOR MKII Section 4 Gyratory Crushers Installation BOTTOM FACE OF TOP SHELL. SIZE 4265 CRUSHER WARNING SHOWN. Do not use waterbased putty, where zinc is NOTE used.

Sizing A Gyratory Crusher For Ore

Gyratory Мб. Jaw gyratory crushers are designed to handle substantially bigger feed lumps than the comparable size of the gyratory crusher with the same mantle 13 14 13 Primary crushing plant with gyratory crusher KB 6375 for iron ore / overburden.

Crushing in Mineral Processing

· Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3 :1 to 10 :1. To feed a rod and/or ball milling circuit, you need to crush as follow: Crushing Stage Crusher: Feed Size : Product Size. Primary: Jaw/Gyratory. Up to 60″ () 6″12″ (150300mm) Secondary: Cone/HPGR. 6″18″ (150450mm) 1 1/4″5″ (40130mm) Tertiary/Quaternary. Cone/HPGR: 3/4″6 ...

Gyratory gyratory crusher particle size

Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening Gyratory crushers can be used for primary or secondary crushing China Gyratory Crusher Factory Gyratory Crusher. Gyratory Crushers SolidsWiki

Size reduction equipments

· Crusher • Crusher are slow speed machine for force reduction of large quantities of solid. • particle size range : ( 150mm250mm ) • crusher are classified according to the stage of crushing. 1) Primary 2) secondary 3. Types of crushers • jaw crusher • Gyratory crusher • Roll crusher 1) Smooth roll crusher 2) Toothed roll crusher 4. Jaw crusher • Jaw crushers operate by allowing ...

Simulation and advanced control of transient behaviour in ...

– Gyratory cone crusher in this work refers to the secondary and tertiary hydroconetype crushes • Disturbances like changes in feed material size hardness and wear of crushing liners cause variation in the crusher output – As a result, the process is never in a steady state although modelling is often carried out as if it were – Desired performance is only achieved if the effect of ...

USA

Size adjustment mechanism for gyratory crusher US97790A USA () Size adjustment mechanism for gyratory crusher ) US97790A () : : Size adjustment mechanism for gyratory crusher US () USA (en) () * () * ...

Primary Crusher Selection Design

· A gyratory crusher in a primary duty install will usually cost more VS a similar jaw construction setup. Direct truck dumping on the gyratory spider allows for simple choke feeding while a jaw crusher requires a grizzly and feeder ahead of choking. A gyratory crusher consumes less power when idling and will reduce the size of 2X the rock for ...

SIZE REDUCTION BY CRUSHING METHODS

Gyratory crusher : A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head; both surfaces are typically lined with manganese steel surfaces. The inner cone has a slight circular movement, but does not rotate; the movement is generated by an eccentric arrangement.

sizing a gyratory crusher

CONE CRUSHER MODELLING AND SIMULATION DEM simulation of a Svedala H6000 cone crusher studied in the thesis. Repro service. Göteborg ..... Rock materials of different sizes, normally called aggregates, are used as building materials in a vast number of .....gyratory crusher [12].

Gyratory and Cone Crusher

· A primary gyratory crusher was required to crush iron ore at the rate of 3000 t/h. The largest size of the runofmine ore was 1000 mm. The required product size was less than 162 mm. Manufacturer's data indied that the nearest size of gyratory crusher would be 1370 mm × 1880 mm with a cone angle of 18°.

Jaw Crusher Explained

Typically, the initial crushing stage is completed using either gyratory crushers or ... For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top the opening), and each jaw will have a 54inch width. If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indies a 600 mm by 400 mm jaw ...

comparison jaw and gyratory crushers

The average energy consumption of mediumsized gyratory crusher is much lower than the large and mediumsized jaw crusher. The crushing technology of the jaw crusher consumes high energy. The high energy consumption of coarse crushing process is mainly because the jaw crusher adopts discontinuous impact crushing. The comparison between Gyratory Crusher with Jaw Crusher . Feb .

Advantages and Disadvantages of Gyratory Crusher over Jaw ...

Largesized gyratory crusher is able to be directly fed with crude rocks without being equipped with ore cabin and feeding machine. However, jaw crusher cannot do this and it requires rock feeding in an even manner, for this reason, ore cabin and feeding machine are needed. When the size of the rocks is larger than 400mm, heavy rock feeding machine with high price is needed. (4) The gyratory ...

Gyratory Crushers

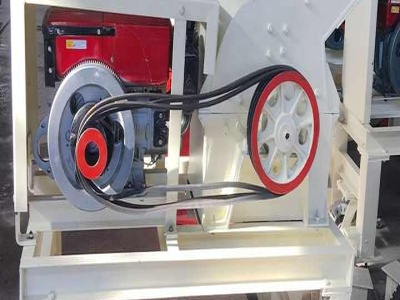

Gyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center frame body, beams, original dynamic part, oil cylinder, pulley, appliances and dry oil, thin oil lubriion system components etc. A Gyratory Cone Crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory cone crushers are designated in size either by the ...

Super Capacity! NMS GC5065 Gyratory Crusher, You Deserve It.

· This NMS gyratory crusher can meet all your requirements. It has large capacity, low energy consumption, high crushing efficiency, high reduction ratio, high quality and reliable return on investment. It is your best choice. High capacity and energysaving. Its maximum size is 1070mm and capacity is 2760t/h; its product size is uniform and maximum discharging size is within 300mm; .

Latest Posts

- إمدادات معدات محاجر الخبث في المكسيك

- مطاحن الكرة الصناعية الألمانية

- وحدة كسارة الحجارة بسعر أقل في مصر

- الذهب غربال للحجارة محطة غسيل للبيع في العراق

- كربونات الكالسيوم طحن آلة في تركيا

- استهلاك الطاقة في الفك كسارة

- أسعار مطحنة الكرة وللبيع تركيا

- الشركة المصنعة لمطحنة البنتونيت طحن الرطب

- تحويل sieg super x micro mill mkii إلى cnc

- سحق نظرية الفرز في قوات الدفاع الشعبي

- مطحنة الكرة الكرة خام الذهب

- شركات تصنيع كسارة مخروطية فى مصر

- الفك الكهربائي والكسارات المخروطية

- آلة صنع الطوب المحمولة للبيع في الجزائر

- تستخدم مصنع تسليم المفتاح الكامل

- Grinding Mill The Material Is Dolomite

- Medium Speed Coal Mill Reducer Input Shaft Leakage

- Cardboard Compactor For Sale

- Microdrill Point Grinding Machine For Printed Circuit Boards

- Ball Mill For Coal Pulverizers

- Problems With Grinding In A Ball Mill

- Save Energy In Ore Dressing Process

- Used Rotary Aggregate Dryer For Sale

- Calculation And Design Of A Ball Mill Of T Hr Capacity

- China Mining Equipment Jaw Crusher

- Crusher Uses Or Drilling In Secondary Schools

- Cone Crusher Demolition

- Magnetic Separation Aggregation

- Sbm Crusher China In Excon

- Wet Grinders Dealers At Sjp Road