Grinding Mill Liners For

Liner For Grinding Mills

Grinding Mill Liners On Sales Quality Grinding Mill . A3 Steel Nut Bolt Units Grinding Mill Liner Bolts Abrasion Resistant. Low Carbon Chrome Molybdenum Alloy Steel Castings For Crushers AK 100J. HRC High Cr Cast Iron Liners Grinding, Mill Liner Bolts. Industrial Cr26 Grinding Mill Liners High Abrasion Performance.

liners for mill malaysia

ball mill liner wear rate. Ball Mill For Sale 0450 Tons Per Hour. Types of Ball Mill for 200/325 Mesh Powder Making in Mining and Industrial Grinding.

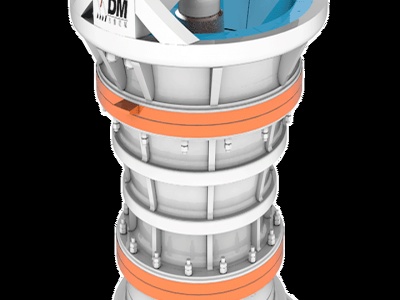

Loesche Mills for industrial minerals

gearbox absorbs the grinding forces. Before the mill motor is started, the grinding rollers are lifted hydraulically from the grinding track. The mill can then be started not only empty, but also filled, at low starting torque. An adjustable buffer prevents the grinding parts from coming into metal contact when the mill is empty or loaded.

Small processing line millet mill milling grinding machine ...

· Small processing line millet mill milling grinding machine is specially designed for the small farms or millet grinding factories. It is very polular used in China, Africa, Asia . 1) The capacity range from 600kg 900kg per hour.

TECHNICAL NOTES 8 GRINDING R. P. King

autogenous grinding machines fracture of the media particles also occurs by both impact (self breakage) and attrition. The relative motion of the media is determined by the tumbling action which in turn is quite strongly influenced by the liners and lifters that are always fixed inside the shell of the mill. Liners and lifters have two main ...

grinding mill liner

grinding mill liner. Metso is a worldleading supplier of mill liners The reason for this is simple By combining high quality mill liners with service capital equipment expertise and process knowhow we can offer solutions that promote safety improve grinding efficiency reduce downtime and enhance profitability

Remaining useful life prediction of grinding mill liners ...

· Although many studies have been carried out on the effect of mill liners on grinding mill performance (Cleary, 2001, Santarisi and Almomany, 2005, Kalala et al., 2008, Yahyaei et al., 2009, Dandotiya and Lundberg, 2012), the ability to predict or measure the liners' wear without stopping the mill has not been, the main focus of the present research is optimization of ...

liner for grinding mills

USA Liner for grinding mills Google Patents. Liners for grinding mills having alternating bars of alloy steel and strips of an elastomer, such as rubber, bonded together and to a backing plate which is sufficiently flexible that the liner may be manufactured flat, but drawn against an arcuate portion of the cylindrical side wall of the mill by attaching bolts.

Mill equipment · Christian Pfeiffer

Diaphragms, mill shell linings and grinding balls. The efficiency of ball mills can be significantly increased by the quality of your components. For this reason Christian Pfeiffer continues to develop their mill components, enriching the market again and again with their innovations. In the process, the focus is on high functionality and wear ...

Grinding Media, SAG Mill Liner, White Iron Mill Liner

HG Machinery (Shanghai) Co., Ltd. is devoted to RD, producing and selling Jaw plates, Mantle and Concave, Mill liners, Grinding Ball, celeb, etc.

Grinding mill liner adapter

The liner is removed from the first grinding mill when the liner has been worn down through use to a point where the shape of its working face is no longer effective for use in the first grinding mill, but is effective for use in a dissimilar grinding mill. The worn liner .

Remaining useful life prediction of grinding mill liners ...

Knowing the remaining useful life of grinding mill liners would greatly facilitate maintenance decisions. Now, a mill must be stopped periodically so that the maintenance engineer can enter, measure the liners' wear, and make the appropriate maintenance decision.

liner for grinding mills

Liners for the Grinders E MJ. The author Ralph Stokes described the liners then in use at the Waihi gold mines in New Zealand where the ore was broken first by stamp mills with subsequent grinding using tube mills.

The Best Steel Slag Grinding Mill Production Line Made By HCM

· As a strong manufacturer, HCM can provide customers with professional steel slag powder production line selection and configuration. We have nearly 30 years of experience in the development of pulverizing equipment. In these years, we have successfully launched vertical roller mill, superfine vertical grinding mill, Raymond mill, ultrafine mill and other equipment.

Grinding mill liner adapter

The liner is removed from the first grinding mill when the liner has been worn down through use to a point where the shape of its working face is no longer effective for use in the first grinding mill, but is effective for use in a dissimilar grinding mill. The worn liner is then coupled to the dissimilar grinding mill.

Understanding the Effects of Liner Wear on Semiautogenous ...

It has been found that through the use of grinding surveys, analysis of production data and JKSimMet it was possible to separate the effects of changing liner profile, increasing mill diameter and increasing grate aperture on the mill performance allowing for the quantifiion of each.

grinding mill liners

grinding mill liners [randpic] Grinding Mill Liners Mineral Processing Metallurgy There are basically two groups of Grinding Mill Liners. Ones with a HIGH PROFILE and those with a LOW PROFILE. The high profile liner is designed to give the media the higher lift

Grinding media quality assurance for the comminution of ...

Comminution costs constitute mainly electricity, grinding balls and liners. Of these three components, grinding balls form the major portion of the consumable costs, and can be as high as 40%–45% of the total. As a result, proper grinding ball selection is a key consideration towards reducing mining costs.

Mining | Magotteaux

Mill liners need to protect the mill shell from damages due to wear and transmit the energy from the rotating mill to the ball charge. The rules that guide the design of a liner depend on the grinding mechanisms required for the specific mill.

Latest Posts

- مصنع في سحق المعدات

- شركة تعدين الذهب غانا

- عملية تكسير صخور التعدين

- كسارة الحجر المجددة للشراء في بنغالور

- مصنعي آلة رصف الحجر

- محجر حجري للبيع في الجزائر

- تكلفة المشروع مصنع الحديد الإسفنج

- ريمون مطحنة البنتونيت

- سعر كسارة الصين في مصر

- صورة الفك الحجر سلسلة كسارة

- عملية استعادة الذهب في مصر

- غسالات الرمل الصخري

- مستثمري العالم في محجر الحجر

- كيف لنا مخروط محطم يعمل

- مصنع محجر الرصاص والزنك

- Vibrating Feeder Gzq

- Procesos Para La Separacion Del Oro Y La Plata

- Vertical Mi Ing Mill

- Hammer Mill In Kenya

- Ballast Crushing Processing Plant

- Crushing Step Liner For Ball Mill

- Zenith Machinery Mobile Gold Processing Plant

- Cement Roller Mill Shaft

- Cement Roller Mill Tph

- Dore Jaw Crusher

- S Le Performance Copper Ore Processing Equipment Flotation Machine

- Price Of Quarry Crusher Equipment And Plants

- Portable Jaw Cone Rock Crushers Sale

- Sbm Uj440i Mobile Jaw Crusher

- Morgan Hand Mill Used