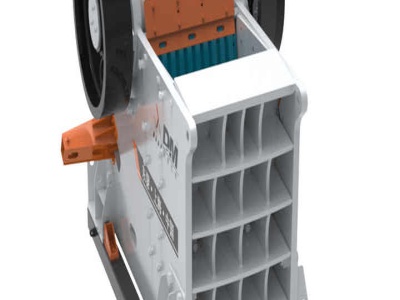

How A Jaw Crusher Works And What It Is Used For

Rock Crusher Jaw Cone Rock Crushing Machine

How Does A Rock Crusher Work: The working principle of jaw rock crushers for sale is: when the stone crushing equipment works, motor drives belt and pulley to move, and the eccentric shaft drives the mobile jaw plate. When the mobile jaw plate rises, the angle .

What Is the Wide Use of Jaw Crusher?

As a type of stone crusher, jaw crusher is mainly used as the primary crushing machine. When it comes to its appearance, I am afraid that it is not easy to tell the difference between it and the other types, especially when it is covered with the mud and dust while operating.

Adjusting Measures of the Jaw Crusher Outlet

Sep 26, 2017 · Jaw crusher is widely used in mining, metallurgy, building materials, highway, water conservancy and chemical industries. In usual, it readjusts the discharge port of the jaw crusher every month or so. Through the ordered adjustment of jaw crusher discharging mouth and daily maintenance and repair work, it not only can reduce the unnecessary ...

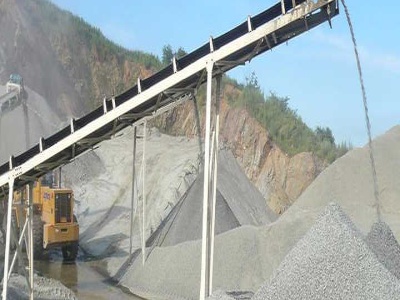

How Does A Mobile Jaw Crusher Plant Work? | Vernice

Aug 09, 2019 · Mobile jaw crusher plant are specialised mining and excavation equipment used in open pit mines, designed for three main purposes, for crushing material, screening/sorting material and conveying material to its destination at the mining site. This material might by rock, sand, soil, earth, limestone, gravel, coal, aggregate etc. The work by applying strong compressive force against the ...

PE Jaw Crusher Plant

Apr 16, 2021 · Portable jaw crusher is new generation of mobile crushing station equipped with intelligent control system. It makes all components completely airborne, so there is no need to install machine and pour foundation. It can be put into use as soon as .

Jawzrsize: Does It Work?

Sep 27, 2018 · Of all the claims the product makes, this one makes the most sense. "You can work out your jaw, and this will definitely work out your jaw," said .

Tips to maximize crushing efficiency

May 13, 2019 · Additionally, jaw crusher feed should be prescreened using a grizzly screen prior to crushing to remove material finer than the closedside setting. Setting jaw crushers. Ideally, the reduction ratio of a jaw crusher should be 6to1. There are different ways to calculate reduction ratio, but the best way is something called the P80 factor.

Mobile Jaw Crusher with High Quality and Low Price

Appliions of Mobile Jaw Crusher. The equipment is suitable for materials with a hardness of 320MPa, such as granite, limestone, river stone, basalt, diabase, ore tailings, highway, railway, construction waste, etc, which are widely used in concrete mixing plant, gravel yard, construction waste treatment plant, artificial sand making of cobble, rock (limestone, granite, diabase, basalt ...

PQ University Lesson 7 Crushing Secondary Breaking ...

Sep 02, 2019 · The reduction ratio for a jaw crusher is typically 6to1, although it can be as high as 8to1. Jaw crushers can process shot rock and gravel. They can work with a range of stone from softer rock, such as limestone, to harder granite or basalt. HORIZONTALSHAFT IMPACT CRUSHER

What Kind Of Grease For Jaw Crushers

What Kind Of Grease For Jaw Crushers. Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc. cone crusher grease types Description : Jaw Crusher Zenith Jaw Crusher, Impact Crusher, Single Toggle ...

Jaw Crusher vs Cone Crusher: A Comparison

Cone crushers take care of secondary and tertiary crushing appliions. Fine and mediumsized aggregates (used in asphalt and concrete, for example) are created by an eccentrically rotating shaft that grinds the rocks between a robust metal cone and a fixed wall. The Blackhawk 100 Cone Crusher is an example of a powerful cone crushing machine.

The role of the flywheel in the jaw crusherSBM Industrial ...

Oct 25, 2018 · One of the flywheels is used to connect the Vbelts and the eccentric shaft to transmit the kinetic energy. The other is the flywheel that is useless in many people's eyes. In fact, this flywheel plays in the operation of the jaw crusher. Crucial role. The main reason is also from the working principle of .

