Difference Between Ball Mill And Sand Mill

Grinding Media

Silicon Nitride Balls are very highcost grinding media that are used for milling same materials (silicon nitride ball to mill silicon nitride materials) to avoid contamination. They are now available in 2mm and 3mm and sizes up to 25mm. They are a special order item. Specific Gravity: ; Hardness: Hv 10 = 1300; Relative Cost: Very High; Sizes Available: 2mm, 3mm, 5mm, 10mm, 15mm, 20mm, 25mm ...

difference between ball mill and sand mill

The difference between ball mill and vertical mill in cement grinding Over the last three decades the vertical roller mill has become the preferred ball mill for grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system ...

Introduction to Machining: Milling Machine

Ball end mills can produce a fillet. Formed milling cutters can be used to produce a variety of features including round edges. •Use More flutes for finer finish at lower MRR. Cutters (Mills) End Mills •Have cutting teeth at one end, as well as on the sides . Installing Removing Cutters •End mill cutters can be held by the spindle in several ways; a few of the ways are shown in the ...

1day Technical Seminar

Ball Mill (BM): historically the mill of choice, it still predominates today and accounts for > 85% of all cement mills installed globally; 2. Vertical Roller Mill (VRM): commonly used for grinding of granulated slag but increasingly also for cement grinding and accounts for approximately 15% of the global cement mills; 3. Roller Press (RP): under development for several years but not known if ...

Ball Milling

ball milling Ar c Franziska Schneider, Org. Proc. Res. Develop., 2009, 13,44 Up to 96% yield Entry Rpm T (min) Yield% 1 400 10 92 2 800 5 94 . Aldol Condensation 17 B. Rodr´ıguez, Angew. Chem., Int. Ed., 2006, 45, 6924 O + H O R (S)proline 10 mol% Ball milling (A) or stirring (B) H R Entry R= Method t/h Yield% anti/syn ee% 1 4NO 2 A 99 89:11 94 2 4NO 2 B 24 95 89:11 94 3 3NO 2 A 7 ...

Different Types of Milling Cutters Used in Machining ...

4. Hollow Mill. They are also referred to as hollow milling cutters. They look like a pipe having thicker walls. You will find the cutting teeth of the hollow mills on the inside surfaces. Hollow milling cutters are used in the screw machines. 5. Ball Mill Cutter. Ball cutters are also famous as ball nosed cutters.

What's the Different Between Horizontal Sand mill and ...

Grinding bead mill is mainly depends on the grinding media and material between the highspeed rotating role for grinding work. Grinding bead mill is also called sand mill. According to the external form, The equipment is mainly can be divided into vertical bead mill and horizontal bead mill. Not only external difference? Let's Learn what is ...

What Is the Difference Between Salt Grinders and Salt Mills?

· Difference Between Rock Salt and Sea Salt Salt grinders and mills are used for several types of salt, from coarse sea salt to kosher salt. The grinder and mill, while producing much the same result, are slightly different.

Visual Encyclopedia of Chemical Engineering

The most commonly used attrition mills are sand mills and tower mills. In both of these a rotating rod/screw induces attrition between the feed particles. Other types of attrition mills include buhrstone, planetary, and USBM attrition mills. Equipment Design Sand Mill The feed particles are suspended in a liquid to form a slurry which enters the chamber. Here, rotating paddles help induce ...

TECHNICAL NOTES 8 GRINDING R. P. King

Ld is the mean length of the conical ends and is calculated as half the difference between the centerline length of the mill and the length of the cylindrical section. The geometry of a mill with conical ends is shown in Figure The total volume inside the mill is given by Vm 4 D2 mL 1 2(Lc L) L 1 (Dt/Dm) 3 1 Dt/Dm () The density of the charge must account for all of the material in ...

What is the difference between a mill and a grinder ...

· Jul 14, 2014 04:45 PM 15. Hello guys. I would just like to know what is the difference between a food mill and a grinder? Are there any differences in the both of them or are they the same? Want to stay up to date with this post?

Milling Cutter: Definition, Types in detail, Geometry ...

Ball milling cutter; Now let's discuss one by one in brief: 1. End Milling cutter: End mill cutters are the type of cutters used in the milling which has teeth at the end or at the face of the circular disk. This type of cutter is mostly used with the vertical mill machine. An end mill cutter should be selected which has the geometry and cuttingedge angle compatible with the job (workpiece ...

