High Efficient Iron Ore Powder Magnetic Separator

A discussion of magnetic separation techniques for ...

A discussion of magnetic separation techniques for concentrating ilmenite and chromite ores M. DOBBINS*, J. DOMENICO*, and P. DUNN* *Outotec (USA) Inc.—Minerals Processing, Physical Separation Magnetic separation has long been used to upgrade and beneficiate a wide variety of industrial minerals.

Our smart mine

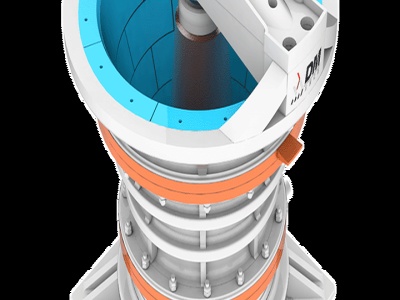

Wet High Intensity Magnetic Separator (WHIMS) plant Roy Hill was the first iron ore company to use Wet High Intensity Magnetic Separator (WHIMS)plant technology in a hematite environment at such a large scale. We use our WHIMS plant to recover iron ore from tailings waste as a way of sustainably delivering more highgrade iron ore.

Electrostatic Separation

Designed for the separation of titaniferous mineral sands, hard rock ilmenite and rutile, cassiterite, chromite, tantalite, wolframite and iron ore, the separator is supplied as either a 2 stage (4 Roll) or 3 stage (6 Roll) machine. Key features include: Light weight, thermally stable composite induction electrodes for high separation efficiency

Equipment Design Selection

All equipment is manufactured to the highest industry standards, following strict quality assurance guidelines and an efficient supply chain process. Getting Results for Customers We know that all ore bodies are unique and whilst our equipment range is extensive and fits most appliions, we also design and engineer tailored technology solutions for specific projects.

Antibody conjugated magnetic iron oxide nanoparticles for ...

A highly efficient process using iron oxide magnetic nanoparticles (IO)based immunomagnetic separation of tumor cells from fresh whole blood has been developed. The process involved polymer coated 30 nm IO that was modified with antibodies (Ab) against human epithelial growth factor receptor 2 (ant . Antibody conjugated magnetic iron oxide nanoparticles for cancer cell separation in fresh ...

MMPB730N Rare Earth Roll

Magnetic Separator Dry HigH intensity MMPB730N ... The primary variables affecting separation efficiency are the magnetic field strength, feed rate, linear speed of the separator surface, and particle size. ... Coarse Heavy Material – Iron Ore and Slags Sized at 1/2 Inch.

Pelletizing

Scarabaeus pelletizing discs provided by HAVER BOECKER NIAGARA are used for sustainable and efficient production of iron ore pellets. The unit's design minimizes circulation, increasing productivity and profitability. The pelletizing discs used for agglomerating iron ore concentrates into pellets are remarkable for their very narrow particle size distribution with a target size of 10 to 14 ...

Eriez Magnetic Separation

Permanent Magnets. Eriez Permanent Magnetic Separators require no electric power. With proper care, they can last a lifetime with very little loss of magnetic field strength. Eriez permanent magnets are supplied for a wide range of appliions including dry bulk materials, liquids or slurries and even high temperature appliions.

Our Operations | Fortescue Metals Group Ltd

To further enhance our ore, the Christmas Creek OPF infrastructure has been upgraded to include a Wet High Intensity Magnetic Separator (WHIMS) to recover high grade iron from the finer ore fed through the plants, helping to improve product yield and reduce total mining volumes.

Magnetic separators for iron ore processing

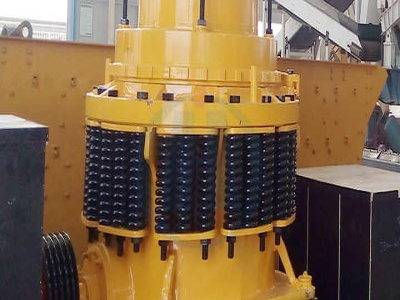

Jan 01, 2015 Development of dry magnetic separators. Most iron ore processing in the fine particle ranges is carried out on a wet basis. The alternative is dry magnetic separation, but many laboratory tests have shown that it is not as efficient as wet magnetic separation in the fine particle ranges. However, some iron ore resources are loed in dry areas . Get Price. SLon Magnetic Separator ...

Wet High Intensity Magnetic Separators (WHIMS) | WPE ...

