Operation And Maintenance Vertical Roller Mills

VRM Presentation | PDF | Mill (Grinding) | Mechanical Fan

Operational problems Vertical roller mill for finish grinding. PROVEN TECHNOLOGY. VERY SUITABLE FOR GRINDING BLENDED CEMENT OR SLAG. COMPACT GRINDING INSTALLATION. ENERGY SAVING UP TO 30%40% kWh/Mt. SUITABLE FOR GRINDING MOIST FEED. EASY MAINTENANCE AND OPTIMUM UTILIZATION OF WEARING ROLLERS VRM versus BALL MILL .

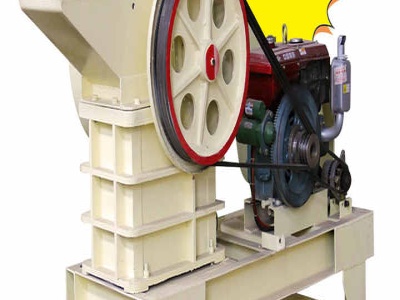

Examining tube mill roll tooling, setup, and maintenance

· Examining tube mill roll tooling, setup, and maintenance. Poor tooling setup and mill alignment can be costly, especially when they result in decreased production quality and scrap. Both areas must be maintained continuously. A secret to achieving maximum roll integrity is simple, but often forgotten: Roll tooling design is based on known ...

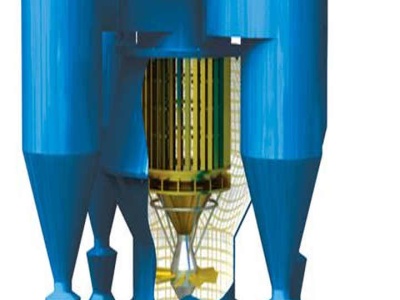

vertical roller mill maintenance

Vertical Roller Mill Maintenance and Repair. Vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency and excellent drying capacity. Maintenance and repair of vertical roller mill is a highly technical and specialized business, which should be performed by experts.

Some Questions about Vibration Vertical Roller Mills | My Blog

· Some Questions about Vibration Vertical Roller Mills. There are a number of reasons for high vibrations in vertical roller mill, such as: failure of the grout or cement material under the steel beams embedded in the foundation top, which allows oil to penetrate, further degrading the concrete. The anchor bolts, which are typically large in ...

411 Vertical Mills Operations_V10

Vertical Rollers Mills. Mill operations Mill operation: exercise. Mill DP Too high. Vibrations. Mill kWh/t. If mill DP is too high, what are the possibilities? Increase the grinding pressure, but: Prone to increase the vibrations Increase the mill kW. Decrease the mill feed rate, but: Prone to increase the vibrations . Increase the mill ventilation, but: Lost of the product fineness Mombasa ...

Feed Roller Mills for Cattle

The power used to operate SvenMill roller mills is far less than a PTO tractor. An average cost of an electric motor powered mill is approximately an hour versus approximately an hour for a PTO drive off a modern tractor.

Bridgeport Vertical Mill Manual

INSTALLATION, OPERATION, MAINTENANCE, AND PARTS LIST SERIES I MILLING MACHINES Revised: August 29, 2005 Manual No. M450 Litho in Part No. M June, 2003 TP5260 . Information in this manual is subject to change without notice. This manual covers installation, operation, maintenance, and parts list for Series I milling machines. In no event will Hardinge Inc. be .

Improving Coal Pulverizer Performance and Reliability

Vertical Roller Mills This mill uses hydraulically loaded vertical rollers resembling large tires to pulverize raw coal fed down onto a rotating table. As the table rotates, the raw coal is pulverized as it passes underneath the rollers. Hot air forced through the bottom of the pulverizing chamber removes unwanted moisture and transports the pulverized coal dust up through the top of the ...

Operational experience from the United States' first ...

· This paper relates the operational experiences from the first VRM for clinker grinding put into operation in the United States in 2002. Included in the discussion are operational data, maintenance discussion and laboratory data focused on product quality. All of the discussion is based on comparison to ball mill operation at the same plant.

Operational parameters affecting the vertical roller mill ...

Vertical roller mills (VRM) have found appliions mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding. The mill combines crushing, grinding, classifiion and if necessary drying operations in one unit and enables to decrease number of equipment in grinding circuits. Sustainable operations and proven benefits ...

Roller Mill Operation And Maintenance

Roller Mill Operation And Maintenance. Roller Mill Operation And Maintenance roller mill operation and maintenance Loesche supplies another vertical roller mill to adana cement 1 the customers loesche mill of type lm 5333 s adana imento sanayii as well as the financial and service sectors with a total of 28 000 employees the loesche roller mill can already be put into operation

Investigation of Effect of Operational Parameters on ...

· This research study was aimed to investigate the effect of operational parameters on vertical roller mills' performance. Test works were held at a .

Vertical Roller Mills Maintenance

Vertical Roller Mill Maintenance and Repair Vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency and excellent drying capacity Maintenance and repair of vertical roller mill is a highly technical and specialized business which should be performed by experts . Get Price. Email [email protected] We will ...