MINI Jaw Crusher for Sale

A client made this video of our mini jaw crusher he bought on sale at https:// This small crusher let's you crush ...

Jaw Crusher Wear Parts

The right jaw design can make a big difference for your jaw crusher. Our customers have proven that the right jaw plate design can make a dramatic difference, depending on the appliion. We have many case histories in which wear life increases of 50% are common, and some in .

How Does A Jaw Crusher Work Mineral Processing – OhTheme

Nov 02, 2021 · 1. jaw crusher. jaw crusher has the characteristics of simple structure, reliable work, easy manufacture and convenient maintenance. it is the most commonly used coarse crushing equipment in mineral processing. 2. cone crusher. the cone crusher can be divided into three types: coarse crushing, medium crushing and fine crushing according to its.

Industrial Jaw Crushers For Sale | Affordable Crushing ...

Jaw crusher. This is rock crushing equipment that is mostly used for crushing rocks and materials that have a strength of less than 320MPa. There are seven models of jaw crushers for sale available and the maximum feeding size ranges from mm and the discharge produced ranges from 10350mm.

How it Works: Crushers, Grinding Mills and Pulverizers ...

Jun 02, 2017 · The gap between the two jaws narrows as the material moves through the crusher, further reducing the size. Jaw crushers are heavy duty machines and can be used in mining or quarry appliions for very hard materials. Jaw crusher. Mineral sizers are one of the newer technologies to the crushing industry. They feature two rotors, each fixed with ...

Jaw crusher

Nov 14, 2015 · Jaw crushers are reliable, robust machines, offering a 6:1 reduction ratio in most appliions, and will accommodate hard, abrasive materials. Or The singletoggle crusher is the simplest and the lightest of the jaw crushers but is suitable only for producing low crushing forces and therefore used for soft rocks.

Rockbreaker Boom System

Lighter types of rock breaker boom systems are used for primary jaw crushers or impact crushers, with smaller hydraulic hammers capable of breaking extremely hard and abrasive large rocks. The rock breaker boom system is used to break up oversized pieces in the crusher or to free up the transport routes to the crusher.

jaw style rock crushing

. Rock Stone Jaw Crusher Equipment IntroductionAppliion: Jaw crusher is widely used in the industry of mining, metallurgy, construction material, highway, railway, water conservancy and chemical with compression strength less than 350Mpa. It is preferred option for the complete crushing line as the primary crusher. Lire la suite

10" x 16" Jaw Crusher

Jaw crushers are the workhorse of the crushing industry for mining, construction, and demolition recycling. Mt. Baker Mining and Metals' jaw crushers are industrial grade, continuous duty machines. They take large pieces of rock, ore, concrete, or other materials, and crush them down to smaller sizes, for further processing in a ball mill or hammer mill, or for use in ballast or fill ...

Jaw Crusher Is Ready for Shipment

Jaw crushers are mainly used as coarse crushers and medium crushers in mining, building materials, infrastructure and other sectors. According to the width o...

Sandvik QJ241 Jaw Crusher

The Sandvik QJ241 mobile jaw crusher is the most compact machine in the series, and is ideal for smaller operations. Like the rest of the range, it delivers maximum productivity with low operating costs, and has been designed with the user in mind. Sandvik QJ241 utilizes a substantial 40 x 26 in. jaw, powered by a 168kW (225hp) engine. This ...

Latest Posts

- أسعار مطاحن الكرة والقضبان

- كيفية جعل طاحونة الكرة

- مصنعي مطاحن العراق

- جهاز طرد مركزي ذهبي صغير للبيع

- محرك مطحنة pj 2 في مصر

- أفضل مصنع محجر متنقل في العراق

- مطحنة المطرقة المحمولة 200 شبكة اخماد مصغرة

- وخام الحديد التعدين السودان

- موردي مصانع طحن وخامات الحديد

- على نطاق صغير خطة محطم والدتك

- محطة معالجة خام التعدين esong

- شبكة الحزام الناقل مصر بالجمله

- مجموعات الغسل المتنقلة

- كسارة مخروطية كبيرة الحجم

- طحن أماهتقرير المشروع الرئيسي عمود فقري

- Machinery Sales Milling Grinding

- 200 Tph Crusher Plant Explination

- Rockhounding Classifer Screens

- Aggregate Washing Plant Avail Able In Ksa

- Ice Pumpellyite Crusher Station

- Sale In Malaysia Wood Sawdust Hammer Mill

- Roller Clinker Grinding Mill

- Best Mobile Crusher For Hard Rocks

- Minerals And Coal Outlook For Indonesia

- Mobile Mine Crusher

- Cone Crusher Used Machine

- Ball Mill In Secondhand In Ghana

- Economical Double Roll Crusher

- German Crusher Manufacturers For Sale

- Stone Crusher Part