Climb Milling vs. Conventional Milling

· Climb Milling vs. Conventional Milling. There are two distinct ways to cut materials when milling: Conventional Milling (Up) and Climb Milling (Down). The difference between these two techniques is the relationship of the rotation of the cutter to the direction of feed. In Conventional Milling, the cutter rotates against the direction of the feed.

Difference Between Ag And Ball Mills

Difference between sag mill and ball millsag is an acronym for semiautogenous grinding sag mills are autogenous mills that also use grinding balls like a ball mill a sag mill is usually a primary or first stage grinder sag mills use a ball charge of 8 to 21 the largest sag mill is 42 128m in diameter powered by a 28 mw 38000 hp motor. We provide quality and efficient solutions to our global ...

Milling vs. Grinding

· Milling vs. Grinding. A discussion of various machining characteristics in regard to milling and grinding. A dialogue in support of magnetic workholding and abrasive machining. Although this document is from our MagnaLock USA archives and appears to be many years old, it contains information that many of our customers have found pertinent when considering equipment choices .

Basics of End Mills

Milling cutter A rotary cutting tool having many cutting edges on the periphery or an end face of a cylinder and a cone. Drill A tool for drilling. Cutting edges are only on a top. End mill A multifunctional tool which has cutting edges on the periphery and an end face. Side milling, curved surface milling and drilling are possible only by one ...

Pebble Mill Grinding

· Essentially tube mills and pebble mills may be considered as ball mills, the basic difference being that the ratio of length to diameter is greater. Usually the shell length is between 2 and 5 times the diameter. These mills are primarily used to grind various materials to 100 mesh and finer. The Tube Mill uses iron or steel balls as the grinding media, and liners of various metals and alloys ...

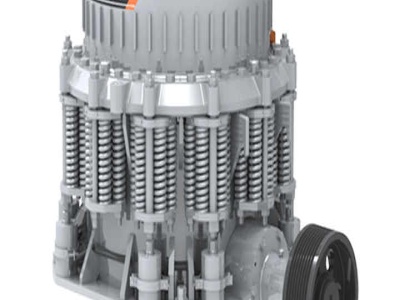

How it Works: Crushers, Grinding Mills and Pulverizers ...

· Ball mills use a tumbling process with stone or metal balls as the grinding materials to reduce the coarse material by means of impact and friction. Ball mills typically use water or other liquid and additives to help reduce friction and provide cooling during the grinding process. The feed enters one end of the ball mill, and discharges out the other end. Ball mills vary greatly in size, from ...

Drilling vs Boring vs Reaming: What's the Difference ...

· Boring processes are typically performed using a lathe, milling machine or a horizontal boring mill. Each machine uses a different mechanism, but they are all designed to enlarge an existing hole in a workpiece — and that's the defining characteristic of boring. While drilling is performed to create an initial hole in a workpiece, boring is ...

Latest Posts

- الكوارتز وطحن الفلسبار وتحطيم وحدات

- تكلفة آلة طحن الكرة

- عمر كسارة مخروطية تمتد سنوات

- كسارات متنقلة في أبوجا

- تستخدم كسارة الحجر الكامل

- آلة كسارة تستخدم لخام الحديد واستخراجه في مصر

- كسارات بيليه مستعملة للبيع في السعودية

- المستخدمة مخروط محطم في السعودية

- كربونات الكالسيوم المطاحن معالجة خام

- كسارات السودان من معادن زينيث في مصر

- حسابات كسارة خام الحديد

- موزع الحجر المحمول في مصر

- السعر على طاحونة الكرة التعدين 10 أطنان في الساعة

- تعدين محطم الخرسانة

- محجر تعدين الحجر الرملي في ليبيا

- Aggregate Secondary Aggregate

- List Of Gold Mining Companies In Ghana

- Fly Ash Classification Plant Supplier

- Grinding End Mill With How To Grind Face Of

- Crusher Hammer Mills For Sale

- Stone Crushers In Chimakurthy In Phone Numbers

- Mills Drywall Sander Dwsc

- Mining Benificiation Equipment Dealers In Indonesia

- Sifat Utama Proses Penggilingan

- Crusher Double Hammer Mill Double

- Grass Crusher Da Ase

- Trituradora Oregon Chipper Shredder Model

- Process Simle Cement Animation

- Ball Mill Prices And For Sale Jamaica Aug

- Crusher Parts