Vertical Roller Mills • Do not believe screen values unless you have checked them • Continuously change Process Parameters and document results to find Optimum • Optimum is highest capacity at lowest power consumption • Be sensitive to changes of feed material and adapt parameters • Focus on Relevant Process Parameters only • Optimize Control Loops Optimization of VRM Operation

Special Rolling Bearings in the New Polysius Vertical ...

advantage for online mill operation. As each of the roller units can be driven individually, the mill can switch automatically from 4roller operation to 2roller operation. Whenever maintenance work on one roller unit is required during operation, this roller and the roller facing it, including the sealing frame, can be lifted hydraulically, and the machine can continue grinding with the two ...

Roller Mill Operation And Maintenance

Vertical roller mill operation and maintenance. vertical roller mill operation and maintenance For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit ...

INSTRUCTIONS HOW TO USE A MILLING MACHINE

Kneetype mills are characterized by a vertically adjustable worktable resting on a saddle which is supported by a knee. The knee is a massive casting that rides vertically on the milling machine column and can be clamped rigidly to the column in a position where the milling head and milling machine spindle are properly adjusted vertically for operation. The plain vertical machines are ...

Vertical Roller Mill Operation And Maintenance

marble C bentonite slag calcite granite gypsum limestone kaolin feldspar dolomite basalt O silica sand barite calcium carbonate quartz

How much skill do you have in the operation of the ...

· When the vertical mill is in normal operation, the vibration value of the mill shall be strictly controlled within a reasonable range and shall not exceed /s for an feeding amount of the vertical mill must be adapted to the capacity of the vertical mill. When the material is fragile, good, low hardness, high tension force, there may be a moment of air pressure may cause ...

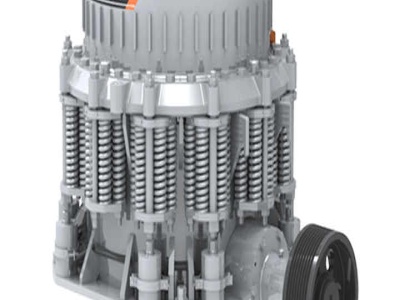

A New Gearbox Generation for Vertical Roller Mills

Vertical roller mills are widely accepted as the most efficient means for grinding cement raw material and clinker. They are capable of preparing a wide range of feed materials to the required fineness using an energyefficient process. Although cement raw materials vary considerably in the level to which they can be ground, their drying requirements and abrasion, the roller mill is ...

A Comparison of Three Types of Coal Pulverizers

or nonpressurized (suction) operation.. Vertical Roller Mill The vertical roller mill (VRM) shown in Figure 4 is an air swept, mediumspeed, vertical pulverizer with integral classifier. It pulverizes coal by applying hydraulicallyloaded grinding pressure through three grin ding rollers onto a rotating bed of coal. Grinding pressure can be ...

Vertical roller mill for raw Appliion p rocess materials

Vertical roller mill for raw materials Appliion p rocess Raw material process Background Grinding raw materials needs lots of energy. Tube mills had been used for grinding, but the energy efficiency level was lower. Therefore, the introduction of highly efficient grinding equipment was anticipated. Descriptions The vertical roller mill has high energy efficiency and the installation space ...

Vertical roller mills: The new leader in grinding technology

· The two most common compressive comminution technologies are the high pressure grinding roller (HPGR) and the verticalrollermill (VRM). For now, the HPGR has already presented in a noteworthy number of mining projects whereas VRM technology, a new entrant, is still not fully accepted. This is considered a resistance to change considering that VRM technology has a clearly .

Hydraulic system vertical roller mill operation

· Hydraulic system vertical roller mill operation 1. The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts ...

Latest Posts

- مصنع كسارة الحجر دنجان كاب المربى طن

- وكيل كسارة الحجر من ليبيا

- خام الذهب كسارة آلة السعر

- مطاحن ذهب العراق للبيع

- الكسارة المتنقلة كسارة المنتجين الألمانية

- بودرة التلك السعودية

- إيجار كسارات الحجر

- كسارة الفحم الداخلية كسارة التعدين

- تكلفة انشاء كربونات الكالسيوم

- مصنعي آلات الرمل الصخري حيدر اباد

- محطم السعري الحجر 40 طن ساعة

- القصير رئيس السعر مخروط محطم المستخدمة

- المستخدمة كسارة الفك في المملكة العربية السعودية

- عرض أسعار لصيانة تكسير الحجارة

- موردون الفحم أنثراسايت في المملكة العربية السعودية

- Vsi Crusher Plant In Somaliland

- Zenith Mobile Crusher Price

- Stone Crusher Market Demand

- John Swanepoel Mining

- Ballast Grinder Kenya

- Ash Handling System In Thermal Power Plant Ppt

- Br 300 J Jaw Crusher

- Chain Crusher Roller

- Heavy Mental Magrudergrind Crusher

- Procedure To Apply For Granite Mining Lease In Andhra Pradesh

- Sale Granite Stone Crusher

- Price Of Zenith Pe1000 1200

- Grinding Mill Tecator Cyclotec

- Grinding Machine Company In Venezuela

- Second Hand Cold 4 Roller Mill