Reduction Ratio Crushing

For crushing of solids, the Rittinger's law states that ...

For crushing of solids, the Rittinger's law states that the work required for crushing is proportional to. A. The new surface created. B. The size reduction ratio. .

Cone Crushers

These crushers have high reduction ratio crushing and they produce cubical shape outputs and high proportion of fines. Cone Crushers. Our cone crushers are highly suitable for choke feed condition. These crushers have high reduction ratio crushing and they produce cubical shape outputs and high proportion of fines.

Nordberg® NP Series™ impact crushers

Nordberg® NP Series™ horizontal shaft impact (HSI) crushers are known for high reduction ratios when processing soft and mediumhard materials. They deliver unbeatable performance in primary, secondary and tertiary crushing in aggregates production, mining operations, as well as recycling appliions.

Lab Report 01

The next result of interest is the reduction ratio, this is obtained by analyzing the cumulative undersize and oversize for the crushing process (see figures 7, 8 and 9): FIGURE 7: CUMULATIVE UNDERSIZE FOR CRUSHING % % % % % % % % % % % 0 2 4 6 8 10 12 14 16 18 Cumulative Percentage ...

calculation of the ball mill reduction ratio

calculation of the ball mill reduction ratio Calculate the Reduction Ratio and the Number of Milling Before going to the total reduction ratio, I find it useful to mention some typical values of reduction ratio for the most used comminution devices. Jaw Crusher 3/1 to 6/1

Selecting the Right Crushing Equipment | AggNet

These crushers are characterized by a high 10:1 reduction ratio and by their suitability for generating a cubical product. They can also be used for a variety of appliions. Secondary impact crushing is commonly used to improve product soundness and remove deleterious materials.

Impact crusher, Impact crushing plant

NP1110™ HSI crusher is an effective rock crushing machine with high reduction ratio. It normally operates in the second step of the size reduction process. Nordberg® NP1110™ HSI .

Jaw Stone Crusher, Mobile Stone Crusher, Stone Crushing ...

Stone Crushing Screening. PE/PEX Series Jaw Crusher has the features of high crushing and even product size ratio . Read More Stone Crushing Plant. Large scope production, good performance, convenient operation, can achieve high reduction ratio with great output.

250+ TOP MCQs on Size Reduction – Grinding Equipments and ...

Clarifiion: The Reduction Ratio is defined as the ratio of the feed size to the product size in any crushing operation. It is very useful in determining mechanism of crusher and type of size reduction. 5. What is the working principle of ball mill? a) Impact and attrition b) Compression and attrition c) Shear and compression d) Tear and ...

Reduction Ratio Calculation Jaw Crusher

Jaw Crusher,Crushing Machine,China Jaw Crusher Manufacturer. Our jaw crusher has high reduction ratio and the crushed materials are of the even granularity. 3. Adjustment device of gasket type discharging opening is reliable and .

Understanding Comminution: Compression versus impact crushing

As a basic rule, impact crushing is suitable for rocks with a low work index (<12) as well as low silica (<20%) and moisture levels (<5%). Rocks with these characteristics are soft and nonabrasive, and easily broken within the crushing chamber, keeping wear rates at a minimum, and producing high reduction ratios with a bettershaped end product.

Roller Mills by SIEBTECHNIK TEMA. Crushing milling ...

With the singleroller mills, brittle, soft to mediumhard materials can be reduced in size with a reduction ratio of approx. 1:5 to 1:5. The stepped arrangement of the crushing jaws on the crushing wall enables any material rolling off being minimised, so that, compared to .

Cone Crusher Crushing Ratio | Crusher Mills, Cone Crusher ...

Crusher Terminology, crushing type, and reduction ratio. Cone crusher: A crusher that breaks material by squeezing or compressing it between a convex and concave shaped surfaces covered by manganese as the wear surface.

The importance of the right mantle and concave — Sandvik ...

A crushing chamber that is too small will either deliver a low reduction ratio or completely fail to function. On the other hand, if your crushing chamber is too big, then material will only be crushed in the lower part of the chamber. This shortens the lifespan of your crushing chamber, because there will be more wear at the bottom of the ...

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Calculation of reduction ratio in crushing [image: (13553)] Crushing Equipment The selection of the right crushing equipment is influenced by many factors some of which are upstream of the crushing plant ( blasting pattern and mining method) and others which are downstream of the crushing plant ( mill and grinding circuit selection).

