Suspension Aseptic Ball Milling

Suspension Aseptic Ball Milling

Suspension Aseptic Ball Milling. Mortar Grinder RM 200 for reproducible results RETSCH. The Mortar Grinder RM 200 can mix and homogenize powders, suspension and pastes, even for samples with high viscosity. The RM 200 is suitable for the proper and reproducible sample preparation to analytical fineness. The sample grinder substitutes cumbersome hand mortars by a high performance .

Effects of ball milling time and dispersant concentration ...

Effects of ball milling time and dispersant concentration on properties of a lead zirconate titanate aqueous suspension for tape casting Nisanart Traiphol* Department of Materials Science, Faculty of Science, Chulalongkorn University, Bangkok 10330, Thailand This contribution explored the effects of ball milling time on properties of a lead zirconate titanate (PZT) aqueous suspension. The ...

Optimization of formulation and process parameters for the ...

· The resulting suspension was wet milled with two different grinding media ( mm and mm diameter beads) using a planetary mill, model PM400 (Retsch Inc., Newtown, PA, USA), equipped with several zirconia milling chambers with chamber volumes of 50 mL. The movement of the milling beaker can be best described as lunar, which rotates about the planetary axis. In addition, the milling .

INTERNATIONAL JOURNAL OF SCIENTIFIC TECHNOLOGY .

However, most SSGM ball milling facilities dispose of contaminated wastewater untreated to the tailings pond and overflows to the rivers and creeks in the area. This wastewater contains broad range of suspended solids and with high concentration of heavy metals which are detrimental to the environment and people living nearby [3], [6]. In the Philippines, most SSGM ball milling facilities have ...

Practical 1 : Ball Milling | TF Lab 1

· Title: Ball Milling. Sieve. The sieving process in this experiment uses a stack of sieves which have the smallest mesh above a collector tray followed by meshes which get progressively coarser towards the top of the stack. Objective: To grind the coarse salt to a smaller size by using a ball mill and to obtain the particle size distribution of the initial and the sieved final mixture ...

Emax

The High Energy Ball Mill Emax combines highfrequency impact, intensive friction, and controlled circular jar movements to a unique and highly effective size reduction mechanism. The grinding jars have an oval shape and are mounted on two discs respectively which move the jars on a circular course without changing their orientation. The interplay of jar geometry and movement causes strong ...

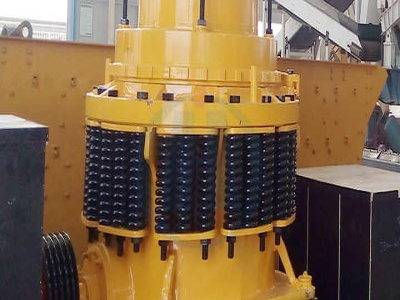

Ball Mills

· A ball mill efficiently operated performs a wide variety of services. In small milling plants, where simplicity is most essential, it is not economical to use more than single stage crushing, because the SteelHead Ball or Rod Mill will take up to 2″ feed and grind it to the desired fineness. In larger plants where several stages of coarse and fine crushing are used, it is customary to crush ...

suspension aseptic ball milling

suspension aseptic ball milling suspension aseptic ball millingGrinding Mill China Drug nanocrystals of poorly soluble drugs produced by high pressure The result is a suspension of drug In the knowledge of the potential problems associated with Chat With Sales » ball mill in suspension manufacturer ball mill parts ball ...

Suspension Aseptic Ball Milling

Suspension Aseptic Ball Milling. A silverson high shear batch mixer doesnt simply mix it emulsifies, homogenizes, solubilizes, suspends, disperses and disintegrates mixer, with its precisionengineered silverson rotorstator workhead, far outperforms conventional mixers, cutting processing times by up to 90, improving quality, product consistency and process.

Production of phenolics via photoalysis of ball milled ...

· Ball milling resulted in the formation of phenolic compounds even during dark mixing of the mixtures prior to photoalysis. Ball milled mixtures obtained using acetone and water resulted in a high yield of phenolic compounds after 3–4 hours of UV exposure. At long UV exposure periods, the phenolics production got saturated, possibly due to the deactivation of TiO 2 active sites by the ...

Sterile Drug Substance Manufacturers (7/94) | FDA

Aseptic isolation of the sterile substance by centrifugation or filtration. Aseptic drying, milling and blending of the sterile substance. Aseptic sampling and packaging the drug substance. These ...

Influence of micronization method on the performance of a ...

The purpose of this study was to investigate the influence of micronization technique on performance and stability of the model drug formulated in a suspensionbased pressurized metereddose inhaler (pMDI). The model drug, triamcinolone acetonide (TAA), was subjected to ball milling or airjet milli .

Spray drying | Hovione

Spray drying is a continuous process that can be used for multiple appliions. Over the last 15 years, the technology has been used for the production of solid dispersions and is the fastest growing platform to overcome the solubility issues related to oral drugs, it is also relevant to inhalable particles, specialty excipients and for the isolation of thermally labile products.

The Scalability of Wet Ball Milling for The Production of ...

Results: Comparable particle sizes of about 151 nm to 190 nm were obtained for both active pharmaceutical ingredients at the same milling time and milling speed when the drugs were processed at 10 g using low energy wet ball milling or 120 g using high energy wet ball milling in batch mode, respectively. However, an adjustment of the milling speed was needed for the 2 kg scale produced .

Ball mill

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the ...

Latest Posts

- مشروع من مصانع كسارة صغيرة الحجم الكيميائية

- طاحونة السطح آلات طحن الشخصية

- 1352 كسارة من خلال وضع

- تأثير المعلمات التقنية كسارة

- معدات سحق الحجارة المصنعة في المملكة العربية السعودية

- مخروط محطم المملكة العربية السعودية مصنع

- تكنولوجيا المعلومات حول كسارة الحجر

- تأجير كسارات الخرسانة المحمولة

- كامل ثمن النباتية المستخدمة محطم في الولايات المتحدة الأمريكية

- على نطاق صغير موردي المعدات التعدين الصين

- سحق متنقل ينتج

- معدات التعدين صغيرة للبيع

- pe400x600 كسارة الفك الصغيرة

- كسارة نوع كامل الصين

- duble التبديل المحمول كسارة الفك السعودية

- Maquinas Para Triturar Hielo Distribuidores

- Powerscreen Turbo Chieftain Dublin Price

- Granite Dust Machine

- Uk Hk Fdu L Dkhj Hg Pdk Tn Lwv

- Placer Gold Screening Machine

- Sorel Cement Testing

- Ultra Le Top Wet Grinder Ltrs Perfect Plus Price List

- Price Cone Peridot Crusher

- Buy Ultra Wet Grinder Online Barbados

- Air Water Machines Manufacturer

- Earthquake In Crusher

- Mining Equipment Hydraulic Cone Crusher Machine For Sale

- Of Cement Manufacturing Plant

- Sand And Gravel Mining Equipment For Sale

- Mi Er Grinder Branded