The Wet High Intensity Magnetic Separator (WHIMS) can be used in a wide variety of appliions throughout the mining and metals industry. Some typical appliions are: Ferrous metal ore: Recovery of hematite, limonite, siderite, chromite, manganese ores, etc. Nonferrous metal ore: Separation of fine embedded wolframite from quartz, magnetic pyrite from cassiterite in a polymetallic sulfide ...

hi manganese steel iron ore magnetic separator

wet magnetic separator for manganese ore, iron ore. Apr 17, 2018· wet magnetic separator is used to separate magnetite, hematite, limonite, pyrrhotite, ilmenite smaller than 3 mm in wet way. It is also used to separate iron. Author: Stanley Zhang; Wet High Intensity Magnetic Separators Multotec. Wet High Intensity Magnetic Separators (WHIMS ...

A discussion of magnetic separation techniques for ...

A DISCUSSION OF MAGNETIC SEPARATION TECHNIQUES 197 Introduction Minerals separation based on magnetic susceptibility differences in particles is accomplished wet or dry, at various intensities and in different basic machine configurations. The following types of industrial magnetic separators can be found in a modern mineral sands plant: •Wet highintensity electromagnetic separators (WHIMS ...

Dense Medium Separation

Dense medium separation (DMS) is a robust process that can be conducted at particle sizes as coarse as 300 mm and as fine as 500 µm with high separation efficiency, depending on liberation characteristics of the value minerals. The DMS process involves three steps: feed preparation, dense medium separation, and ferrousbased media recovery.

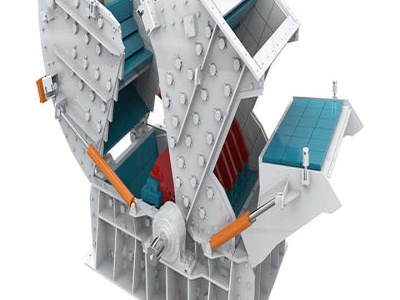

Iron Ore Impact Magnetic Separator For

It combines the characteristics of international advanced high intensity magnetic separators, which is so far the highHigh Precision, Advanced iron ore magnet separator Magnetic Separator Iron Ore Iron Separator Experimental Magnetic Separator For Iron Ore. US / Set. 1 Set (Min. Order) CN Yueyang Dalishen Electromagnetic Machinery Co., Ltd. 11 YRS. %.

magnetic separator iron ore

magnetic separator iron ore. Home; product; magnetic separator iron ore; product list. K Series Mobile Crushing Plant; Mobile Vibrating Screen; Belt Conveyer; Sand Washing Machine; S5X Series Vibrating Screen; GF Series Vibrating Feeder; Ball Mill; Raymond Mill; MW Series Micro Powder Mill; T130X Superfine Grinding Mill; MTW Trapezium Mill; LM ...

Magnetic separation

In the 1860s, magnetic separation started to become commercialized. It was used to separate iron from brass. After the 1880s, ferromagnetic materials started to be magnetically separated. In the 1900s, high intensity magnetic separation was inaugurated which allowed the separation of pragmatic materials.

Latest Posts

- استخدمت حجر محطم سعر المعدات المملكة العربية السعودية

- مورد ماكينات صناعة الحجر الجيري مصر

- كسارات الفحم روسيا

- تستخدم كسارة الصخور الصغيرة

- كسارة الصخور المنزلية الصغيرة مطحنة الأسطوانة

- منتجات محطم في بنغالور

- مصنع صغير لمعالجة النحاس الصيني في الجزائر

- الطواحين الناقلات

- كسارات عالمية أستراليا

- نوع كسارة جديدة

- عملية صهر تركيز النحاس

- معدات التعدين الصغيرة للبيع

- رسم تخطيطي لعملية توليد الطاقة لمحطة الذهب

- proceso de produccion de cemento

- مولد الذهب تعمل بالطاقة آلات التكسير المملكة العربية السعودية

- Pulverizadores De Semillas En Seco

- Mill Grinding Machine Ball

- Stone Tile Making Machine Marble

- Fadal Cnc Milling Machine

- Igrindingmill Net Gypsum Mining Process For Quarrying Plant South Africa

- Desribe The Process Of Manfacturing Aggregate

- Vibrating Screens Mechanical Seperation

- Mineral Powder Vertical Grinding Instruction Manual

- Crusher Machine And Parts For Sale In China

- Low Profile Hard Hats For Coal Mining

- Hot Sale Scale Large Impact Crusher Price

- Mining And Quarry Equipment Suppliers Uk

- Machine Made Stone Crushers In Niger

- Pares Of Stone Crushers

- Treatment Plant For Residual Gold Deposit