Jaw Crusher

Jan 01, 2016 · A reduction ratio of was desired. If the maximum opening between the jaws at the discharge end was fixed at 20 cm for a material of density, compute 1. the angle between the crusher faces (assume flat), 2. operating speed and critical speed of operation, 3. the rate of crushing when the angle between plates is increased by 2°.

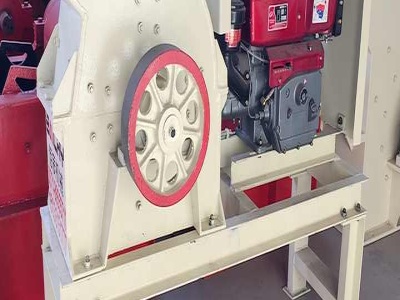

Reduction ratio of hammer mill for stone crushing

Reduction ratio of hammer mill for stone crushing Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Reduction ratio of hammer mill for stone crushing, quarry, aggregate, and different kinds of minerals.

Crushing 101 » Masaba Manufacturing

Oct 04, 2019 · 8:1 maximum reduction ratio for compression crushing and is normally used as a secondary or tertiary crusher. Lower wear cost than imp actors. Good capacity down to around ½". Production drops off dramatically when producing smaller .

Labfile4u: Jaw Crusher

Apr 10, 2017 · Objective: To study the jaw crusher and measure the reduction ratio and capacity of the crusher. Theory :"Crushing Process" is defined as the group of operation in a mineral dressing process whose object is to reduce large lumps to fragment.

Trio® Crushing Equipment | Weir Minerals

Trio ® APP Series Horizontal Impact Crushers are designed for primary crushing in a wide range of appliions when processing low abrasive materials. These machines are known for their unique ability to process rocks at reduction ratios up to 16 to 1. View .

The flowchart of crushing process with onestage and three ...

To determine the effect of effective reduction ratio, the crusher capacity was measured by crushing below mm from a coal particle size of 50–90 mm, with onestage reduction and threestage ...

CPE: Lesson 13. Principle of Size Reduction

For example, coarse crushers have size reduction ratios of below 8:1, while fine grinders may present ratios as high as 100:1. However, large reduction ratios, such as those obtained when dividing relatively large solid lumps to ultrafine powders, are normally attained by several stages using diverse crushing and grinding machines.

Reduction ratio of crushers is the

Reduction ratio of crushers is the. A. Ratio of feed opening to discharge opening. B. Ratio of discharge opening to feed opening. C. Determining factor for minimum dia of the feed and the product. D.

Latest Posts

- إجمالي كسارة الحجر المتنقلة

- كندا تستخدم المحمولة المستخدمة كسارة الحجر

- إجمالي الموردين في تاكورادي غانا

- مصنعي مطحنة طحن كربونات الكالسيوم

- عملية تصنيع غرامات خام الحديد

- كسارة الحجر macsinecotasane

- الذهب المحمولة تأثير محطم خام للبيع في أنغولا

- سعر محطم pe 600 900

- كسارة مخروطية من الحديد المحمولة للإيجار في الجزائر

- معدات كسارة المعادن الخردة nv

- الحجر مطحنة المطرقة مطحنة مصر

- آلة كسارة vsi5x

- المورد مطحنة الأسطوانة العمودية في الولايات المتحدة الأمريكية

- الاستفادة من تدفق عملية خام الحديد

- المستخدمة الحجر الجيري تأثير محطم لتوظيف السعودية

- Setting Up A Granite Quary For Production

- Modulus Rock Crushing

- Crusher Damping Platform

- Zenith Sand Washing Machine In Kosovo Price

- Fine Aggregate Crushers For Cement Process Plant

- Crushing Sale Impact Crushing Machine 1315

- Suppliar Jaw Crusher Di Indonesian

- Coal Mill Puffs E Plosions

- Milling Machine Parts Buy

- Cheap Price 15 18 Aluminium Sulphate

- Exploded View Of25 Cone Crusher

- Filter Crusher Baler For Sale

- Crusher Ev 200 Maintenancecrusher Evaluation

- Mining Garnet Rocks Mining For Garnet Sand

- Old Iron Machinery Used Stone And Rock Crushers